Wall painting device for building engineering construction

A technology of construction engineering and brush head, applied in the direction of construction, building structure, etc., can solve the problem of high cost of use, and achieve the effect of expanding the scope and improving the painting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

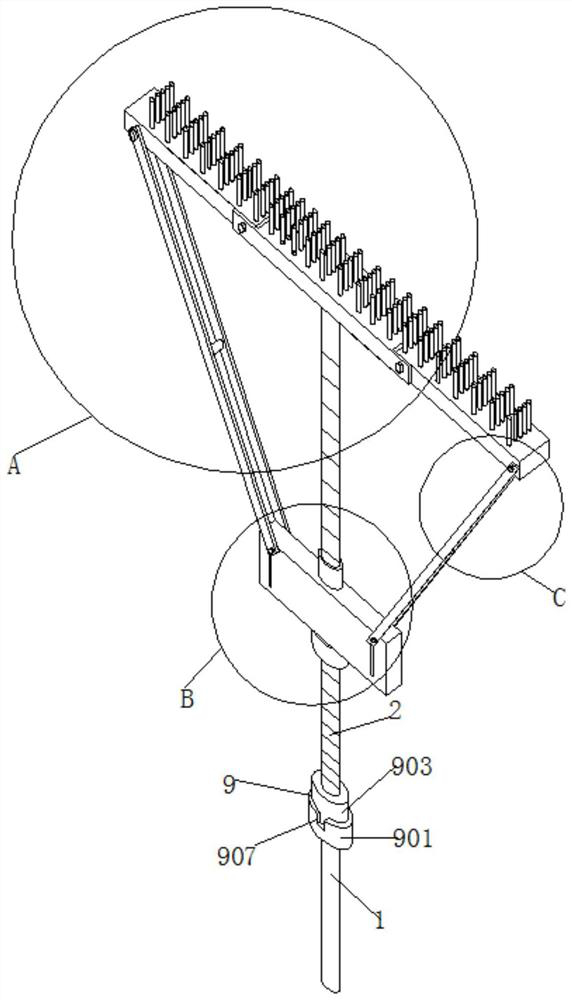

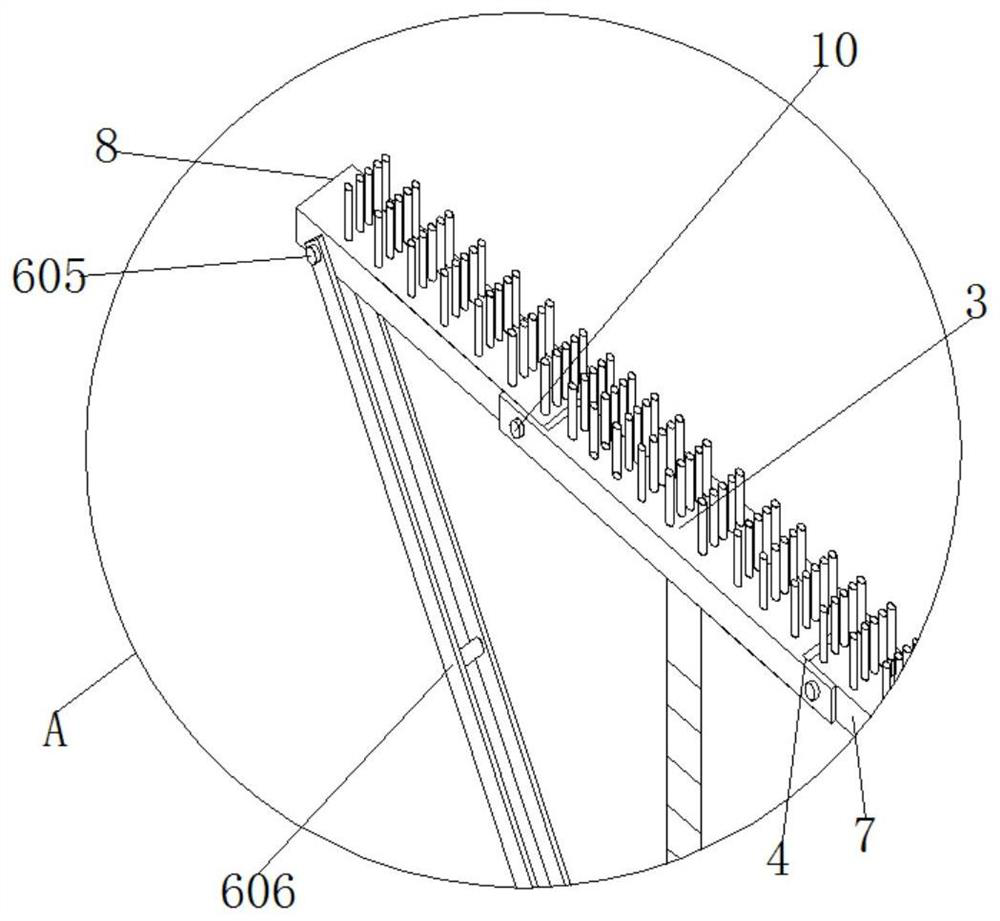

[0036] see figure 1 , 2, 3, 4, 9, 10, a wall painting device for building construction, including a handle and a brush head, the handle includes an upper half rod 2 and a lower half rod 1, an upper half rod 2 and a lower half A rod connection structure 9 is connected between the half rods 1. The brush head is composed of the middle brush head 3, the left brush head 8 and the right brush head 7. The left and right ends of the middle brush head 3 are provided with installation cutouts 4. The side brush head 8 and the right brush head 7 are divided into two installation cutouts 4 inside, and the front of the middle brush head 3 is provided with movable connecting pins 10, and one of the movable connecting pins 10 runs through the middle brush head 3 and the left brush head at the same time. Head 8, another movable connection pin 10 runs through the middle brush head 3 and the right side brush head 7 at the same time, the middle brush head 3 and the left side brush head 8 are art...

Embodiment 2

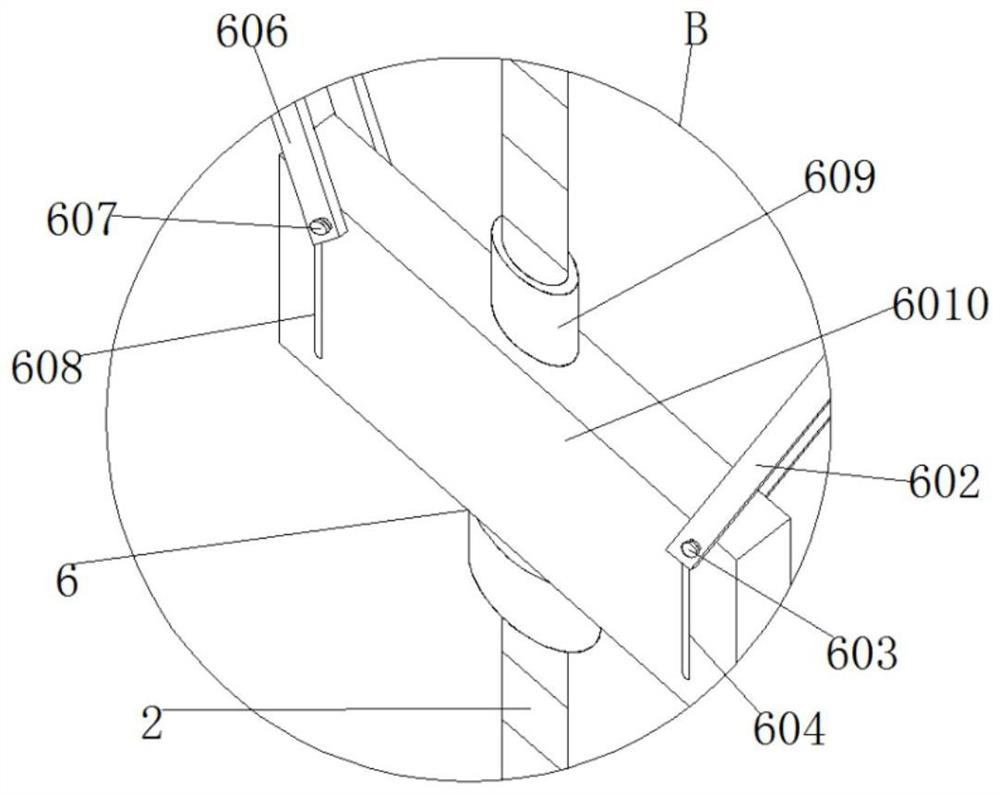

