Sealing performance detection cabinet, sealing performance detection system thereof and use method of sealing performance detection cabinet

A technology of sealing detection and detection cabinet, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve the problem of inability to accurately measure product sealing performance and judge with certain subjective factors , detection data cannot be quantified and other problems, to achieve the effect of novel and unique detection principle, elimination of human subjective factors, and elimination of subjective factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] This embodiment provides a leakproofness testing cabinet for testing the sealing performance of a container with an outwardly bent flange at the opening.

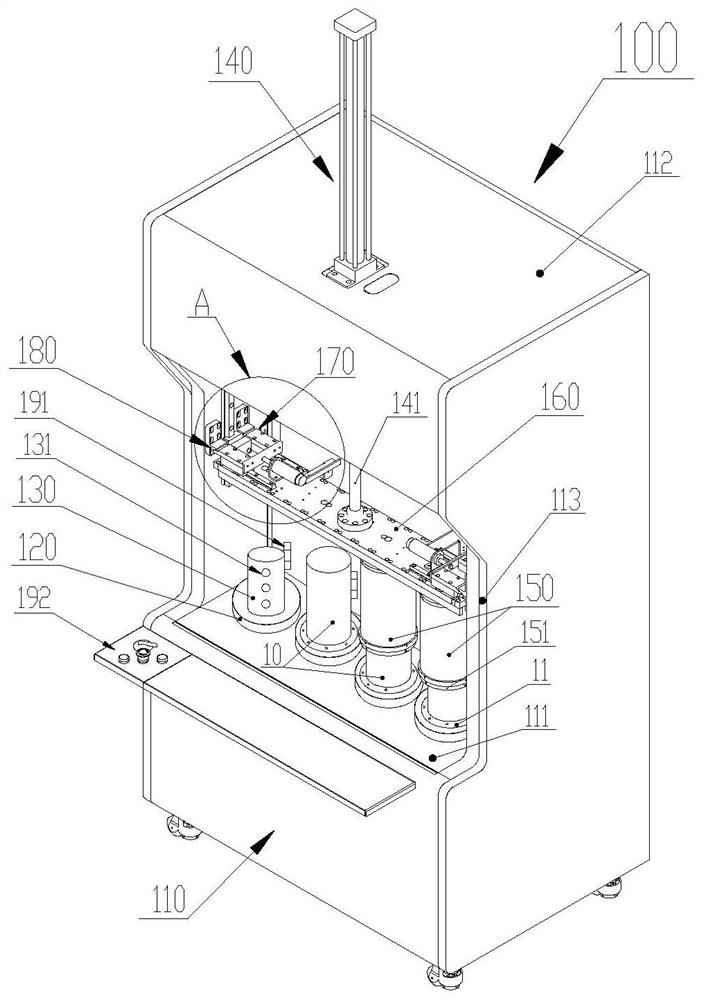

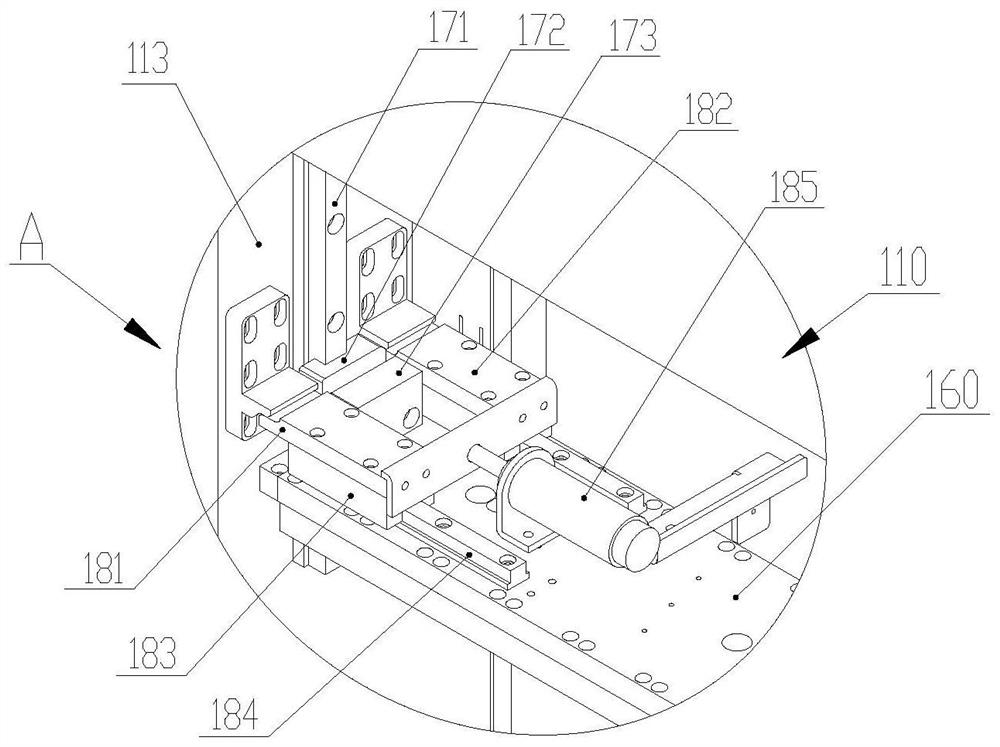

[0094] Such as figure 1 A schematic diagram of a three-dimensional structure of a leak detection cabinet provided by an embodiment of the present invention is shown as follows:

[0095] The container 10 involved in this embodiment has an outwardly bent flange 11 at its opening.

