Fan blade vibration reduction and parameter optimization method of power vibration absorber based on inerter

A technology for dynamic vibration absorbers and fan blades, which is applied in the directions of engines, wind turbines, machines/engines, etc., can solve the problems of narrow effective frequency band and insignificant vibration reduction effect, and achieves good universality, low cost and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

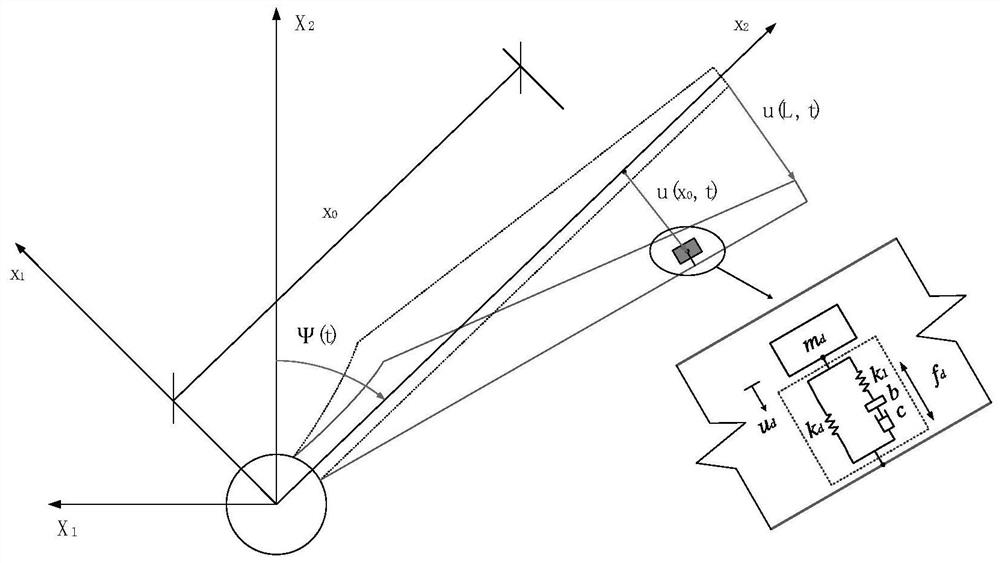

[0104] Taking the structural parameters of a NREL-5Mw fan blade as an example, its rated speed is Ω=1.27rad / s, and the basic modal mass is m 0 = 1354kg, blade length L = 61.5m, the basic mode shape function of the blade shimmy direction is

[0105]

[0106] Assume that the dynamic vibration absorber based on inertia is installed at a position 45m away from the root of the blade, that is, a=Φ(x 0 )=0.516, and the selected mass ratio μ=0.03. At this time, you can choose to set the proportional coefficient as n=0.3, m=1.255n+0.035.

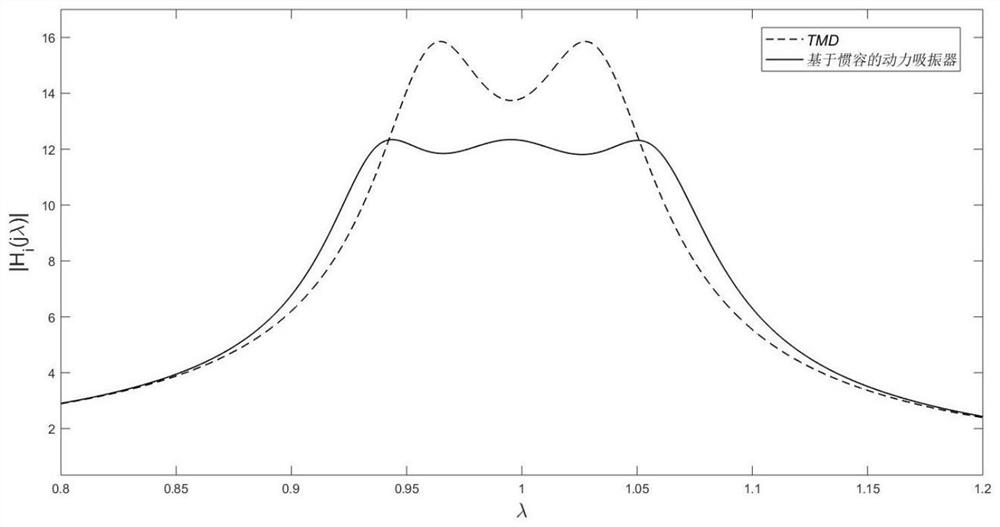

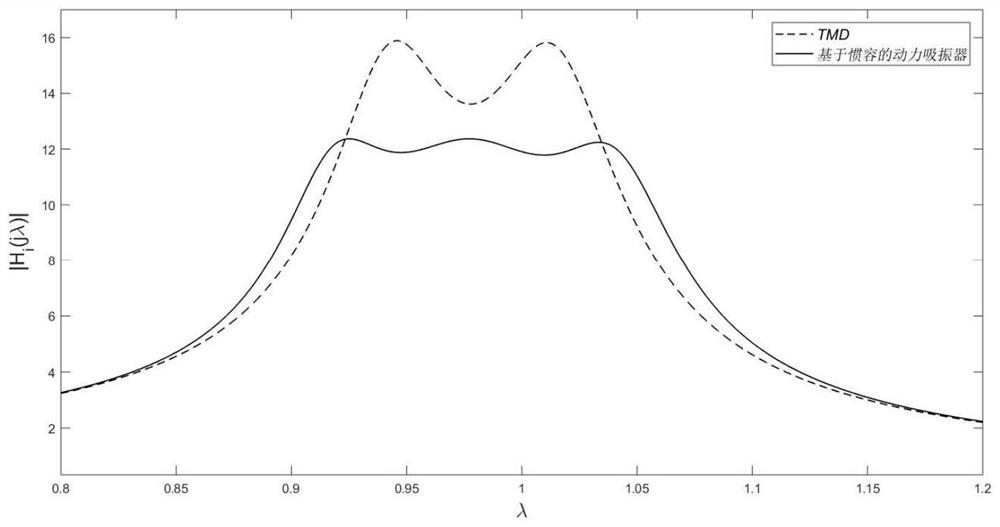

[0107] Firstly, the frequency domain performance of the dynamic vibration absorber based on inertia is verified. Figure 2(a) ~ Figure 2(c) is the frequency response curve of the displacement of the fan blade in the shimmy direction. Considering three different operating states (that is, Ω=0 corresponds to the shutdown state, Ω=Ω 0 The corresponding fan works at the rated speed and Ω=3Ω 0 Representing extreme cases), inertial-based dynamic vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com