Precise control system, method and device for leather making process

A control system and control device technology, applied in the field of tanning, can solve the problems of material error, unstable product quality, and inability to achieve accurate feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

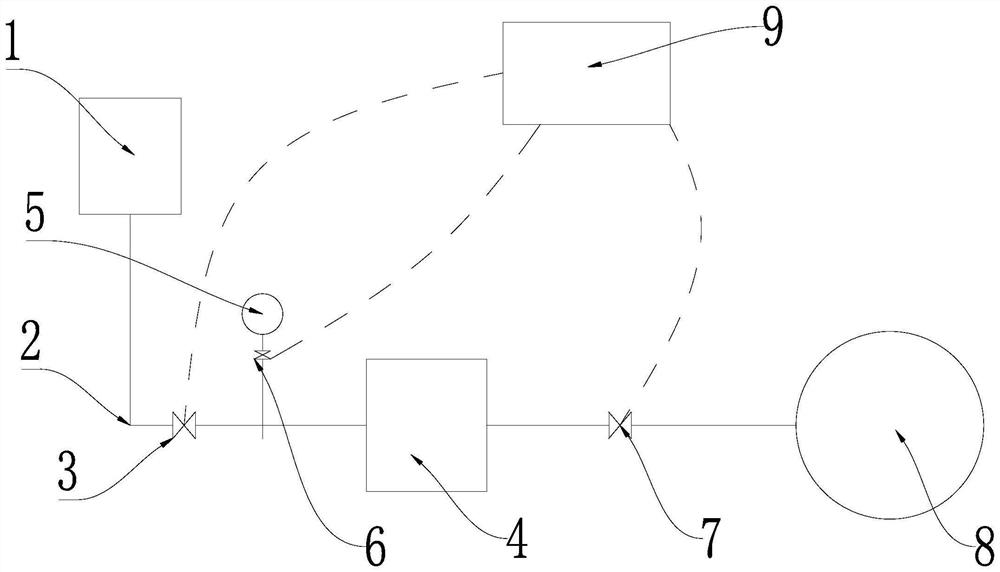

[0031] See figure 1 The main body of the present embodiment is a precision control system for the leather process comprising a drum 8 for leather processing, and a feed drum 8 is provided, the feed device comprising a control device 9, a storage The can 1 and the metering device 4, the tank 1, the metering device 4, and the drum 8 are in communication with the tube 2, and the tank 1 is used to store the feedstock, and the tube 2 is used to deliver the storage. The raw material in the can 1 is passed through the meter 4 to the drum 8, and the meter 4 is used to measure the feedstock input to the drum 8, the control device 9 for the meter. Device 4 and the drum 8 are remotely controlled. The original manual feeding is changed to the automatic control system, and the feed amount can be accurately controlled by the metering device 4 according to the process requirements, automatic ingredients and feed. It is possible to accurately adjust the rotation speed and rotation of the drum 8, ...

