Natural color yarn processing device

A processing device and yarn technology, applied in the field of yarn, can solve the problems of low yarn strength and tenacity, low yarn tenacity, etc., and achieve the effects of increasing tenacity and tightness, achieving stretching effect and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

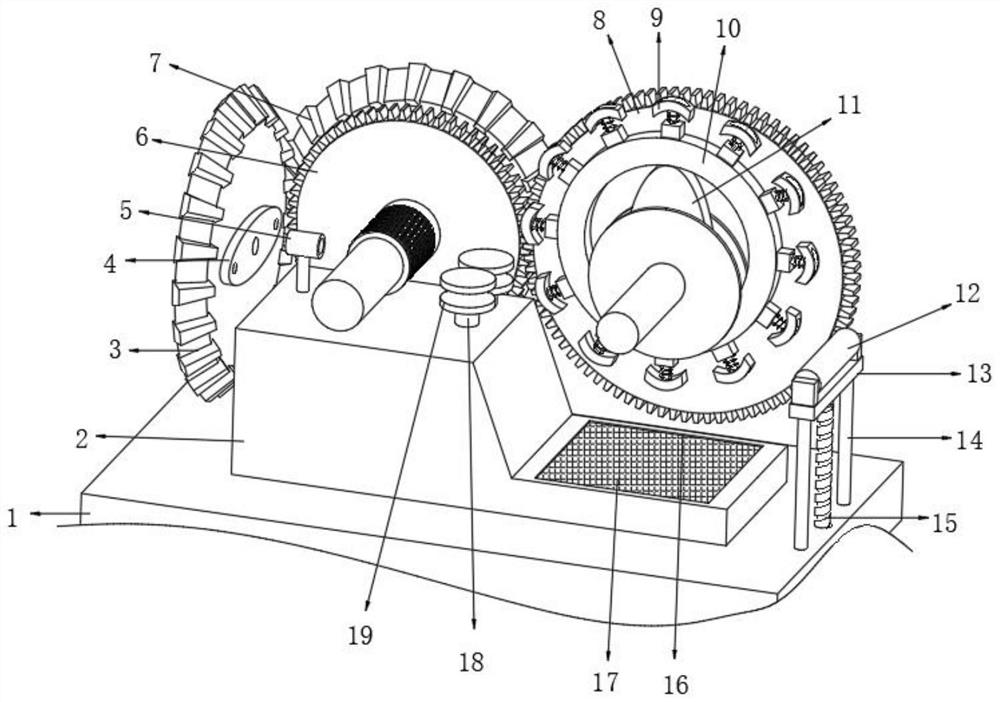

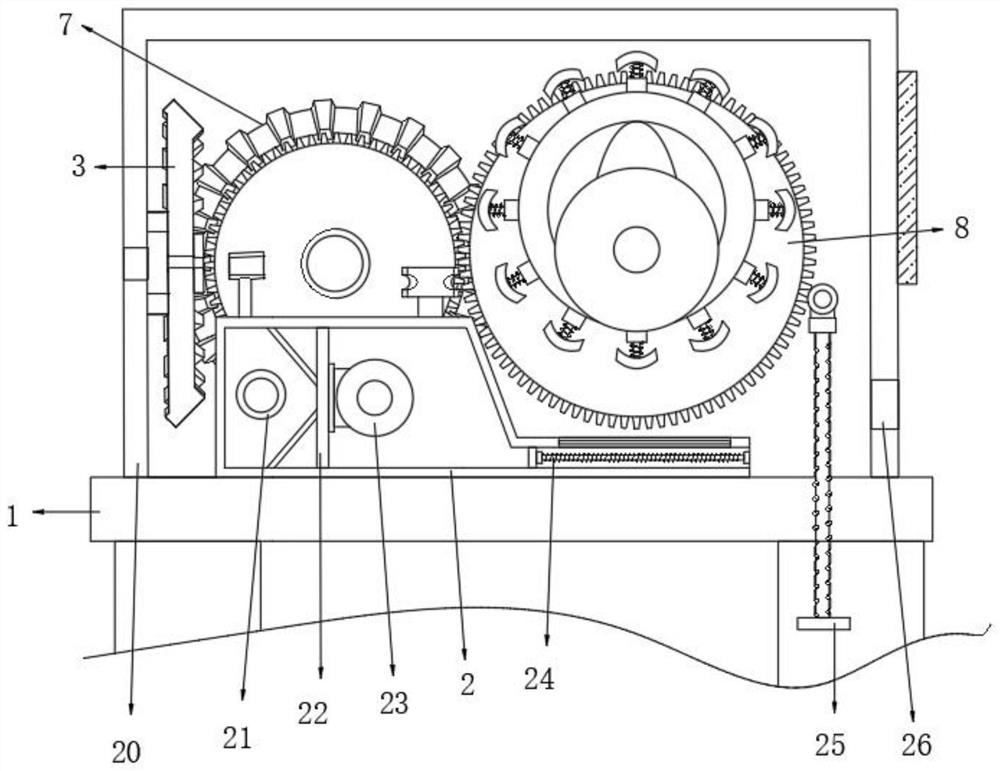

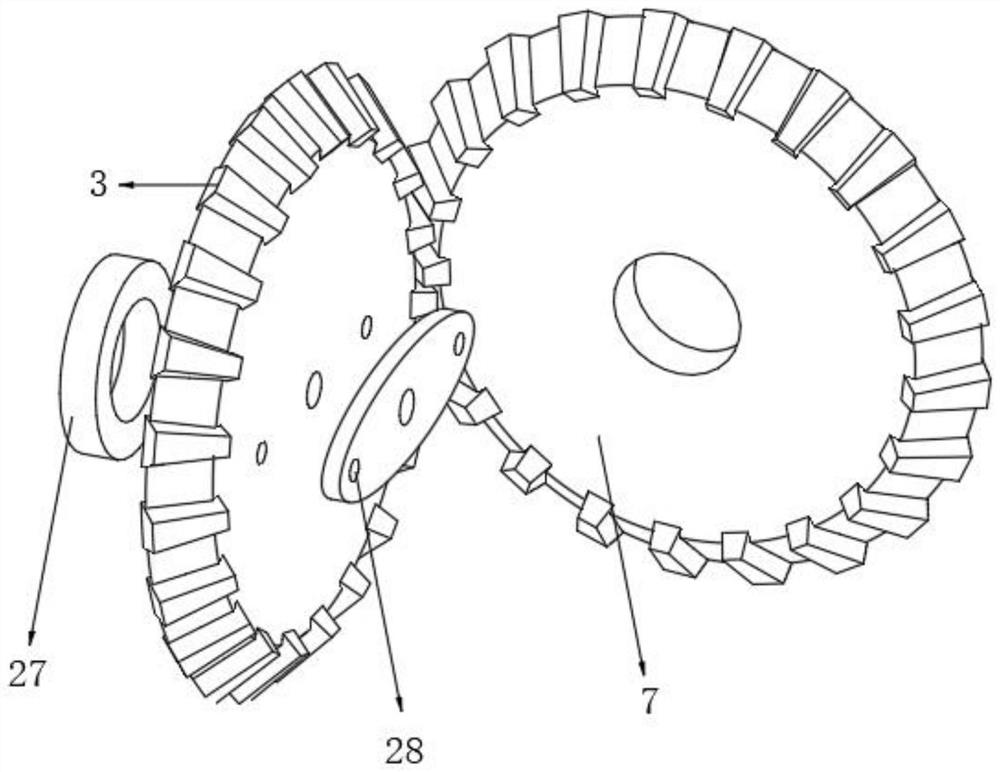

[0031] refer to Figure 1-6, a processing device for uncolored yarn, comprising a bottom plate 1, a receiving platform 2, a cam 11, a limit roller 12 and a top box 20, the top box 20 is connected to the top outer wall of the bottom plate 1 by bolts, and one end of the top box 20 There is a wire inlet hole in the middle position, and there is a wire outlet hole 26 between the outer walls of the bottom of the other end of the top box 20. The receiving platform 2 is connected to the top outer wall of the bottom plate 1 by bolts, and the inner wall of the receiving platform 2 is provided with an air intake mechanism. The inner wall of the other end of the top box 20 is connected with a second rotating rod 31 by bearing rotation, and the peripheral outer wall of the second rotating rod 31 is provided with a stretching mechanism, and the other end of the outer wall of the top case 20 is connected with a Drive motor, one end of the output shaft of the drive motor is connected to one ...

Embodiment 2

[0041] refer to Figure 7 , a processing device for uncolored yarns. Compared with Embodiment 1, the inner wall of the thread pipe 5 is connected with a mounting platform 38 by bolts, and the inner walls at both ends of the mounting platform 38 are connected by bearings. A plurality of threaded inner cylinders 39 are equidistantly distributed, and the circumferential outer walls of the threaded inner cylinders 39 are all provided with threaded structures.

[0042] Working principle: when a plurality of threaded inner cylinders 39 are installed inside the threading pipe 5, the three strands of the original wire will be further rotated and squeezed by the rotatable threaded inner cylinder 39 after the rotation of the threading plate 4, further The extrusion effect on the original line has been strengthened.

Embodiment 3

[0044] refer to Figure 8 , a processing device for uncolored yarn. Compared with Embodiment 2, this embodiment has electric heating rods 40 connected to the circumferential inner wall of the threaded inner cylinder 39 through bolts, and the electric heating rods 40 and the control panel are electrically connected.

[0045] Working principle: when the threaded inner cylinder 39 is provided with an electric heating rod 40, when the threaded inner cylinder 39 performs rotary thread extrusion on the original thread, the heat released by the electric heating rod 30 will strengthen the plasticity of the original thread, thereby strengthening the original thread. fit between lines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com