Automatic carton packaging assembly line

An automatic packaging and assembly line technology, applied in packaging, transportation, packaging, papermaking, etc., can solve the problems of unable to meet the production needs of enterprises, unable to form packaging lines, and low production efficiency, so as to achieve rapid batch production and good economic use value , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

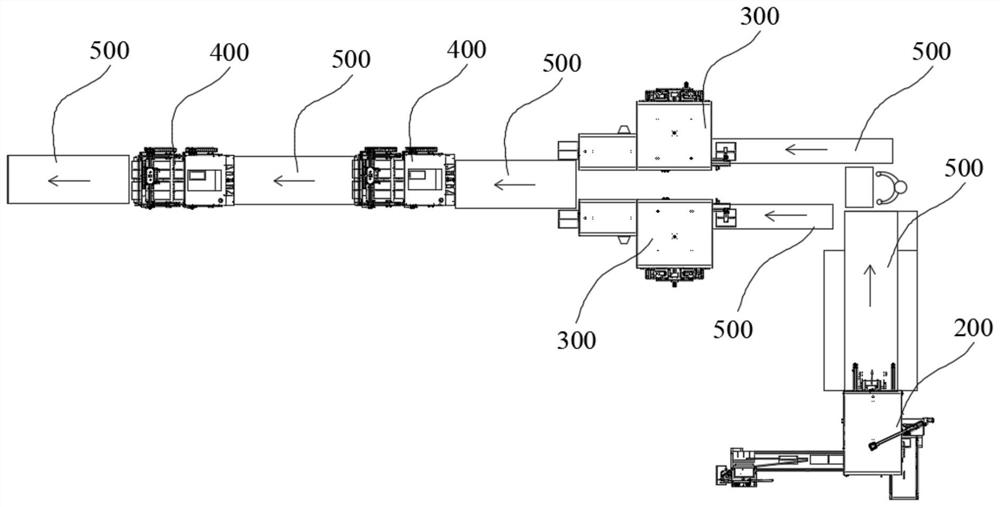

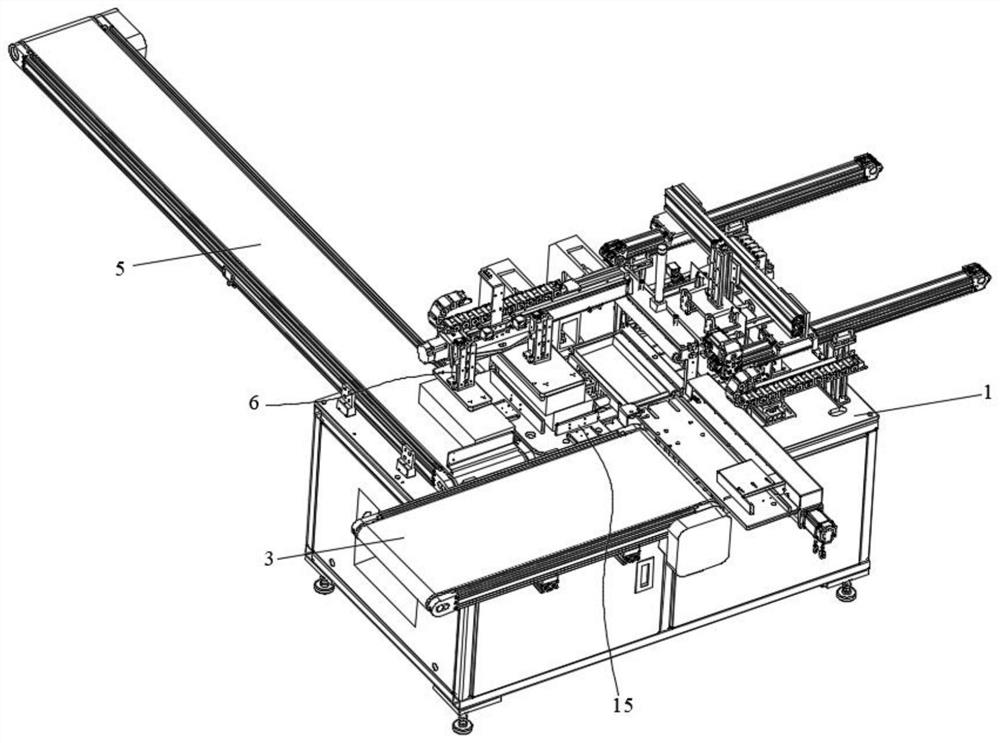

[0112] Such as Figure 1 to Figure 44 As shown, a carton automatic packaging line of the present invention is used for the packaging of heaven and earth boxes. The sky and earth boxes 2-3 include a sky cover 2 and a ground cover 4, and the assembly line includes:

[0113] Combining device 200, used for bonding and assembling an outer connection surface of the sky cover 2 and the ground cover 4;

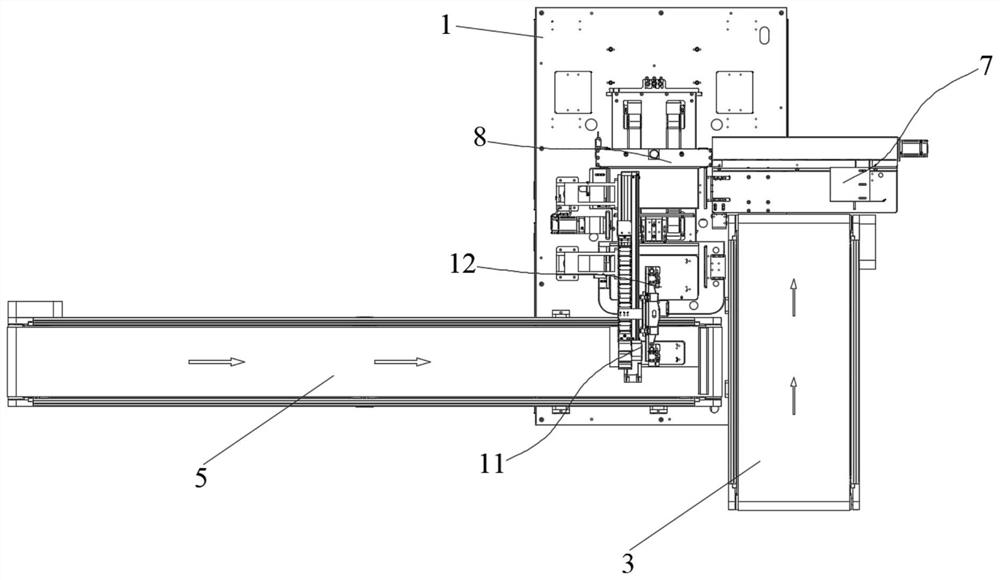

[0114] The lining device 300 is arranged on the last station of the combination device 200. The lining device 300 includes a glue mechanism for pasting the lining paper in the heaven and earth box 2-3; the lining paper processing mechanism is located at the bottom of the glue mechanism. The latter station is used to flatten, foam and scrape the lining paper pasted in Tiandi Box 2-3;

[0115] The dispensing device 400 is arranged on the next station of the lining device 300, and is used for dispensing the inside of the ground cover 4;

[0116] The combination device 200, the lining d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com