Embodiment 2

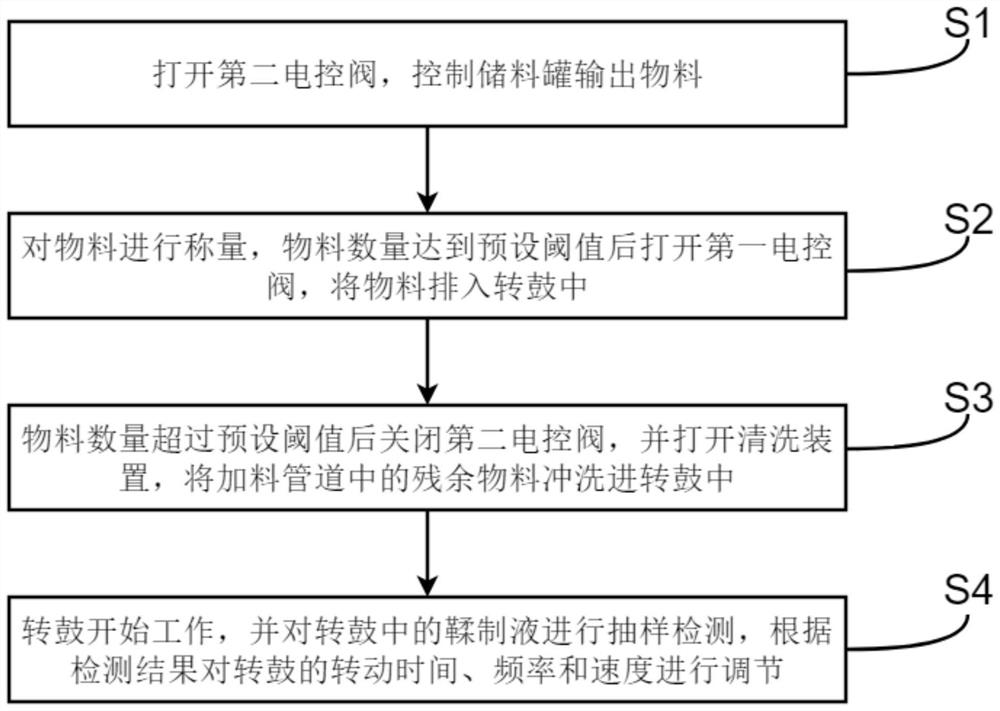

[0040] See figure 2 This embodiment also provides a precision control method for the leather process, applied to the above-mentioned feeding system, including the following steps:

[0041] S1: Open the second electrical control valve 3, control the storage tank 1 to output the material;

[0042] S2: Measure the material, the number of materials reaches the preset threshold, open the first electric control valve 7, and discharge the material into the drum 8;

[0043] S3: The second electrical control valve 3 is closed after the number of materials exceeds the preset threshold, and the cleaning device 5 is opened, and the residual material in the tube 2 is flush into the drum 8.

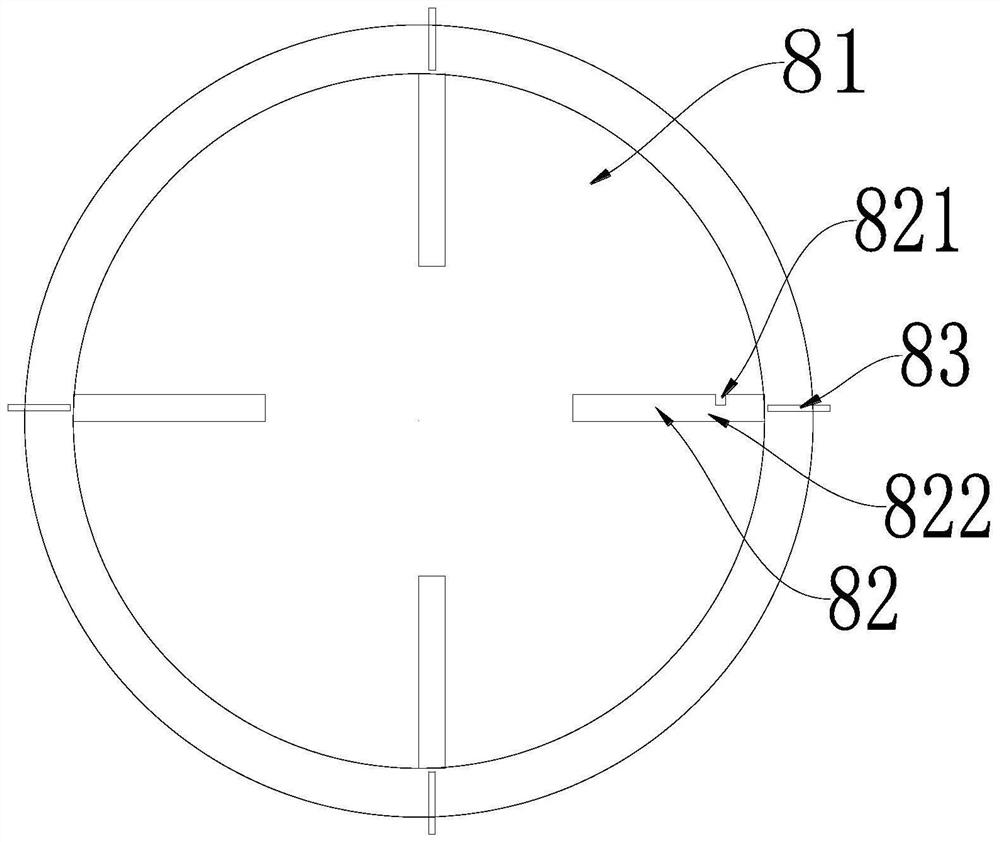

[0044] See image 3 A precision control device for the leather process is applied to the above-described control system, including a drum 8 for leather processing, the drum comprising a rotating tank 81, and the rotating cabin 81 is provided with a feeding hopper And a control box for accommodating a contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com