Motor and vehicle

A stator slot and flat wire winding technology, applied in the shape/style/structure of the winding conductor, can solve the problems of reduced motor performance, large back electromotive force harmonics, motor torque fluctuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The terms used in the embodiments of the present application are only used to explain specific embodiments of the present application, and are not intended to limit the present application.

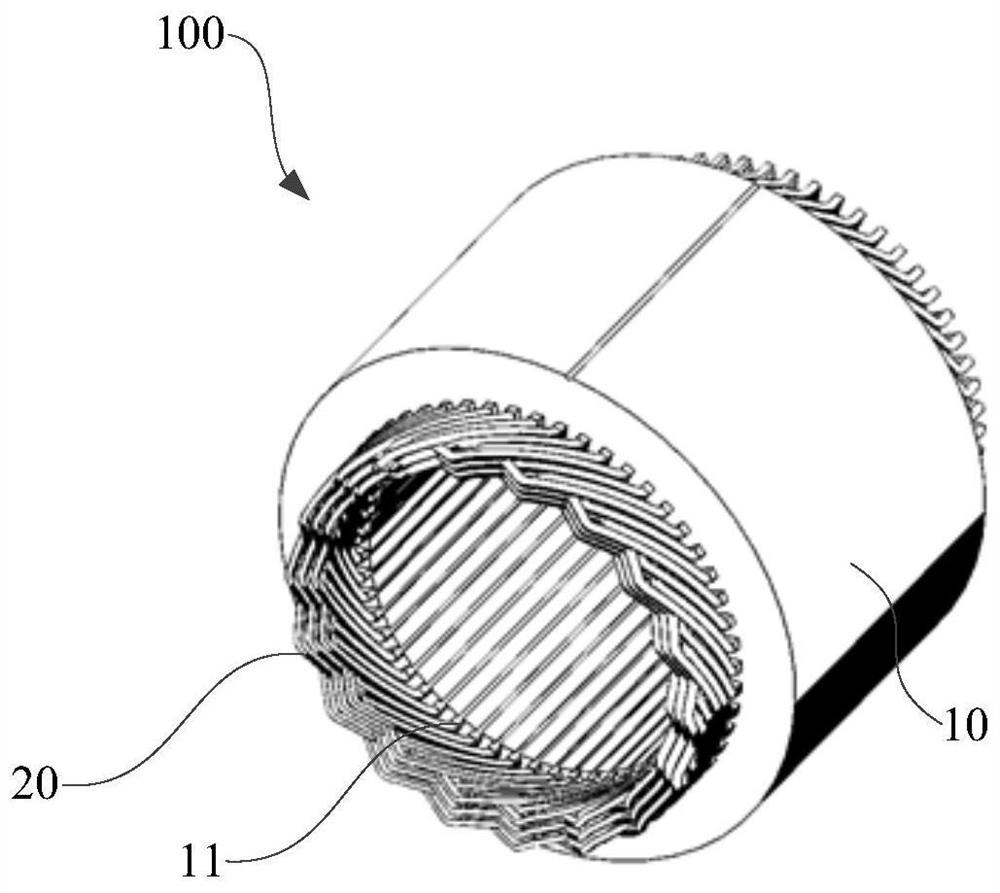

[0057] The motor usually includes a stator core and a stator winding wound on the stator core. Specifically, the stator core is usually provided with a plurality of stator slots, and the plurality of stator slots are arranged at intervals along the circumference of the stator core. The stator slots The extension direction of the stator core can be parallel to the axial direction. The stator slot can play the role of limiting and fixing, and the stator winding can be wound on the stator core through the stator slot.

[0058] Among them, some terms in the motor are explained:

[0059] The number of poles (p) of the motor is the number of magnetic poles of the motor. The magnetic poles are divided into N poles and S poles. Generally, one N pole and one S pole are called a pair of mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com