Cable peeling device and cable peeling method

A technology for cables and detection devices, which is applied in the field of cable peeling devices, and can solve problems such as inaccuracy and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

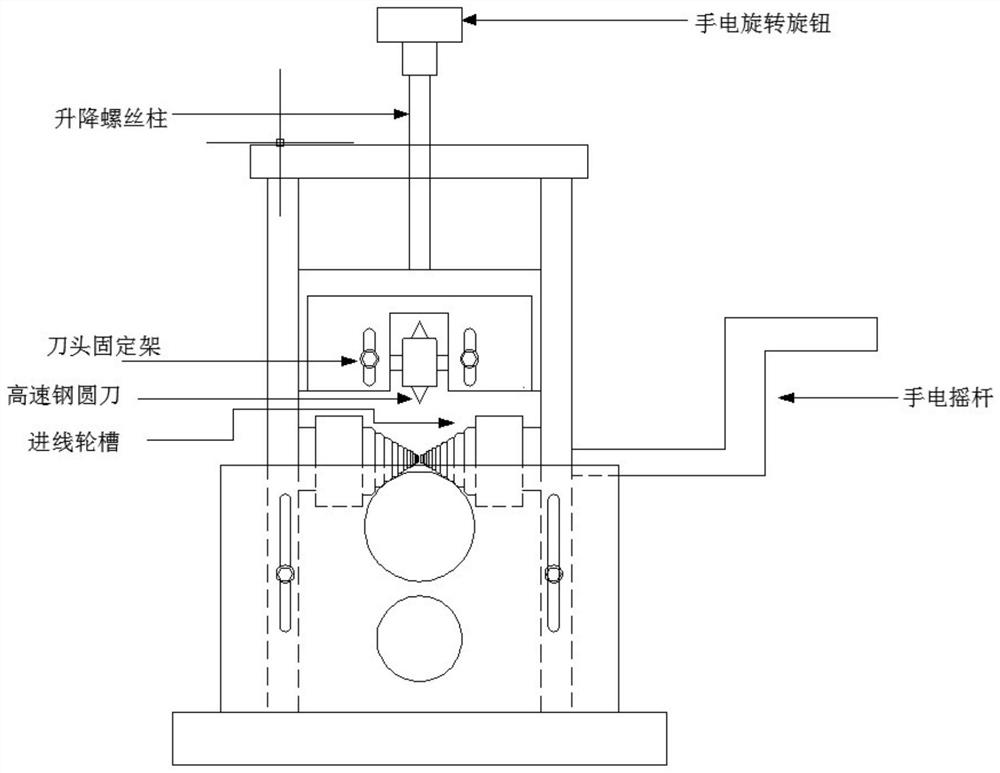

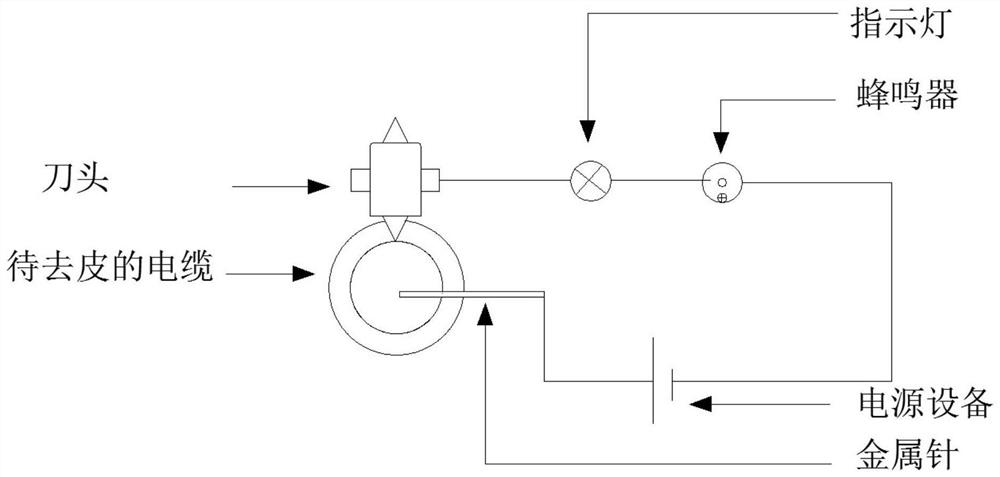

[0030] The present invention provides a cable peeling apparatus, a schematic diagram image 3 Distance

[0031] Includes cutters, indicators, buzzers and metal needles. One-end cutter head of the circuit and buzzer, the other end of the circuit connects a metal needle, insert the metal needle into the cable to be peeled to peeled, when the cutter is in the process of degeneration, the conductor of the cable, The entire circuit is turned on, the indicator is on, the buzzer issues an alarm sound, the relative movement of the cutter head and the conductor is immediately stopped, or the tip height is automatically adjusted, thereby avoiding the injury of the tool head to the conductor. When the head is adjusted to a safe distance from the distance from the conductor, the indicator and buzzer are not turned on, and the peeling device continues to work. The conductor of the cable is detected by a metal needle to control or adjust the peeling operation of the cutter head.

[0032] The adv...

no. 2 Embodiment

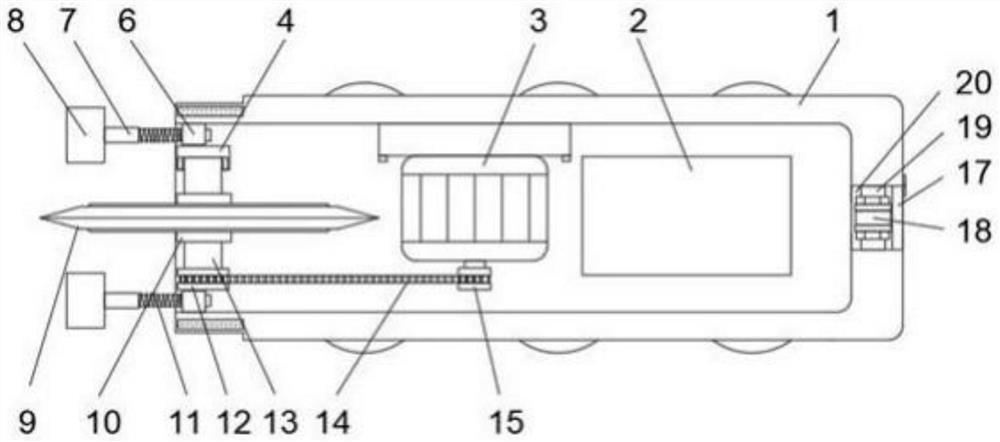

[0034] The present invention also provides a cable peeling apparatus, a schematic diagram Figure 4 Distance

[0035]Includes a cutter head, an eddy current sensor, an adjustment button, a single chip, a display. In order to prevent the tutoon in advance, the eddy current sensor probe can be installed in the head position, referred to as the eddy current sensor. The vortex flow sensor can be static or dynamically non-contact, high linearity, and high resolution measuring the distance from the surface of the probe. There is an advantage of long-term working stability, strong anti-interference ability, and response speed. It is very suitable for measuring the relative position of the tool head and the cable conductor when the cable is removed. Since the principle of the electric turbine sensor is to provide an alternating current to the coil in the probe, a magnetic field is formed around the sensor coil, and the conductor will be placed in this magnetic field, and the electrot can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com