Combustor, combustor module comprising combustor, combustor assembly and heating device

A technology of burners and pathways, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of high energy consumption, low thermal efficiency, high heat emission, etc., achieve long heat transfer time, reduce emissions, and increase area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

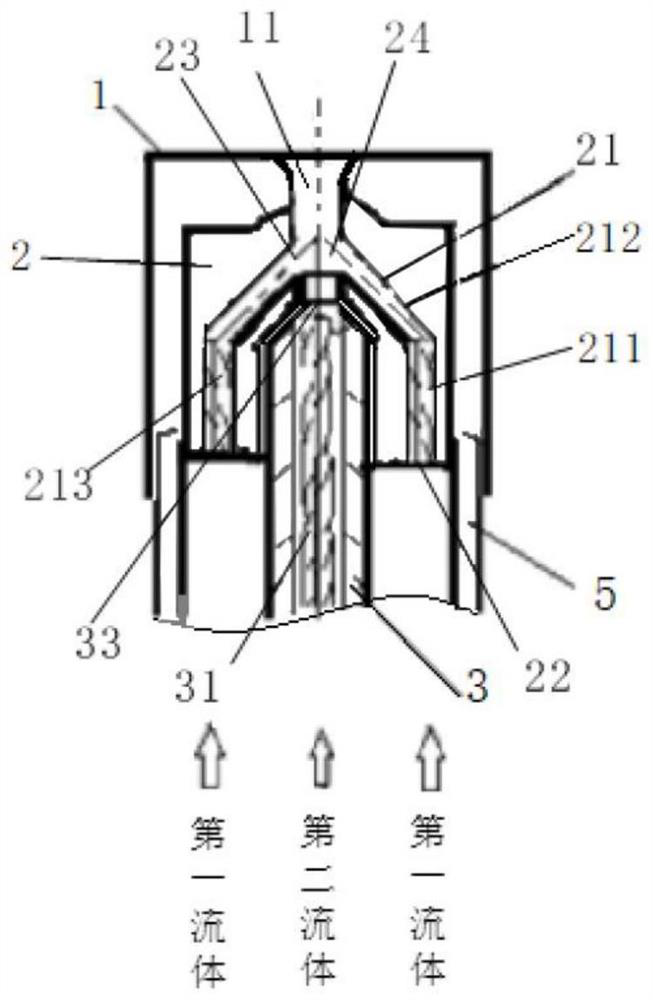

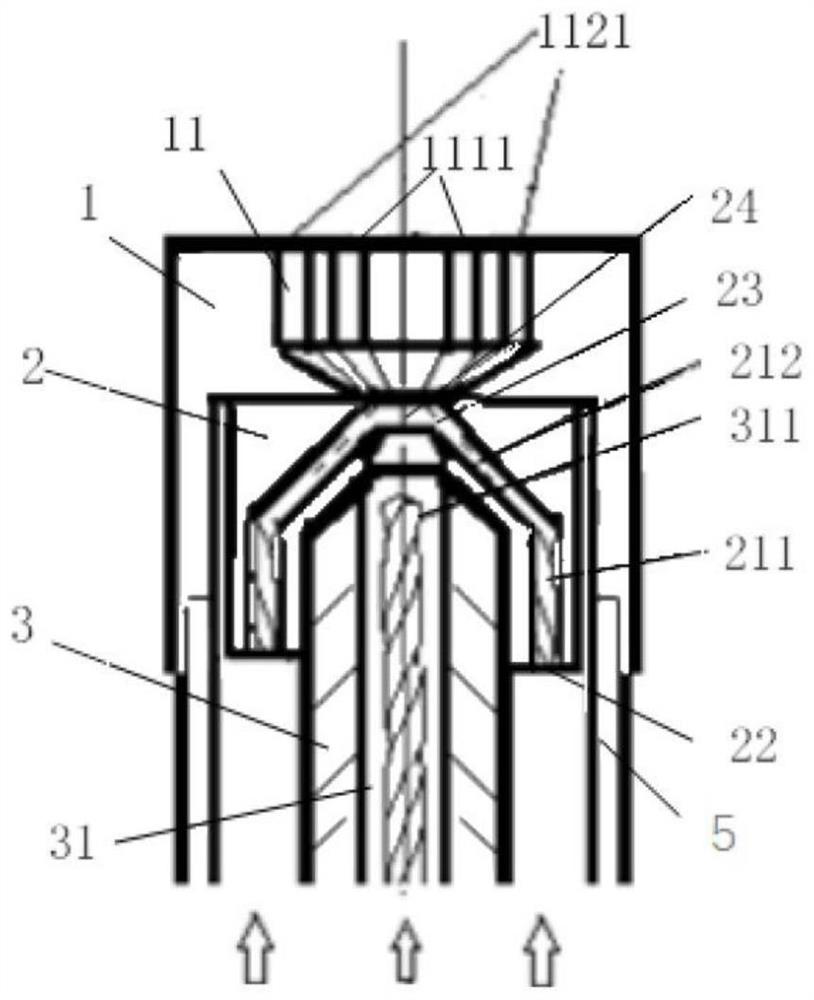

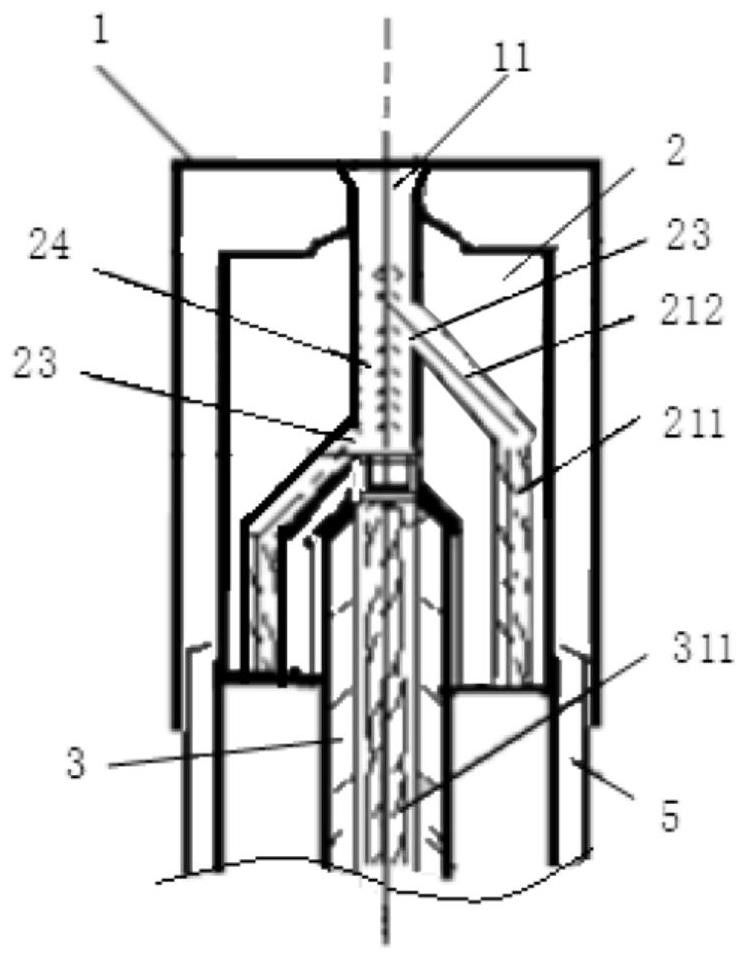

[0136] figure 2 A burner according to a second exemplary embodiment of the present invention is shown. In the second embodiment, a plurality of through passages 11 are formed in the nozzle 1, and the plurality of through passages 11 include inner passages and outer passages, wherein the outer outlets 1121 of the outer passages are located at the ends of the inner passages in the radial direction of the nozzle. outside of each internal outlet 1111. The sum of the cross-sectional areas of the outlets 1111 and 1121 of the plurality of through passages is greater than the cross-sectional area of the mixing passage 23 . exist figure 2 It is shown that each through channel 11 comprises a first portion extending from its inlet in a direction away from the axis of the nozzle and a second portion extending from the first portion in a direction parallel to the axis of the nozzle to the outlet of the through channel. two parts. With this structure, the first part of the plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com