Zero-sequence current pi control method with 2 degrees of freedom for open-winding permanent magnet motors

A permanent magnet motor, zero sequence current technology, applied in motor generator control, AC motor control, electronic commutation motor control and other directions, can solve the problems of complex parameter setting and structure of PR controller, and achieve simplified structure and parameters. Tuning process, overcoming the complex effects of parameter tuning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

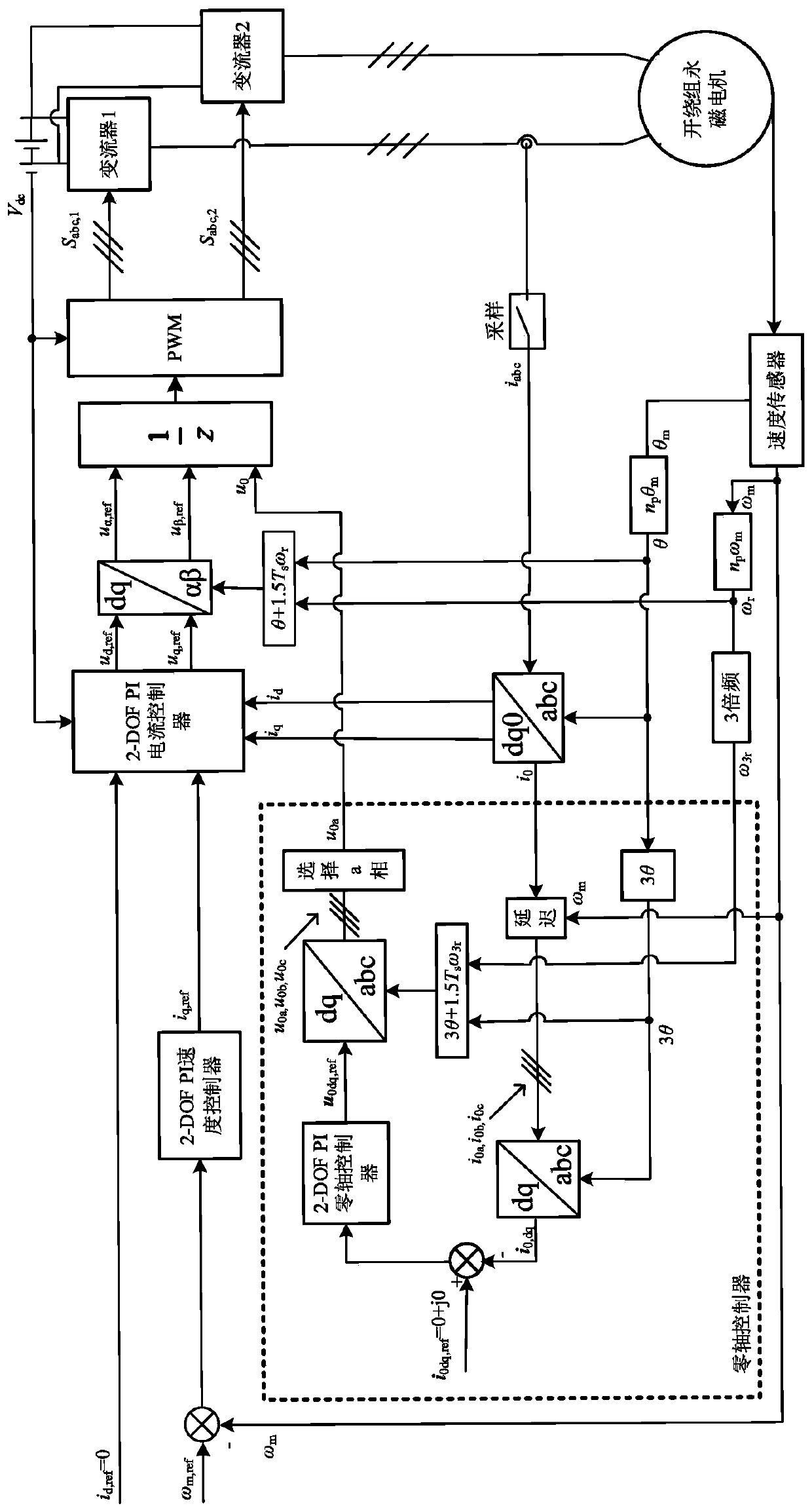

[0029] The embodiment of the present invention provides a common DC bus type open-winding permanent magnet motor control system, the control system adopts three closed-loop control, that is, the speed outer loop, the current inner loop, and the zero-sequence current control loop. The three control loops all adopt 2-DOF PI (2-DOF PI) controllers, and the speed outer loop and current inner loop are designed and adjusted by referring to existing literature, which is not explained in this patent. The zero-sequence current control loop is the core of the embodiments of the present invention, which will be described in detail in the embodiments of the present invention.

