Reinforced corrugated plate box culvert structure

A corrugated plate and reinforced technology, applied in the field of box culvert structures, can solve the problems of easy deformation and poor support strength, and achieve the effects of avoiding cracking and deformation, fast construction speed and low construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

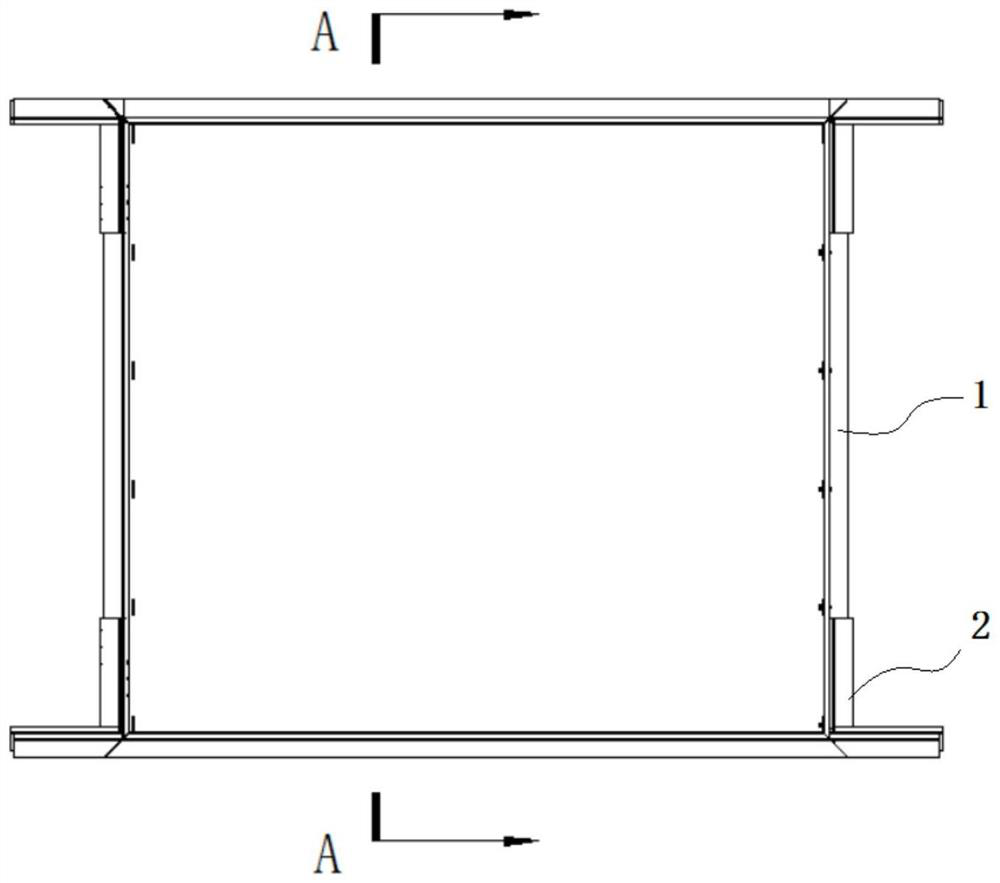

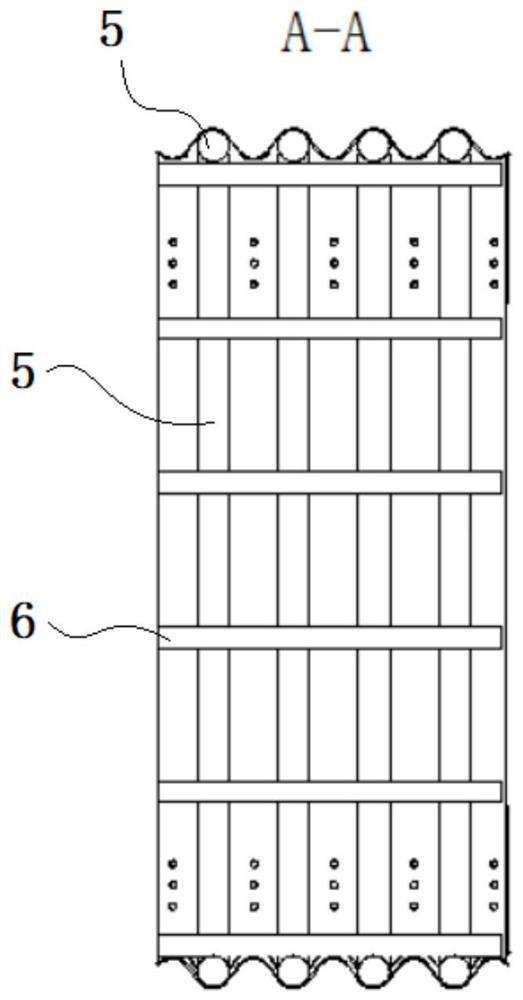

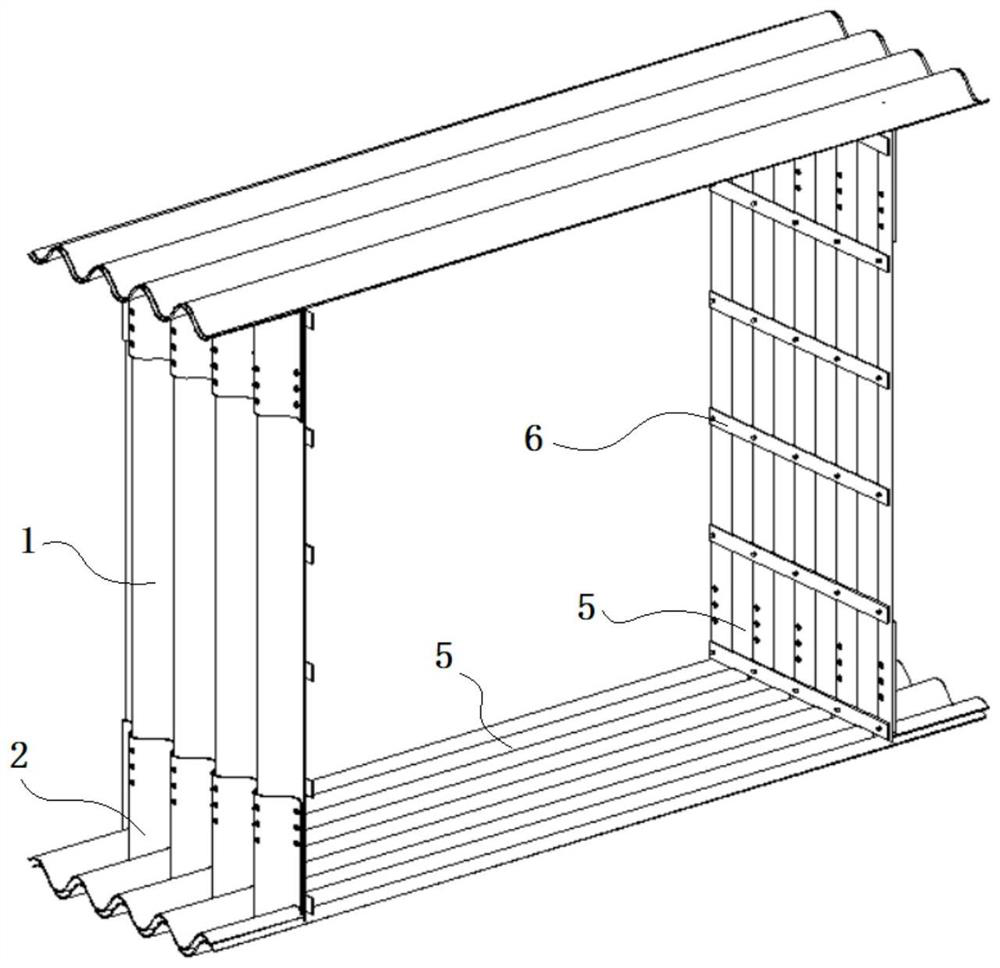

[0037] see Figure 1-Figure 3 The shown reinforced corrugated board box culvert structure includes four-sided panel unit 1, which are respectively upper, lower, left and right panel units. In this embodiment, the single-sided panel unit 1 includes multiple pieces of steel corrugated board 3. The edge corrugated troughs of multiple steel corrugated plates 3 are stacked face to face and then connected by bolts to form a whole piece of jigsaw unit 1. In other embodiments, after the edge corrugated troughs of multiple steel corrugated plates 3 are stacked face to face It can also be welded into a whole jigsaw unit 1; the upper, lower, left and right jigsaw units are vertically connected sequentially through prefabricated connectors 2 to form a closed box culvert structure.

[0038] In this embodiment, the upper and lower jigsaw units are slightly longer, and the left and right jigsaw units are arranged between the upper and lower jigsaw units to form a rectangular structure extend...

Embodiment 2

[0046] The difference from Embodiment 1 is that in this embodiment, the single panel unit is composed of a single steel corrugated plate, and the size of the steel corrugated plate matches the design size of the box culvert; between the upper and lower panel units Set the left and right jigsaw units, whose cross-section is a rectangular structure. In this embodiment, the connectors are corrugated inner angle steels, and the corrugated inner angle steels are bolted to the four inner corners of the box culvert structure through high-strength bolts, and the reinforcing pipes in the troughs of the steel corrugated plates are fixed inside; the same , multiple sets of reinforcing ribs can also be provided on the corrugated inner angle steel to strengthen the bending resistance and mechanical strength of the corrugated inner angle steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com