Quantum dot diffusion film for Mini Led module and preparation method

A quantum dot and diffusion film technology, applied in the field of quantum dot diffusion film and preparation of MiniLed modules, can solve the problems of affecting the popularization and use, the high price of quantum dots, and the high price of products, so as to avoid glare problems, improve brightness, The effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

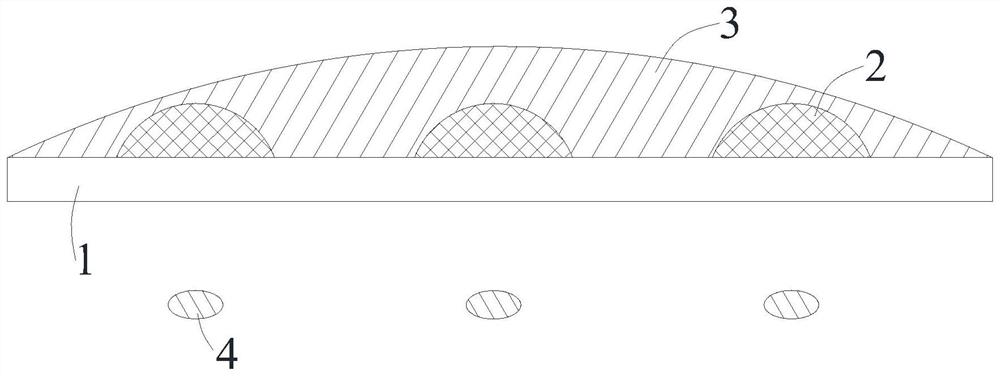

[0020] In yet another aspect, the present invention also provides a method for preparing a quantum dot diffusion film for Mini Led modules, comprising the following steps: after mixing acrylic resin, red quantum dots, green quantum dots and first scattering particles, preparing Get the quantum dot spinning solution; adjust the spinning head of the spinning machine to correspond to the position of the lamp bead, add the quantum dot spinning solution into the spinning machine for spinning to form a quantum dot spinning line, and control the stroke of the spinning head so that The width of each layer of spinning area is continuously reduced, so that the quantum dot spinning line is stacked layer by layer on the surface of the substrate layer and cured by UV to form a hemispherical quantum dot light conversion area; the acrylic resin and the second scattering particles After mixing, a diffusion liquid is obtained; after the diffusion liquid is fed into a spinning machine for spinni...

Embodiment 1

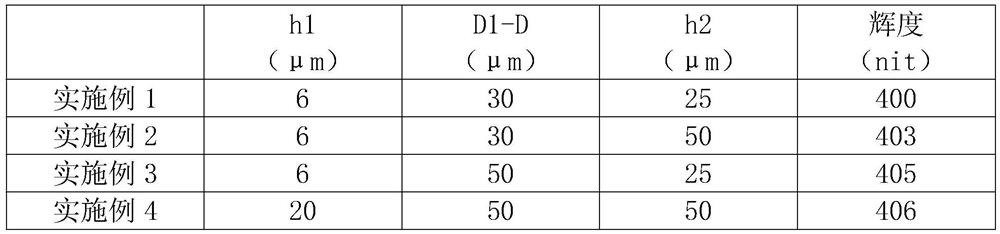

[0030] First, fully mix acrylic resin, red quantum dots, green quantum dots and first scattering particles according to the ratio of 100:3:5:6 to form a quantum dot spinning solution, inject it into the glue barrel of the spinning machine, and set the spinning Spinning starts after the machine spinning position and spinning activity range parameters are set. The quantum dot spinning solution passes through the spinning head to form a spinning thread on the substrate layer 1. The spinning thread is piled up layer by layer according to the program setting, and undergoes continuous UV Solidify to form a quantum dot light conversion area; the spinning machine sets the position of the spinning head to the corresponding position of each Mini LED, and the width of each layer of spinning area is continuously reduced to form a quantum dot light conversion covering each mini LED lamp bead A semi-finished product was prepared in the region; wherein, the particle size of the first scatteri...

Embodiment 2

[0033] First, fully mix acrylic resin, red quantum dots, green quantum dots and first scattering particles at a ratio of 100:1:7:4 to form a quantum dot spinning solution, inject it into the glue barrel of the spinning machine, and set the spinning Spinning starts after the machine spinning position and spinning activity range parameters are set. The quantum dot spinning solution passes through the spinning head to form a spinning thread on the substrate layer 1. The spinning thread is piled up layer by layer according to the program setting, and undergoes continuous UV Solidify to form a quantum dot light conversion area; the spinning machine sets the position of the spinning head to the corresponding position of each Mini LED, and the width of each layer of spinning area is continuously reduced to form a quantum dot light conversion covering each mini LED lamp bead A semi-finished product was prepared in the region; wherein, the particle size of the first scattering particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com