Intelligent control method of roller kiln, computer equipment and readable storage medium

A technology of intelligent control and roller kiln, which is applied in the fields of intelligent control of roller kiln, computer equipment, and computer-readable storage media, can solve the problems of complex and changeable influencing factors, lag, large time constant, etc., and achieve pertinence and Flexibility, smooth control, and real-time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

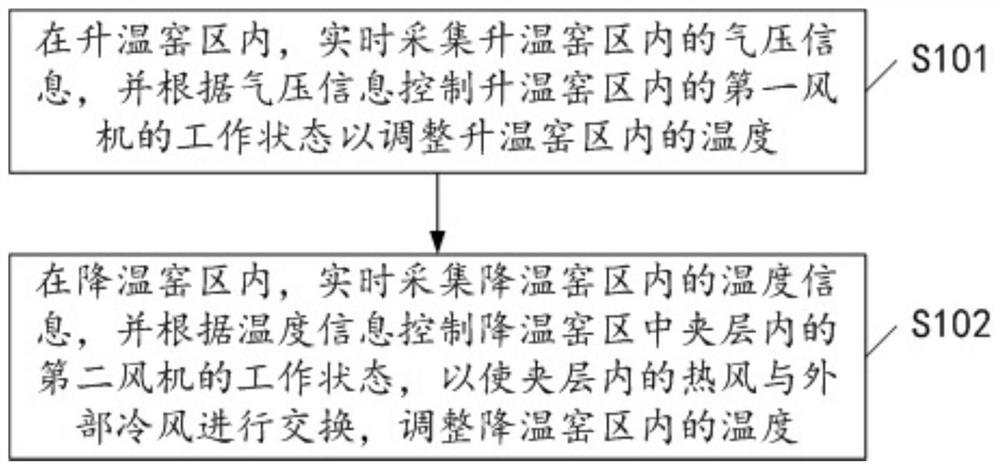

[0025] see figure 1 , figure 1 The flow chart of the first embodiment of the intelligent control method of the roller kiln of the present invention is shown, including:

[0026] S101. In the heating kiln area, collect the air pressure information in the heating kiln area in real time, and control the working state of the first fan in the heating kiln area according to the air pressure information to adjust the temperature in the heating kiln area.

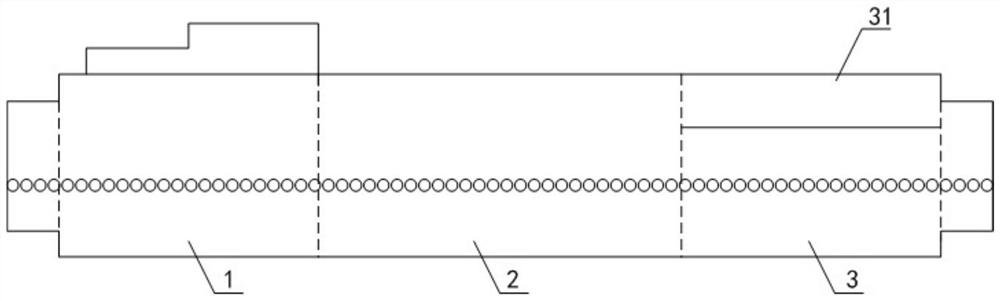

[0027] Such as figure 2 As shown, the roller kiln includes a heating kiln zone 1, a heat preservation kiln zone 2 and a cooling kiln zone 3 connected in sequence. Zone 3 is used to achieve a rapid drop in temperature.

[0028] Specifically, the step of controlling the working state of the first fan in the heating kiln zone 1 to adjust the temperature in the heating kiln zone 1 according to the air pressure information includes:

[0029] (1) Compare the air pressure information with the preset minimum and maximum air pressure. ...

