Installation method of L-shaped decoration integrated prefabricated parapet wall

An installation method and parapet technology, applied in roof insulation materials, building materials processing, roofing, etc., can solve the problems that cannot reflect the original intention of fast and excellent assembly, reduce the risk of anti-leakage, and reduce the construction period , The effect of eliminating hidden dangers of dangerous operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

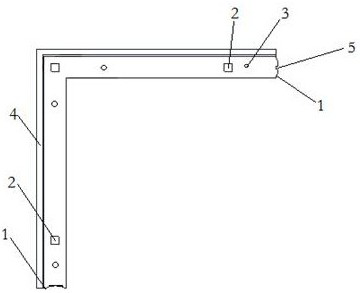

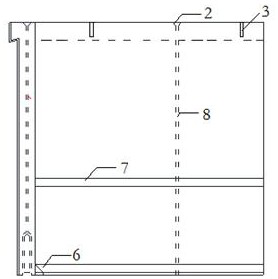

[0032] see Figure 1-3 , an L-shaped decorative integrated prefabricated parapet installation method, the installation method includes the following steps:

[0033] (1) Pretreatment: Clean up and increase the reserved connecting steel bars at the parapet of the roof to make it meet the positioning requirements;

[0034] (2) Hoisting: Use a tower crane or other hoisting equipment to hoist the prefabricated parapet wall in place through hoisting point 3, use temporary fixtures to fix the parapet wall, and adjust it in place;

[0035] (3) Closure: Use mortar or a special bandage to close the gap at the root of the prefabricated parapet wall to form a grouting warehouse;

[0036] (4) Grouting: Slowly pour the grouting liquid through the grouting port 2, observe the height of the grouting liquid at the other grouting ports 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com