Range hood capable of accelerating oil smoke collection and process method

A range hood and oil fume technology, which is applied in the field of kitchen appliances, can solve the problems of limited suction capacity of the exhaust fan, low efficiency of collecting oil fume, and inability to discharge the oil fume, so as to achieve the effects of improving the discharge rate, reducing escape, and accelerating collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following is attached Figure 1-7 The application is described in further detail.

[0050] In order to improve the efficiency of the range hood in collecting oil fume, an embodiment of the present application provides a range hood that accelerates the collection of oil fume.

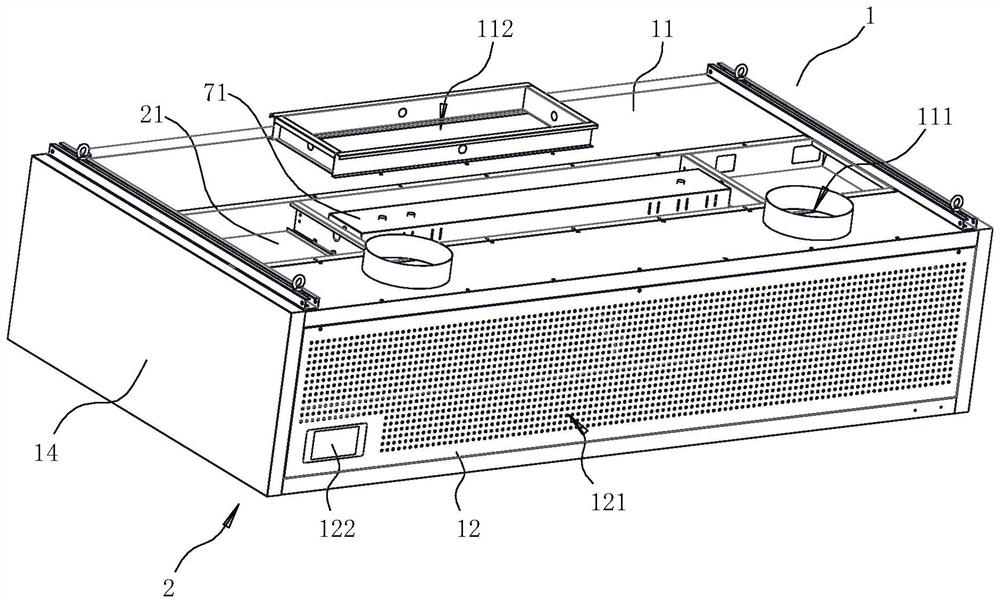

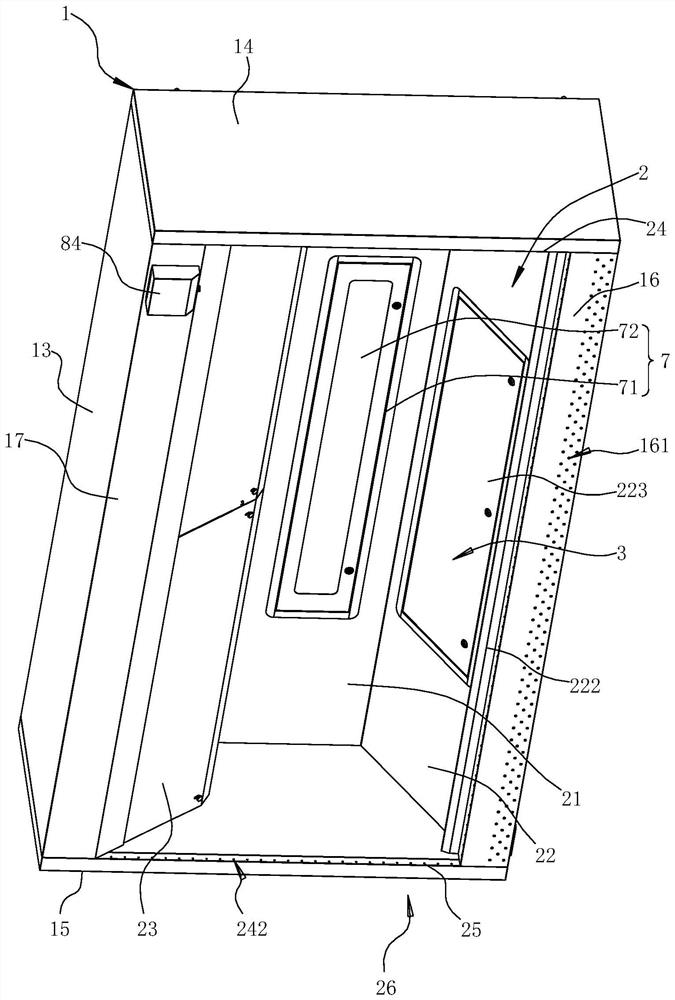

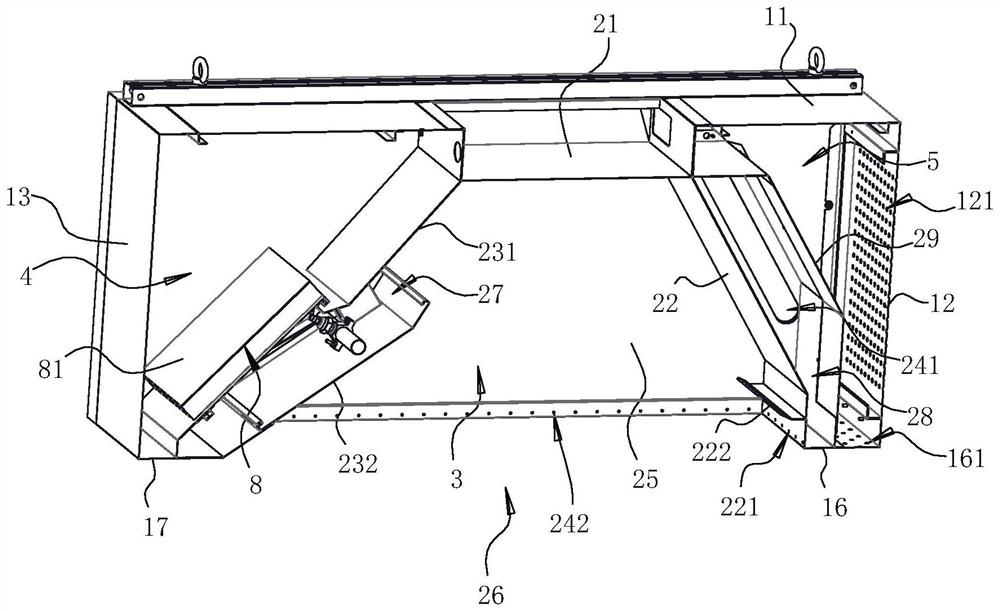

[0051] refer to figure 1 , a range hood for accelerating oil fume collection, comprising a casing 1 and a fume collecting hood 2, and the fume collecting hood 2 is arranged inside the casing 1. The casing 1 is generally arranged as a rectangular box to have length and width. The top of the casing 1 has an upper wall 11, and the upper wall 11 is provided with a supplementary air port 111 for sucking air and an air exhaust port 112 for exhausting oil fumes. The air outlet 112 and the supplementary air outlet 111 are respectively arranged on both sides of the upper wall 11 in the width direction. The air outlet 112 is used for installing an exhaust fan and exhausting oil fumes. The air outlet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com