no. 2 example

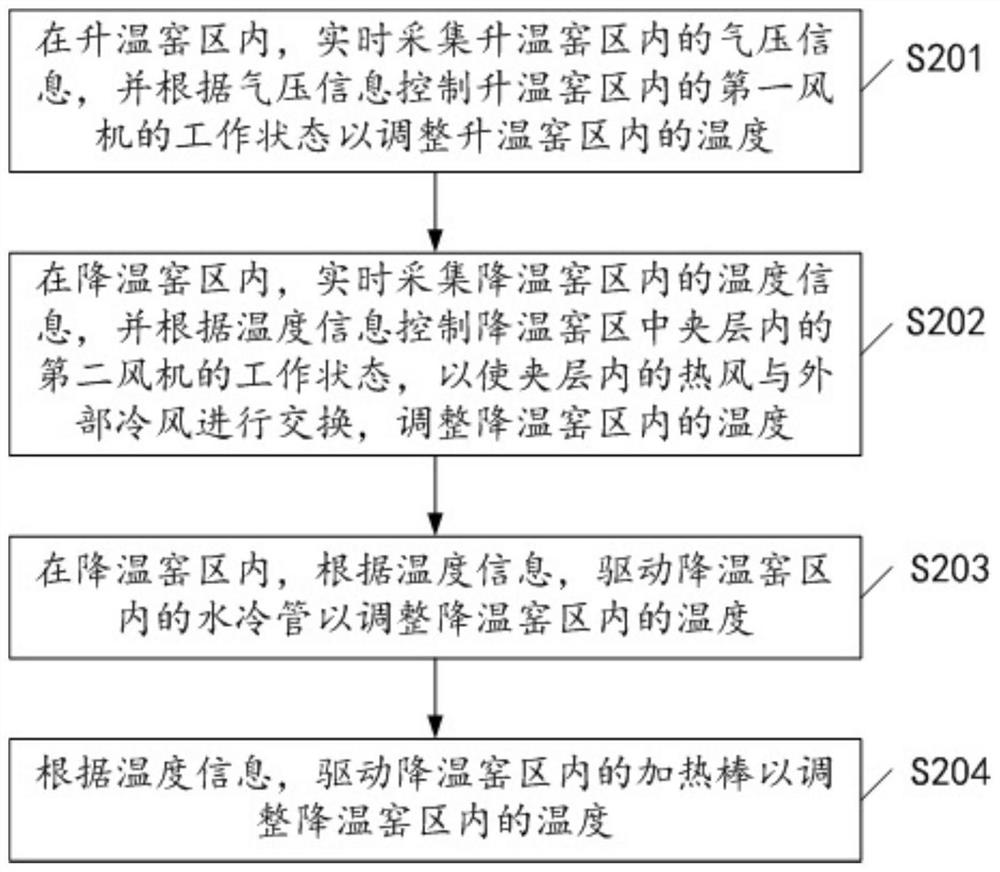

[0049] see image 3 , image 3 Shows the flow chart of the second embodiment of the intelligent control method of the roller kiln of the present invention, including:

[0050] S201. In the temperature-raising kiln area, collect real-time air pressure information in the temperature-raising kiln area, and control the working state of the first fan in the temperature-raising kiln area according to the air pressure information to adjust the temperature in the temperature-raising kiln area.

[0051] S202, in the cooling kiln area, collect temperature information in the cooling kiln area in real time, and control the working state of the second fan in the interlayer in the cooling kiln area according to the temperature information, so that the hot air in the interlayer and the external cold air are exchanged and adjusted Lower the temperature in the kiln zone.

[0052] S203, in the cooling kiln area, according to the temperature information, drive the water cooling pipe in the coo...

no. 3 example

[0057] see Figure 4 , Figure 4 The flow chart of the third embodiment of the intelligent control method of the roller kiln of the present invention is shown, including:

[0058] S301. In the heating kiln area, collect real-time air pressure information in the heating kiln area, and control the working state of the first fan in the heating kiln area according to the air pressure information to adjust the temperature in the heating kiln area.

[0059] S302, in the cooling kiln area, collect the temperature information in the cooling kiln area in real time, and control the working state of the second fan in the interlayer in the cooling kiln area according to the temperature information, so that the hot air in the interlayer and the external cold air are exchanged and adjusted Lower the temperature in the kiln zone.

[0060] S303, in the cooling kiln area, according to the temperature information, drive the water cooling pipe in the cooling kiln area to adjust the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com