[0040] see figure 1 , 10 , the connecting cylinder 609 is I-shaped, the rectangular movable block 6010 is located in the middle part of the connecting cylinder 609, and the diameter of the inner wall of the rectangular movable block 6010 is smaller than the diameters of the top and bottom of the connecting cylinder 609.

[0041] Through the movable socket of the rectangular movable block 6010 and the connecting cylinder 609, when the connecting cylinder 609 rotates, the function of the rectangular movable block 6010 not turning, thereby avoiding breaking the left connecting rod 606 and the right connecting rod 602.

Embodiment 3

[0043] see figure 1 , 9 , the left connecting piece 607 is the same as the right connecting piece 603, and is composed of a fixed rod 11 and a fastening nut 5, the fixed rod 11 is composed of a stepped cylindrical rod and a threaded surface rod, and the stepped cylindrical rod and the fastening nut 5 Both are T-shaped with an included angle of 180 degrees, and the diameters of the stepped cylindrical rod and the solid part of the fastening nut 5 are the same.

[0044] By rotating the fastening nut 5 in the left connecting piece 607 so that its outer wall close to the rectangular movable block 6010 is located at the outside of the left side through hole 608, then the fixed rod 11 in the left connecting piece 607 is moved to the left side through hole 608 component of the rectangular hole, so that the left brush head 8 and the right brush head 7 are not mirror images of each other in the left and right directions,

[0045] By rotating the fastening nut 5 in the right connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com