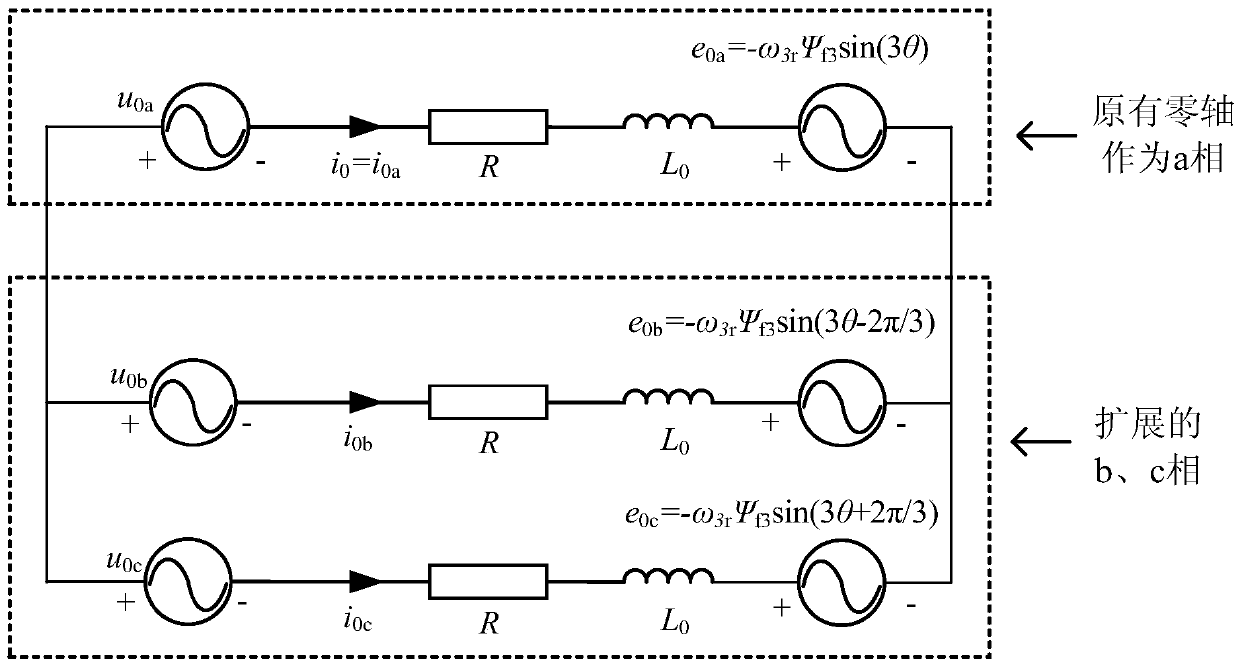

[0030] When only considering the third back EMF in the motor, the zero-sequence current in the motor mainly contains the third harmonic. In the embodiment of the present invention, after the zero-sequence current is obtained, the sampled zero-sequence current is respectively delayed by 120° after a certain time del...

Embodiment 2

[0035] Combine below Figure 1-Figure 3 , and the specific calculation formula further introduces the scheme in embodiment 1, see the following description for details:

[0036] figure 1 Shown is the zero-sequence current 2-DOF PI control structure diagram of the open-winding permanent magnet motor, and the speed outer loop and current inner loop are both controlled by 2-DOF PI. The design and parameter setting methods of the speed outer loop and the current inner loop refer to the traditional motor closed-loop control design method, and a large number of documents have explained this in detail, and the embodiments of the present invention will not repeat it here. The following focuses on the design of the zero-sequence loop controller:

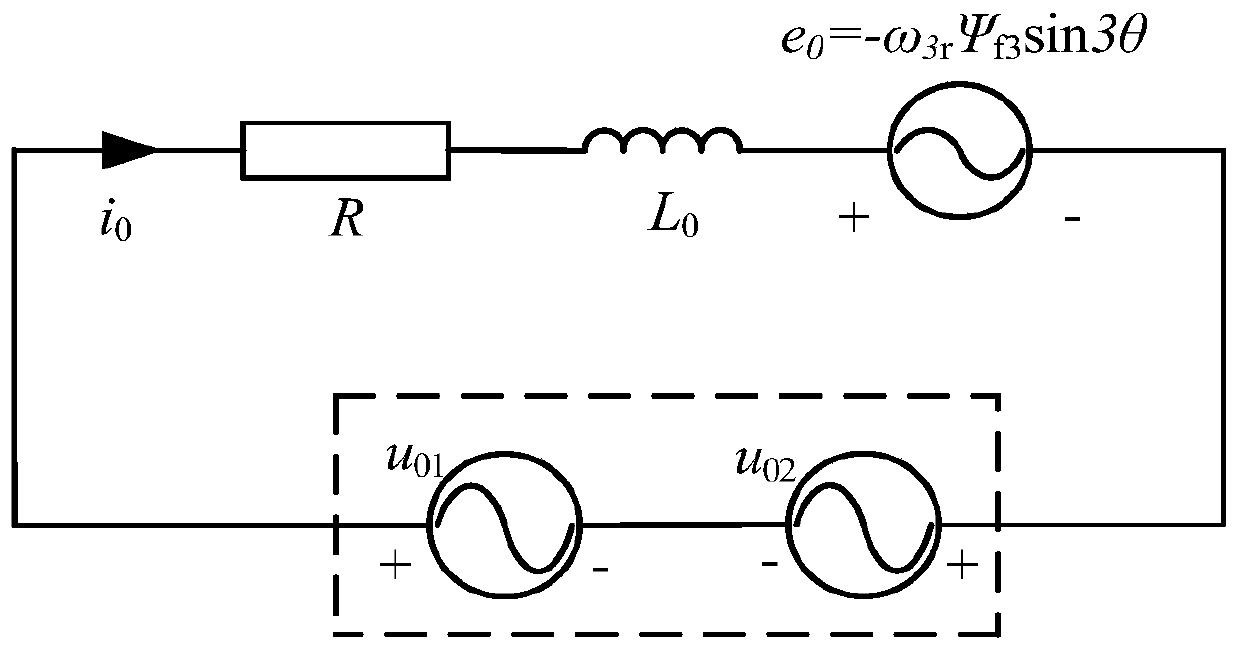

[0037] When power is supplied by dual converters, the common-mode voltages output by the two converters are respectively u 01 , u 02 , then the common-mode voltage u applied to the motor 0 for:

[0038]u 0 = u 01 -u 02 (1)

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com