Fatigue monitoring method and life prediction method of quay crane structure

A kind of fatigue monitoring and scheme technology, applied in the direction of instrument, design optimization/simulation, calculation, etc., can solve the problems of fatigue failure, cracks in the stress concentration part of lifting machinery, complex stress of lifting machinery, etc., to improve the accuracy and precision high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

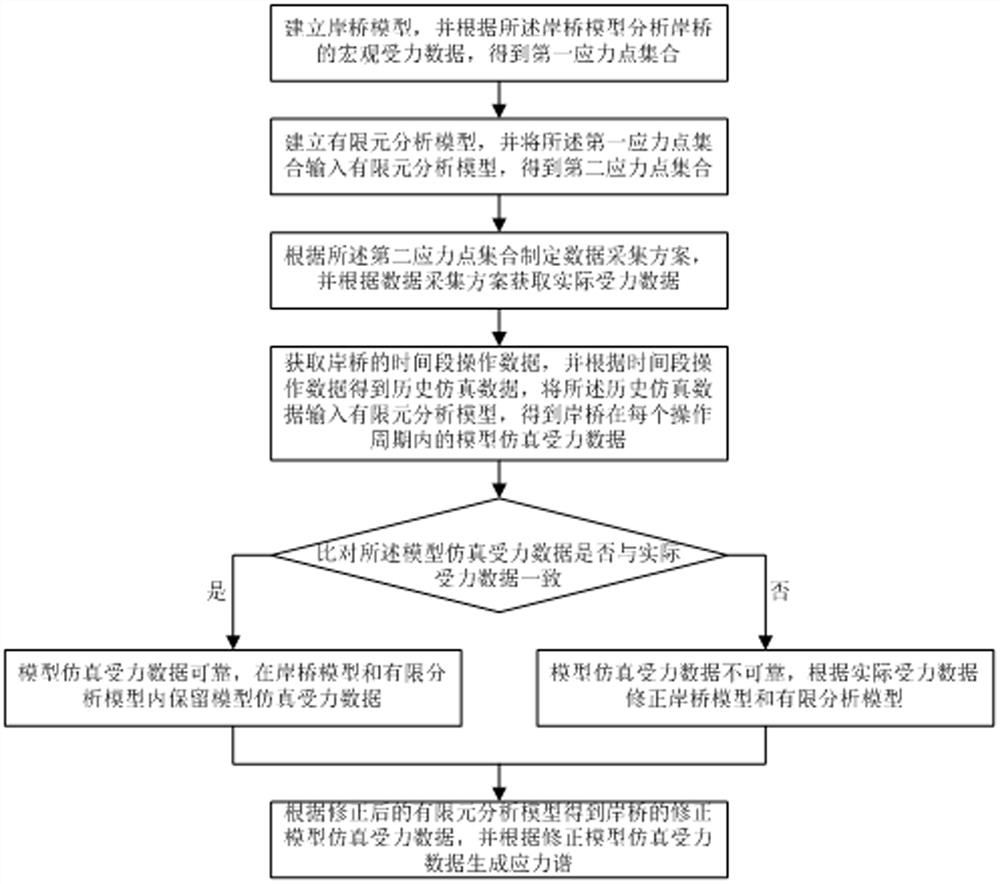

[0047] Such as figure 1 As shown, a fatigue monitoring method for a quay bridge structure includes the following steps: establishing a quay bridge model, and analyzing the macroscopic force data of the quay bridge according to the quay bridge model, and obtaining the first stress point set, specifically, including the following steps: Obtain the structural drawings and operating data of the quay crane, and build the quay crane model according to the structural drawings; input the operating data into the quay crane model, and after completing the input of the operating data, output the macro force data of the quay crane to obtain the first A set of stress points.

[0048] When analyzing the stress points of the quay bridge structure, firstly, the quay bridge model is established by using OpenSees, and the quay bridge model uses the structure drawing of the quay bridge as the input data of the model, so as to simulate the real quay bridge in the quay bridge model And the operat...

Embodiment 2

[0061] A life prediction method for a quay bridge structure, comprising the following steps: obtaining design parameters of the quay bridge, and outputting a stress fatigue curve according to the design parameters; constructing a life prediction model according to a linear fatigue damage model and a stress fatigue curve, wherein the life prediction model is passed The stress spectrum is used as data input; the life prediction curve is output according to the life prediction model, and the life value of the quay crane is obtained, and the following steps are also included: outputting the maintenance and inspection plan of the quay crane according to the life prediction model.

[0062] In this embodiment, the establishment of the life prediction model first needs to obtain the stress spectrum output from the finite element analysis model obtained in the first embodiment as the input of the life prediction model, and the acquisition of the stress spectrum is obtained according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com