A device and method for measuring the overall three-dimensional profile of the inner surface of a concave workpiece

A technology of three-dimensional profile and measuring device, which is applied in the field of profile measurement, can solve problems such as complex system structure and insufficient adaptability of a single probe angle, and achieve the effect of avoiding speckle phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

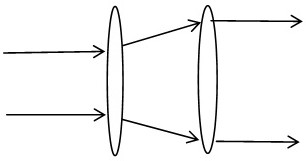

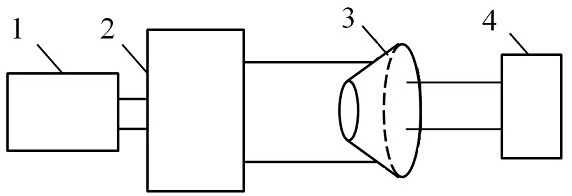

[0041] A device for measuring the overall three-dimensional contour of the inner surface of a concave workpiece, such as figure 1 shown, including:

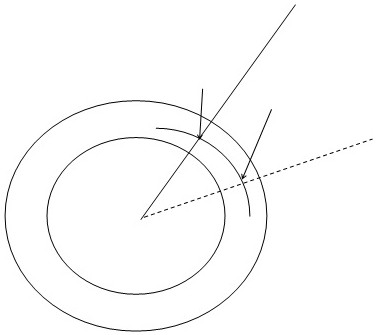

[0042] The light generation module is used to generate ring light and collimated light at the same time, and the transmission direction of the ring light is perpendicular to the central axis of symmetry of the tested sample 11, and the transmission direction of the collimated light is parallel to the central axis of symmetry of the tested sample 11 . With this arrangement, the central axis of the light generating module (which is also the center of the ring light) and the symmetrical central axis of the sample 11 to be tested can only be parallel but not coaxial, that is, the circular error caused by the off-axis of the ring light will not be caused (from a perfect circle to an ellipse), avoiding the problem of adding a coaxial adjustment mechanism to the system when the annular light is obliquely incident (when the angle betwee...

Embodiment 2

[0064] The present embodiment provides a method for measuring the overall three-dimensional contour of the inner surface of a concave workpiece, which is applied to the device for measuring the overall three-dimensional contour of the inner surface of a concave workpiece as provided in Embodiment 1, including the following steps:

[0065] obtain the first reflected light set;

[0066] obtain the second reflected light set;

[0067] Obtain the profile of the side surface of the concave space according to the first reflected light set and the annular light section method;

[0068] Obtain the contour of the inner bottom surface according to the second reflected light set and the laser triangulation method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com