Photoresist, display panel and manufacturing method of display panel

A technology of photoresist and substrate, which is applied in the photoplate-making process of the patterned surface, photosensitive materials used in optomechanical equipment, optics, etc., can solve problems such as the loss of brightness of the retaining wall, so as to improve brightness and light utilization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

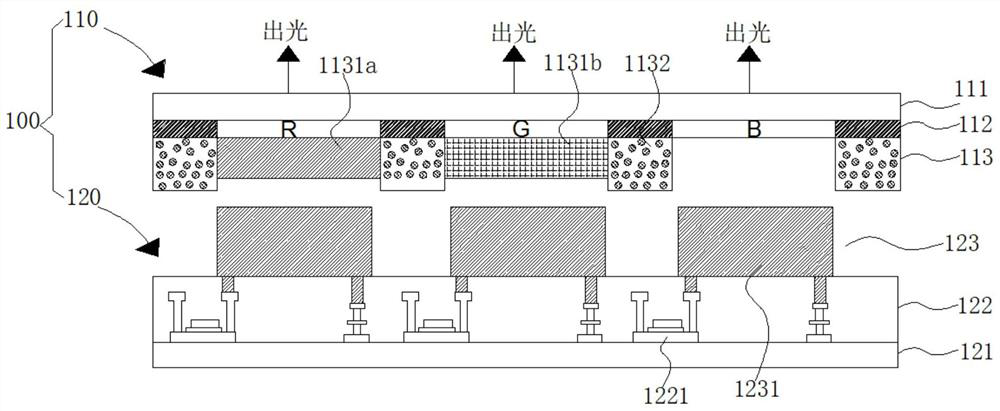

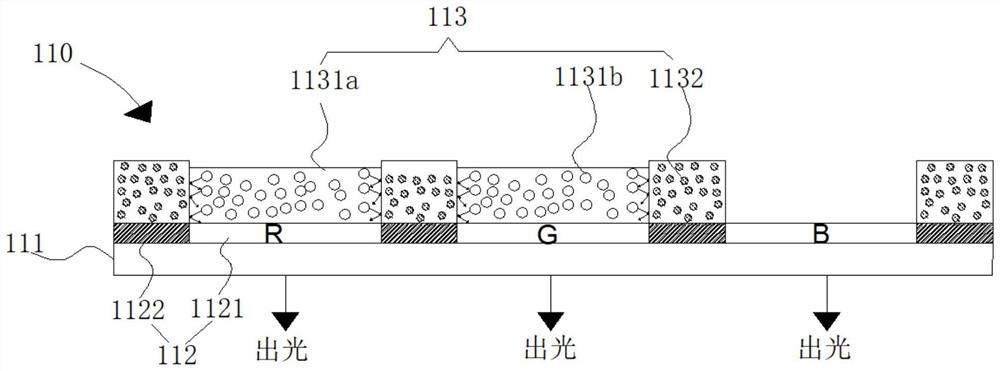

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by those skilled in the art without making creative efforts belong to the protection scope of the present invention.

[0038] The photoresist provided by the present invention introduces highly reflective metal balls into the transparent colloid, thereby endowing the transparent colloid with light reflection properties, because the reflectivity of the metal balls is much higher than that of commonly used reflective materials, such as scattering particles such as titanium dioxide Therefore, the photoresist has strong light reflection ability, and can reflect rather than absorb the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com