Intelligent management system of steel rail welding production line and steel rail welding production line

A welding production line and management system technology, which is applied in manufacturing computing systems, data processing applications, program control in sequence/logic controllers, etc., to achieve the effects of improving dynamic response capabilities, improving work efficiency and operating reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

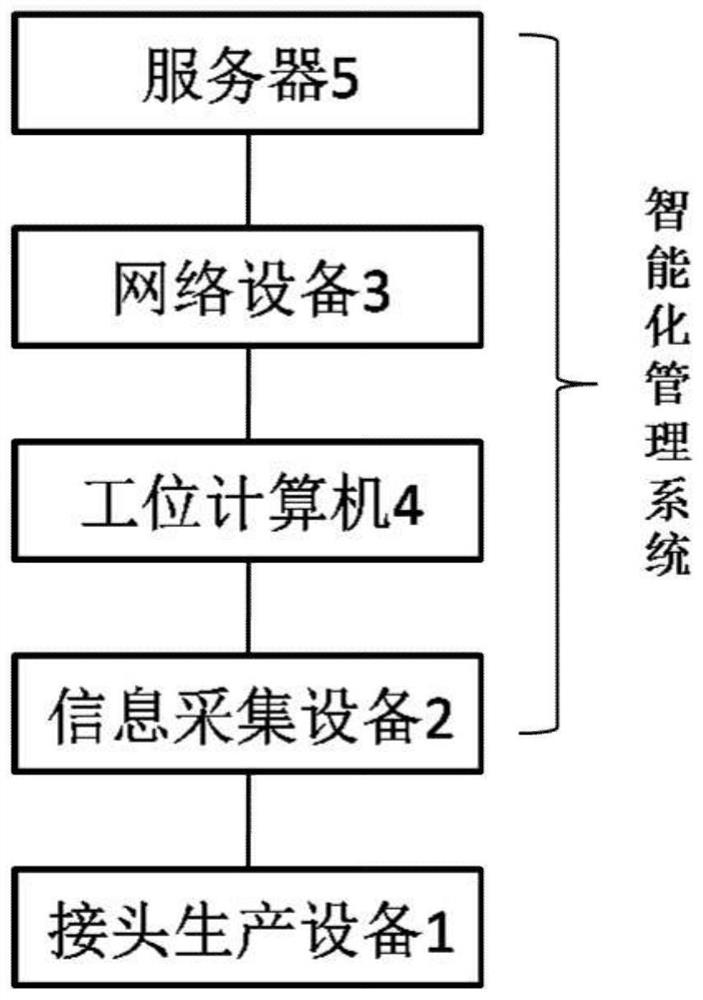

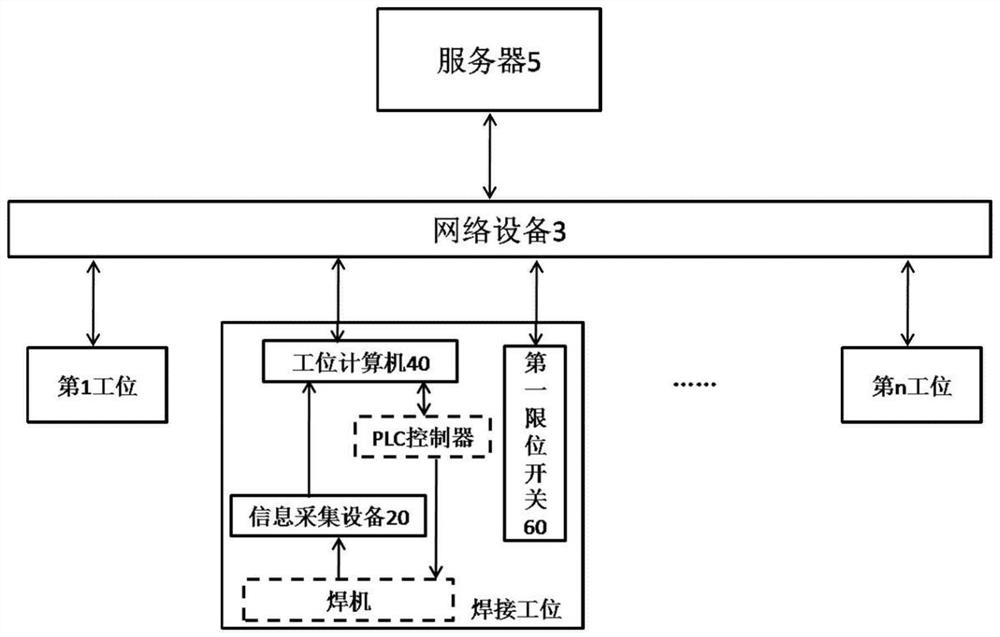

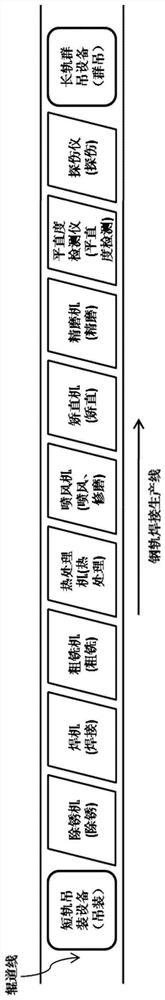

[0023] figure 1 It is a block diagram schematically showing the overall structure of a rail welding production line including an intelligent management system according to an embodiment of the present invention. The overall structure of the rail welding production line including the intelligent management system according to an embodiment of the present invention is as follows: figure 1 As shown, it includes joint production equipment 1 , information collection equipment 2 , network equipment 3 , workstation computer 4 , and server 5 . Joint production equipment 1 mainly includes rust remover, welding machine, rough milling machine, heat treatment machine, blower, straightening machine, fine grinding machine, appearance inspection flatness instrument, flaw detector. The working area where each equipment is located is called a station, for example, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com