Film pasting equipment

A film sticking equipment and film sticking technology, which is applied in the field of workpiece film sticking, can solve problems affecting film sticking efficiency, etc., achieve the effects of improving film sticking efficiency and product yield, realizing fully automated operation, and improving film sticking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0065] An embodiment of the present invention provides a film sticking device, which will be described in detail below with reference to the accompanying drawings. For simplicity, only those elements relevant to the subject matter of the text are shown. The overall vacuum suction assembly can have many other configurations and many other types of equipment can be used.

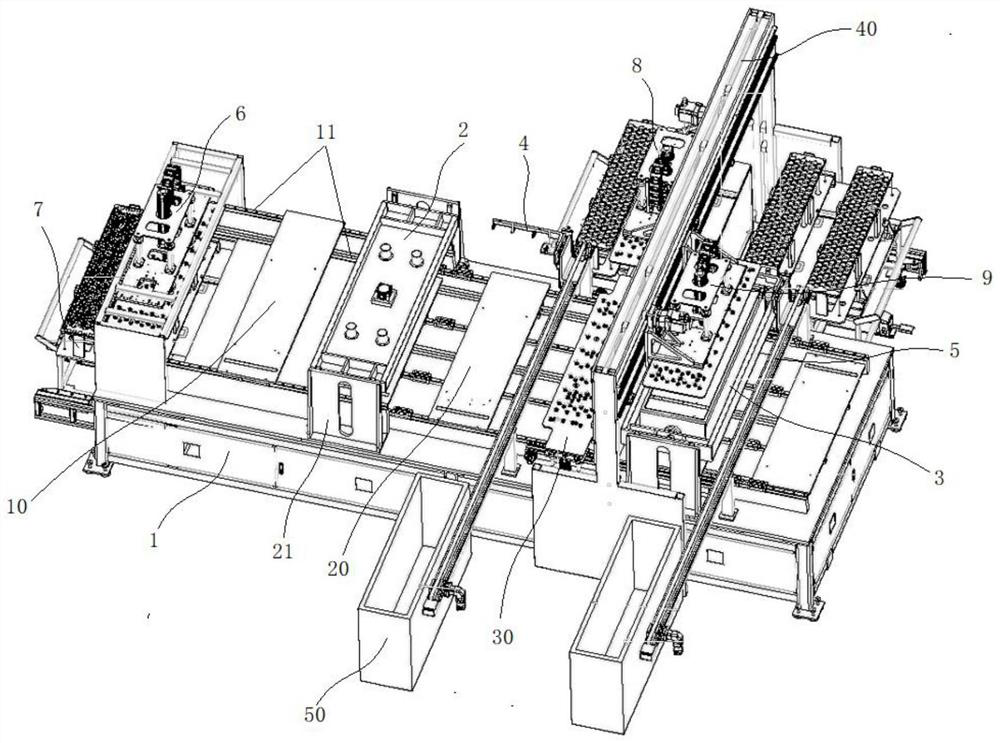

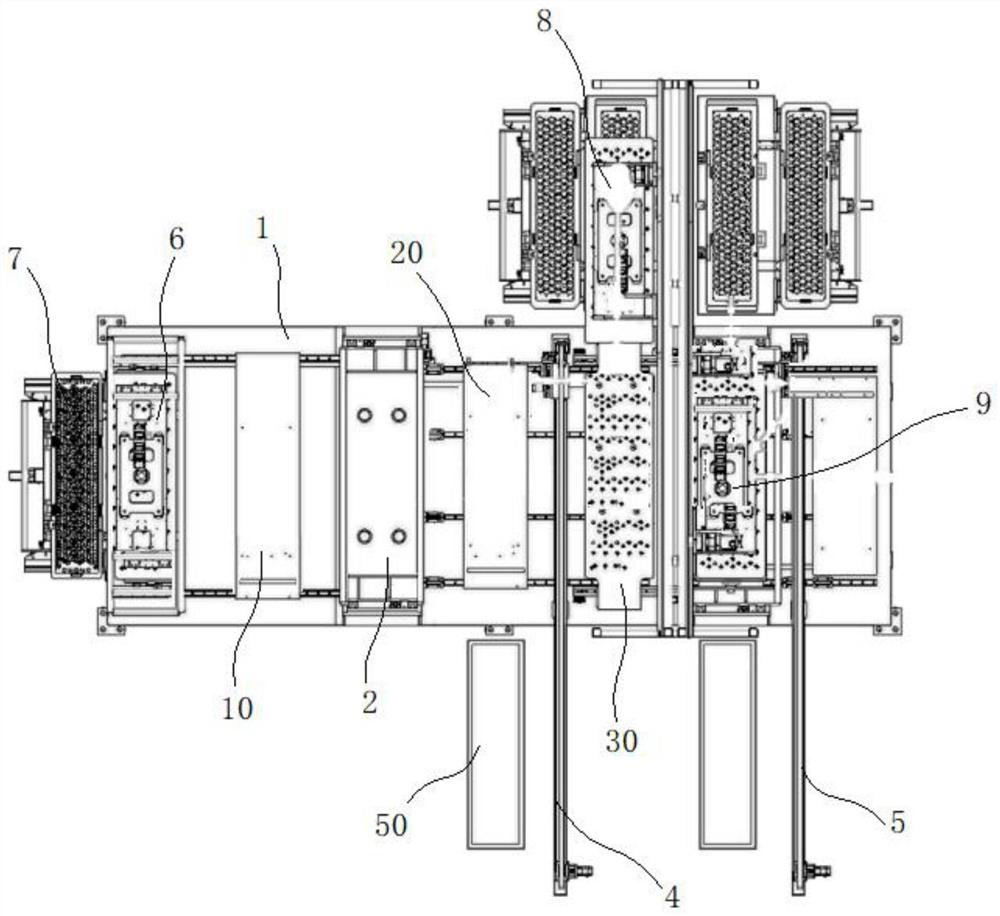

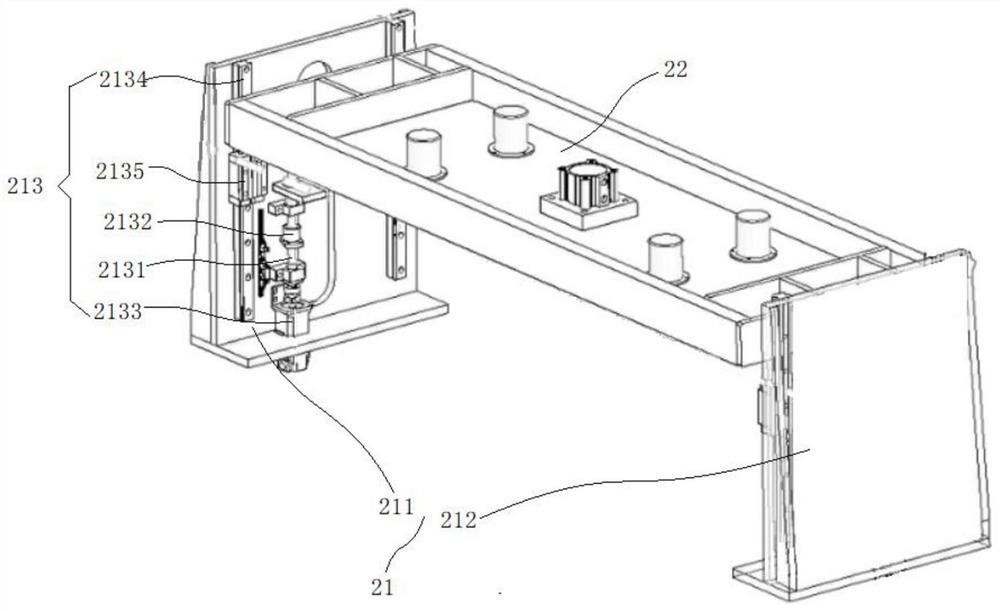

[0066] Specifically, such as figure 1 and figure 2 As shown, the film sticking equipment includes a base 1, a first film sticking device 2, a second film sticking device 3, a transplanting device 20 and a transfer device 30;

[0067] There are multiple groups of transmission channels 11 arranged on the base 1, and two adjacent groups of transmission channels 11 are arranged up and down;

[0068] The first film sticking device 2 is supported on the base 1, and the first film sticking device 2 is used to pick and place the workpiece to be filmed, and the workpiece to be filmed includes a first bonding surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com