Boiler biomass transportation device

A transportation device, biomass technology, applied in grain processing, solid separation, sieving, etc., can solve the problem of not having biomass fuel pulverization and sieving, and achieve the effect of saving steps and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

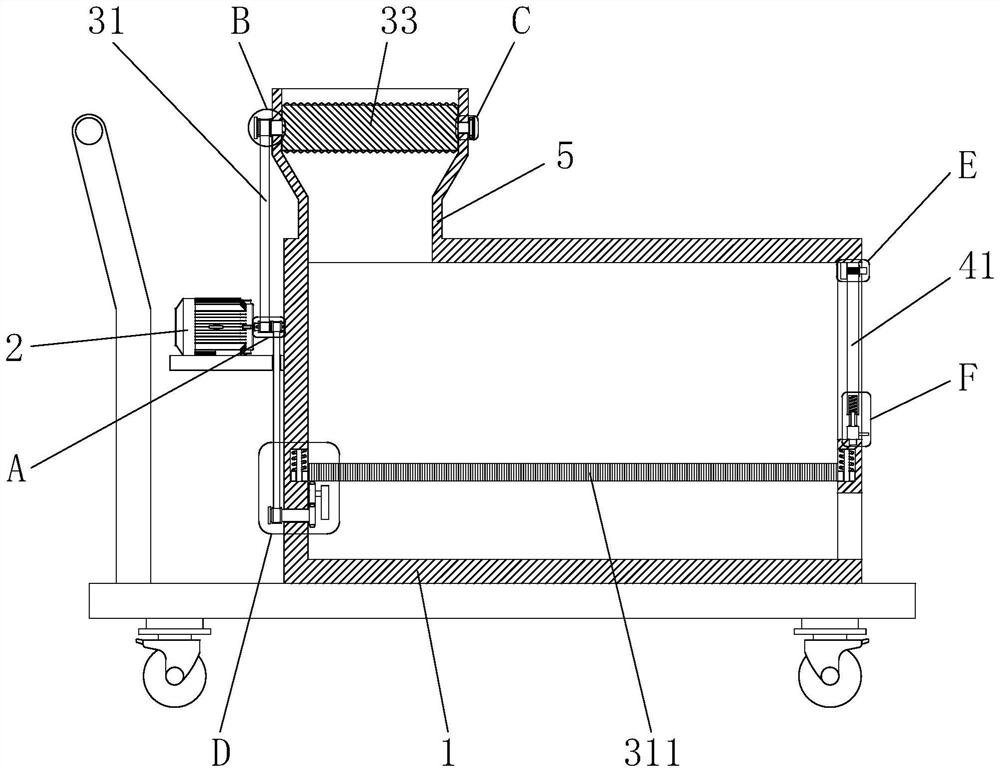

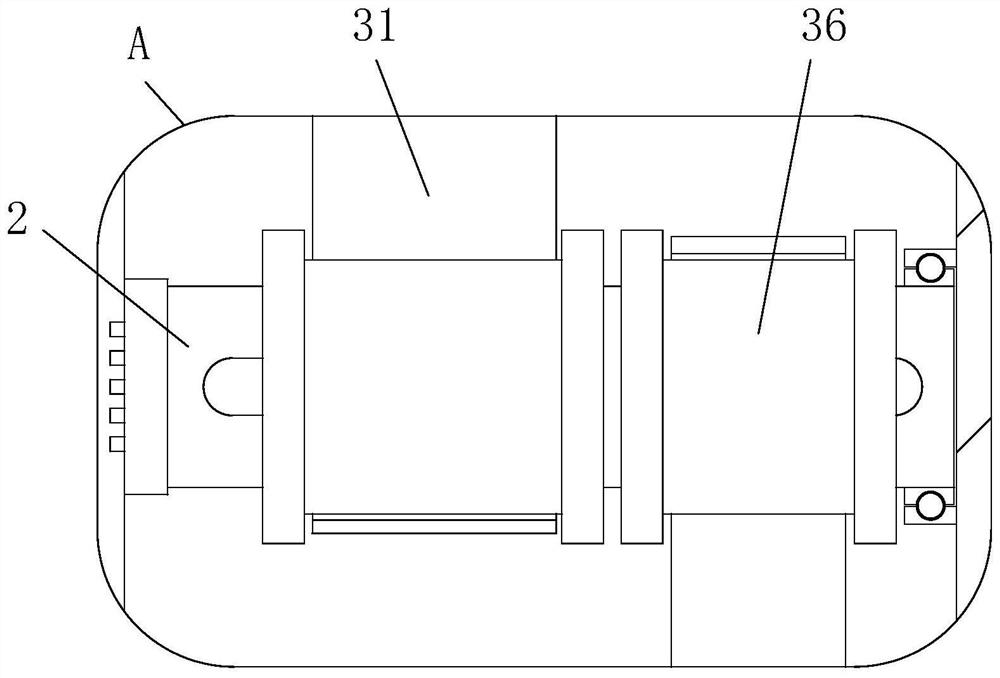

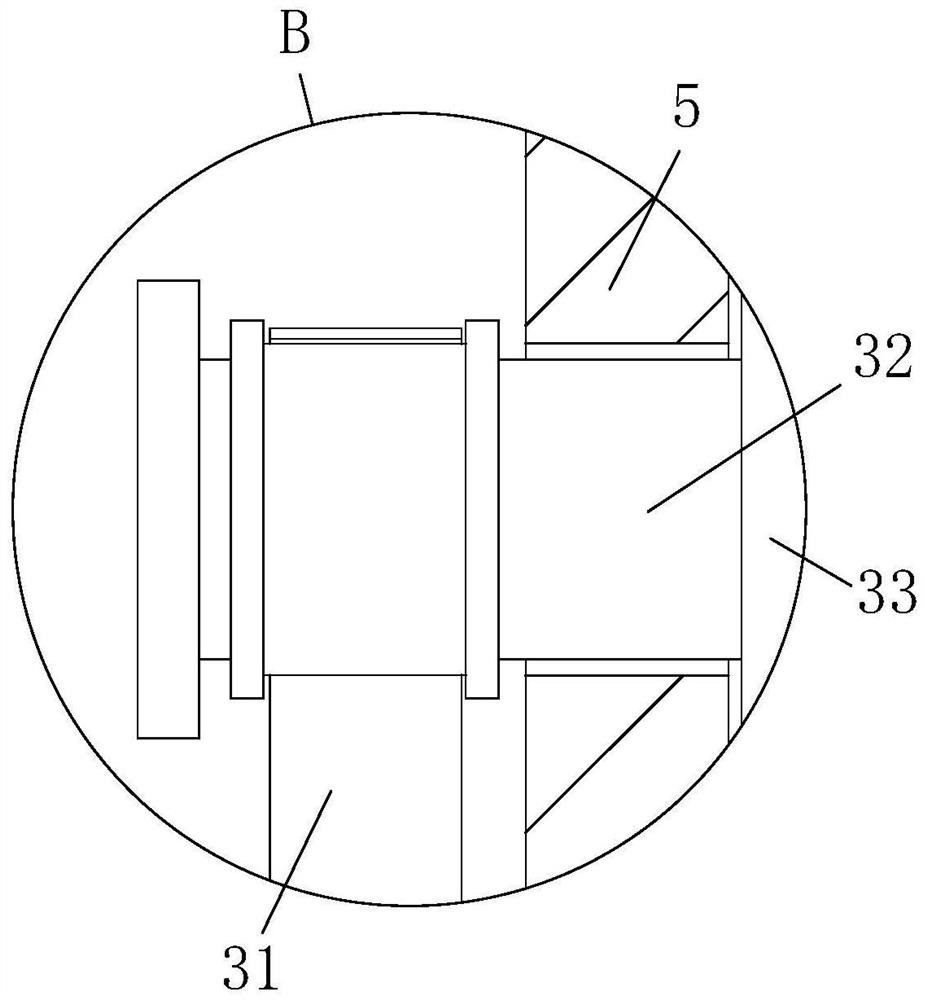

[0030] See Figure 1-9 As shown, a boiler biomass transport device, including the device main body 1, the motor 2, and the feed port 5; one side of the apparatus main body 1 is provided with a motor 2, and the feed port 5 is opened on one side of the tip end of the apparatus main body 1. The device main body 1 is provided with a pulverized screening mechanism; the pulverized screening mechanism includes a first transmission belt 31, a connecting shaft 32, a broken roller 33, an active gear 34, a driven gear 35, a second drive belt 36, The transmission shaft 37, the rotating gear 38, the passive gear 39, and the screening assembly are arranged on the output shaft of the motor 2, and the other end of the first transmission belt 31 is disposed at the connecting shaft 32. On the outside, the connecting shaft 32 penetrates through the crushing roller 33, and the crushing roller 33 is provided with two sets, the active gear 34 and the connecting shaft 32 fixedly connected to one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com