Cleaning device for flexible mechanical conveying

A technology of mechanical conveying and cleaning device, applied in the field of sanitation machinery, can solve the problems of fixed conveying posture, large power demand, and large size, and achieve the effect of reducing difficulty, simple structure and low power demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

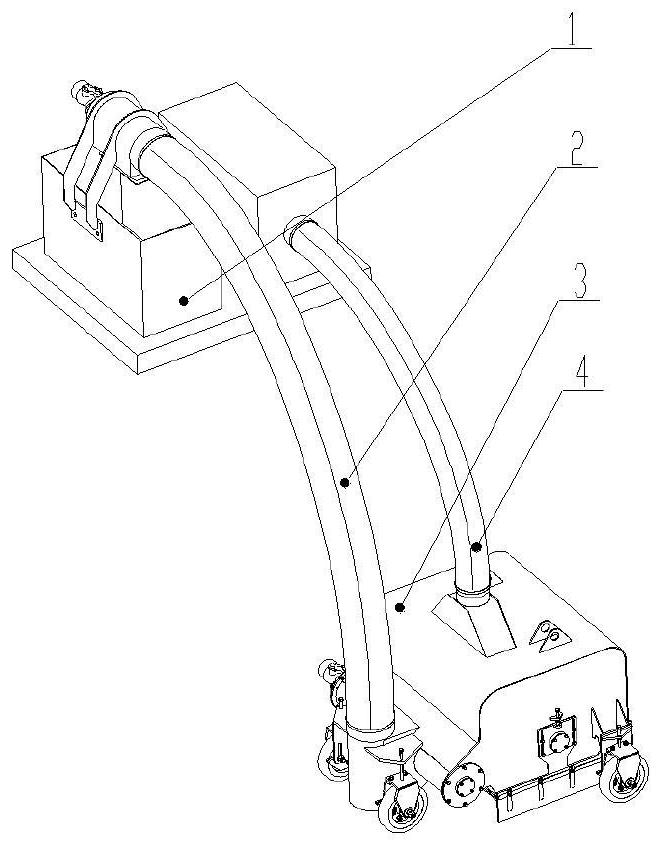

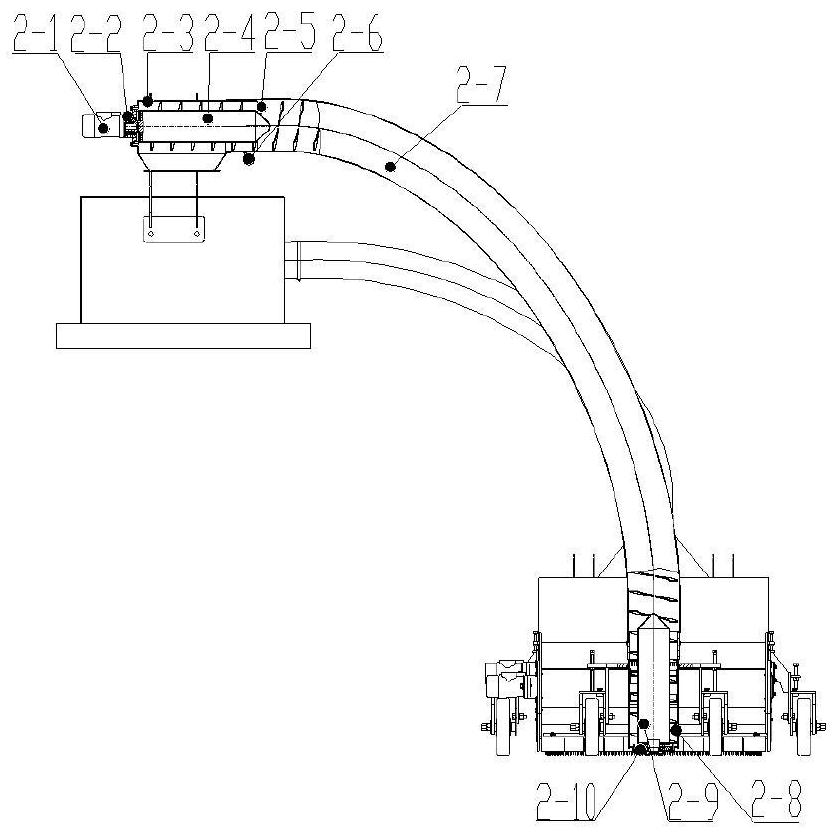

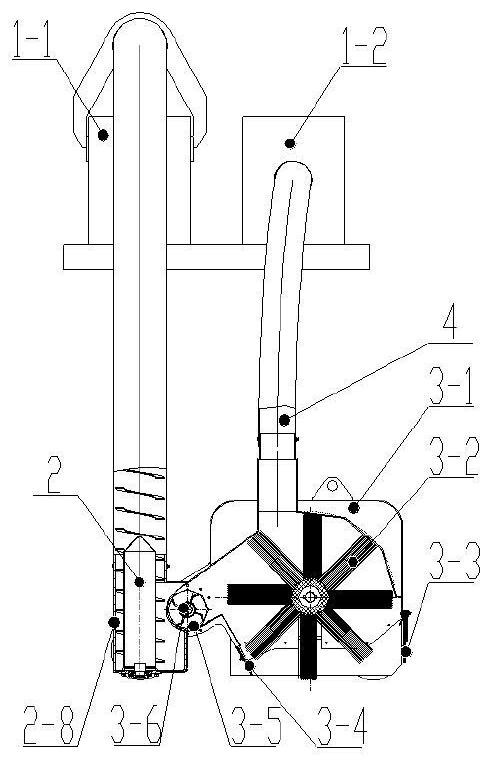

[0027] The cleaning device structure of a kind of flexible mechanical transportation of the present invention is as follows: figure 1 As shown, it is mainly composed of sanitation equipment base 1, flexible mechanical conveying mechanism 2, cleaning module 3, dust removal pipeline 4 and other parts.

[0028] The sanitation equipment includes a silo 1-1, a dust removal system 1-2, a power system, and the like. Among them, the dust removal system 1-2 pumps the cleaning module 3 housing into a negative pressure through the dust removal pipeline 4 to avoid dust overflow during cleaning, and the dust-laden gas generated at the same time enters the dust removal system 1-2 through this pipeline for fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com