Offshore wind power scour pit self-repairing device with micro-ecological breeding function

An offshore wind power and self-repairing technology, which is applied in fish farming, seaweed cultivation, horticulture, etc., can solve the problems of single-function farming devices and poor environmental protection effects, and achieve self-repairing, reduce farming costs, and increase stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

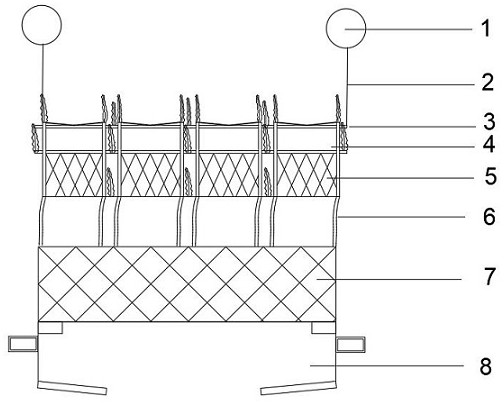

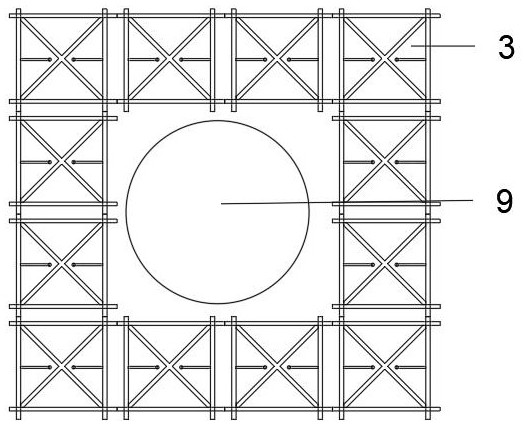

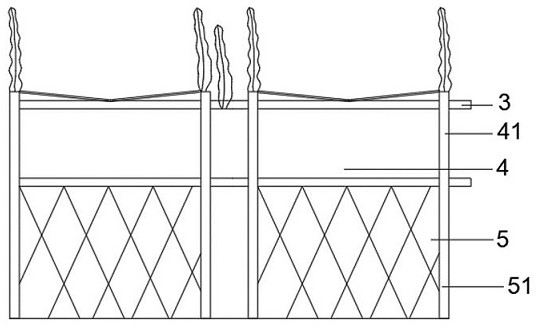

[0043] Such as figure 1 , 7 As shown, the upper catch culture device may not completely cover the scour pit. The silt chamber 4 is arranged around the pile foundation 9, and twelve silt chambers 4 are arranged in a circle, and the twelve silt chambers 4 are square and ring-shaped when viewed from above. A certain gap is reserved between every two silt chambers 4, and the silt chambers 4 can be connected by rigid connectors. The cage room 5 is a square ring consistent with the square ring of the sediment chamber 4. The cross-section of net cage cage 7 is square annular, and shape and size are identical with net cage room 5, and are integral structures. The mud storage chamber 8 is a square tube, and the top opening is square, and the top opening size is consistent with the cross-sectional edge size of the net cage cage 7.

Embodiment 2

[0045] Such as Figure 8 As shown, the upper catchment culture device covers the upper part of the scour pit, while the distribution area of the lower mud storage device is smaller than that of the upper catchment culture device; the sediment from the upper catchment culture device does not completely fall into the mud storage Room 8. The silt chamber 4 is arranged around the pile foundation 9, and ninety-six silt chambers 4 are arranged in a week, and the ninety-six silt chambers 4 are square ring-shaped when viewed from above. A certain gap is reserved between every two silt chambers 4, and the silt chambers 4 can be connected by rigid connectors. The cage room 5 is a square ring consistent with the square ring of the sediment chamber 4. Net cage cage 7 is integral structure, and net cage cage 7 cross sections are square ring, and net cage cage 7 cross sections are less than the cross section of net cage room 5. The mud storage chamber 8 is a square tube, and the top op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com