Rapid assembly equipment for photovoltaic copper sheet diode

A technology for assembly equipment and diodes, applied in welding equipment, auxiliary welding equipment, metal processing equipment, etc., can solve the problems of low assembly efficiency and achieve the effects of saving labor costs, high efficiency, fast and accurate placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

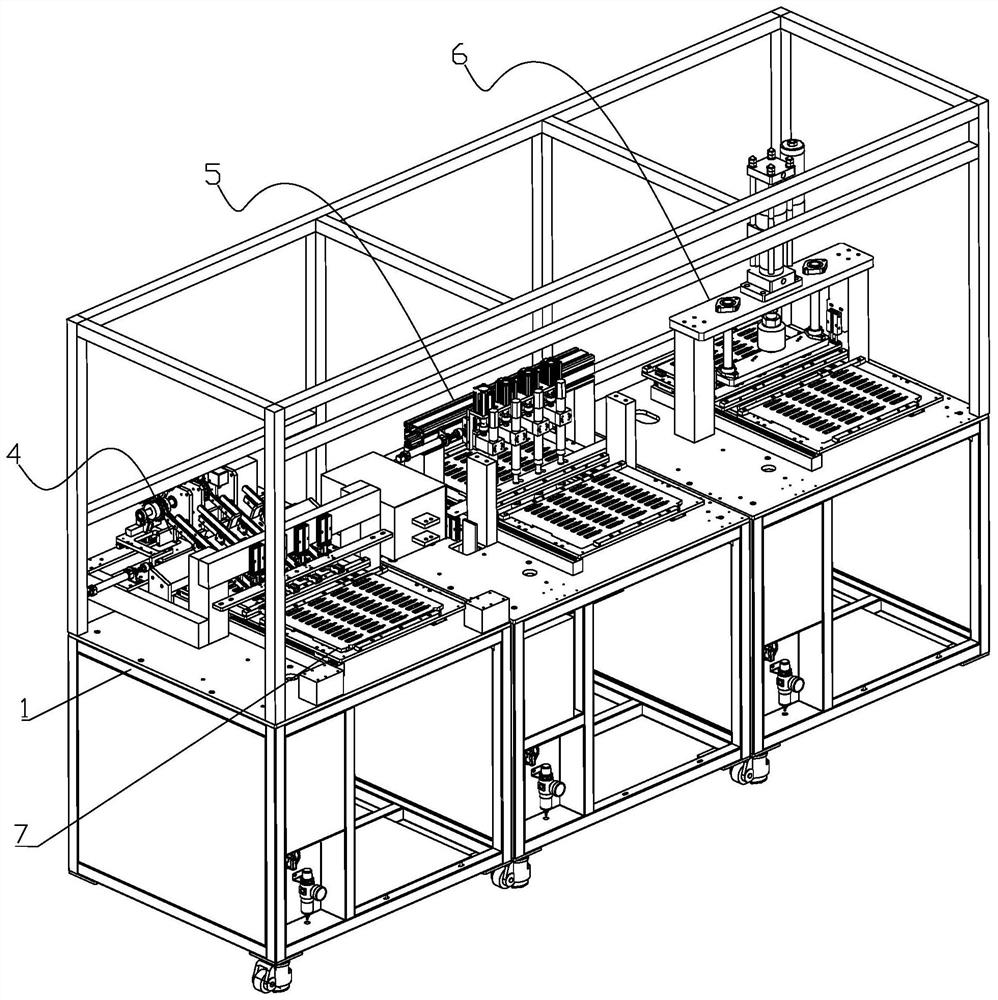

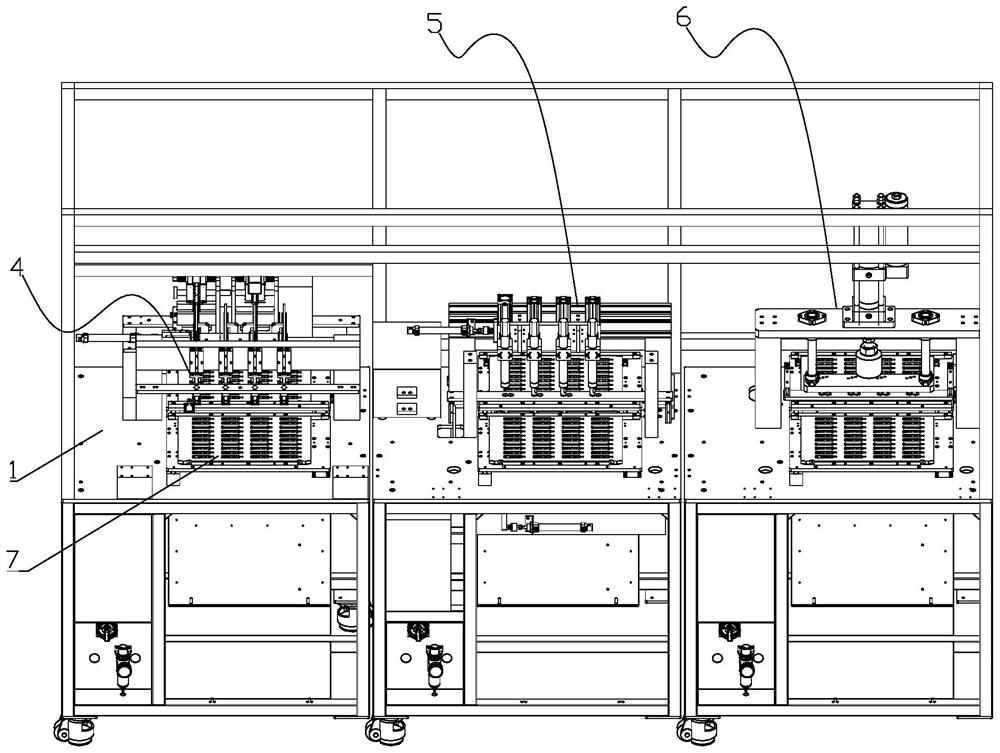

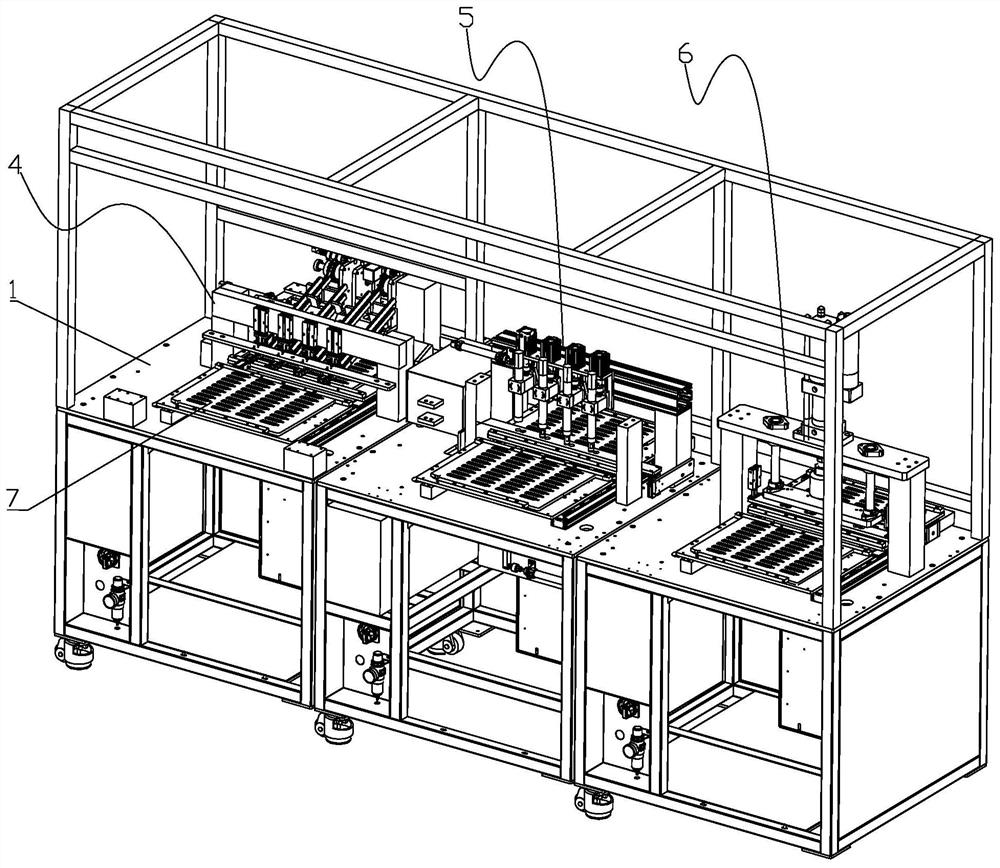

[0024] see Figure 1-Figure 6 , a photovoltaic copper sheet diode rapid assembly equipment, in this embodiment, includes a machine 1, the machine 1 can be a mobile machine or a fixed machine, the former is suitable for small production workshops, and the latter is suitable for medium or Large production workshop. The machine 1 is provided with a feeding device 4 for assembling the copper sheet 2 and the diode 3, a welding device 5 for welding the diode 3 and the copper sheet 2, and a cutting device 6 for separating the copper sheet 2. Table 1 is divided into three operation areas of feeding, welding and cutting, which correspond to feeding device 4, welding device 5 and cutting device 6 respectively, so as to realize the assembly of diodes and copper sheets. The feeding device 4, welding device 5 and cutting device The devices 6 all include a material plate 7 for placing the copper sheet 2 .

[0025] The feeding device 4 includes a raw material advancing part 8 for providing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com