[0096] From figure 1 It can be seen from the figure that the leak detection cabinet 100 provided in this embodiment includes:

[0097] A cabinet body 110 with an operating platform 111 and a top cover 112;

[0098]The operating platform 111 is provided with a checker base 120, the checker base 120 is used to invert the container 10, the checker base 120 is also provided with a checker inner core 130, and the checker inner core 130 is provided with a gas outlet 131, when the container 10 When inverted on the inspection tool base 120, the ...

Embodiment 2

[0129] This embodiment provides a sealing performance testing system for testing the sealing performance of a container with an outwardly bent flange at the opening.

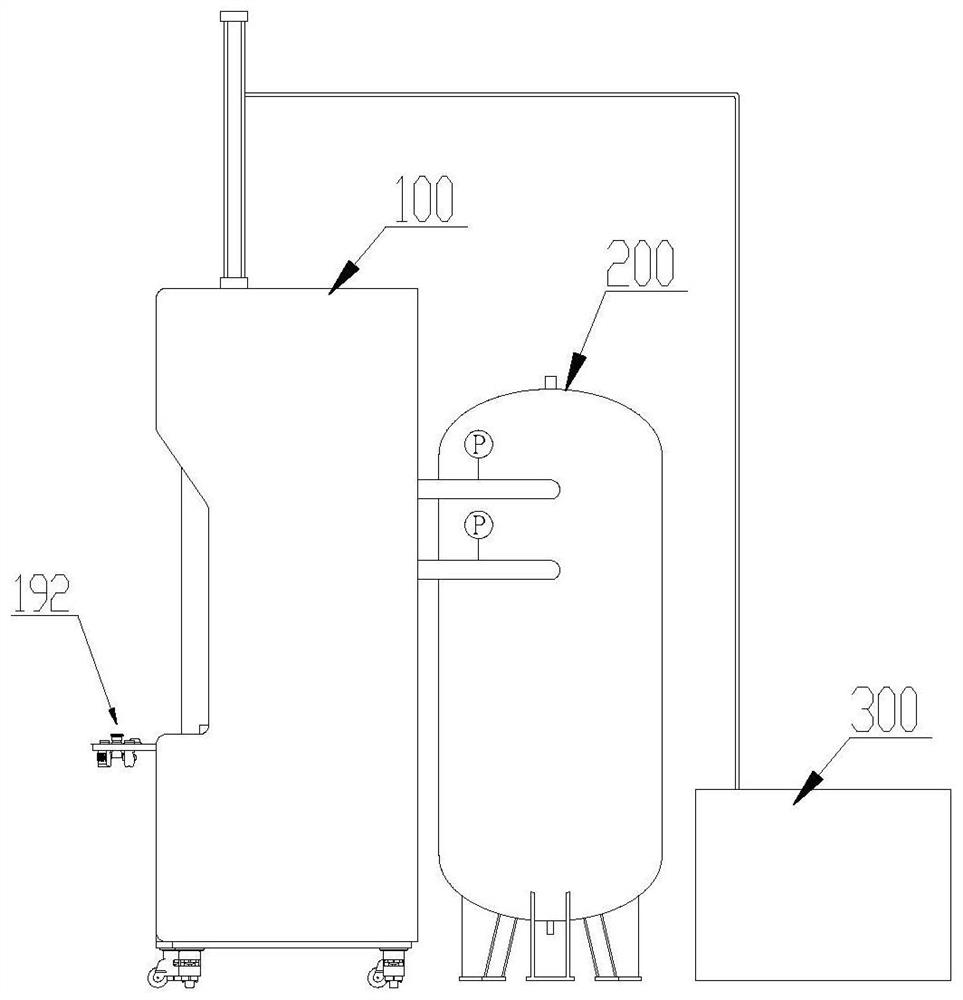

[0130] From image 3 A side-view structural schematic diagram of a leak detection system provided by an embodiment of the present invention, combined with figure 1 As can be seen:

[0131] The leak detection system provided in this embodiment includes:

[0132] The airtightness detection cabinet 100 provided by the above-mentioned embodiment 1, and the air pressure sensor inside the container (not shown in the figure), the air pressure sensor outside the container (not shown in the figure), the indicator light 191, the controller 192, and the gas buffer tank 200 and hydraulic controller 300, wherein:

[0133] The gas buffer tank 200 is respectively connected to the cylinder of the inspection tool inner core 130 and the inspection tool outer cover 150, and the gas buffer tank 200 respectively passes through th...

Embodiment 3

[0144] This embodiment provides an optimized airtightness inspection system for inspection of the airtightness of a container with an outwardly bent flange at the opening.

[0145] like Figure 4 A schematic diagram of the three-dimensional structure of a tightness detection system composed of double tightness detection cabinets provided by the embodiment of the present invention is shown as follows:

[0146] In the leak detection system provided in this embodiment, it includes:

[0147] Two airtightness testing cabinets 100, and the bottoms of the respective cabinet bodies 110 of the two airtightness testing cabinets 100 are respectively provided with pulleys 114, and the pulleys 114 are used for the movement of the respective airtightness testing cabinets 100:

[0148] The two airtightness detection cabinets 100 are distributed in a fan shape, and the respective controllers of the two airtightness inspection cabinets 100 are combined into one master controller 193, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com