Flexible circuit board placement station scraping mechanism

A flexible circuit board and station technology, which is applied in the directions of printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems that the flexible circuit board is difficult to straighten and the processing position is not correct, and is conducive to accurate adsorption and increased adhesion. , the effect of increased adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the technical solution of the present invention more clearly and completely, the present invention will be further described below in conjunction with the accompanying drawings.

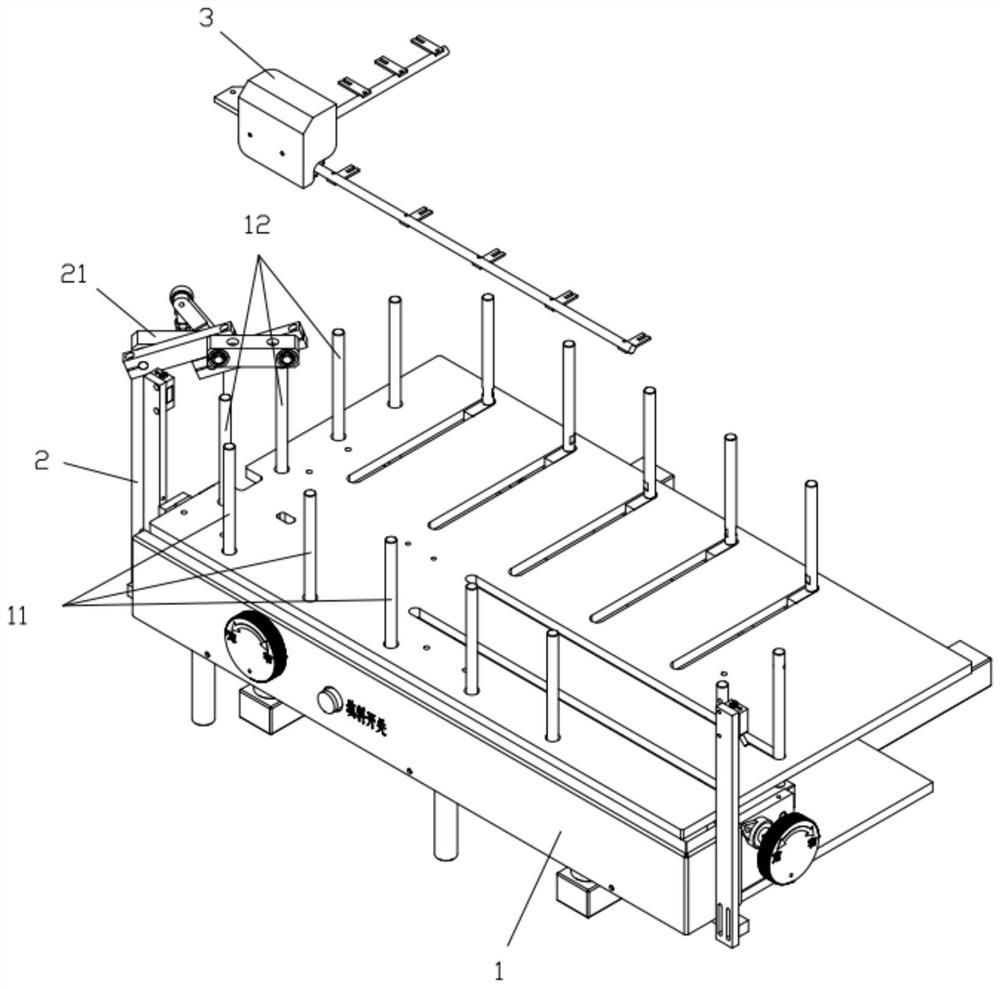

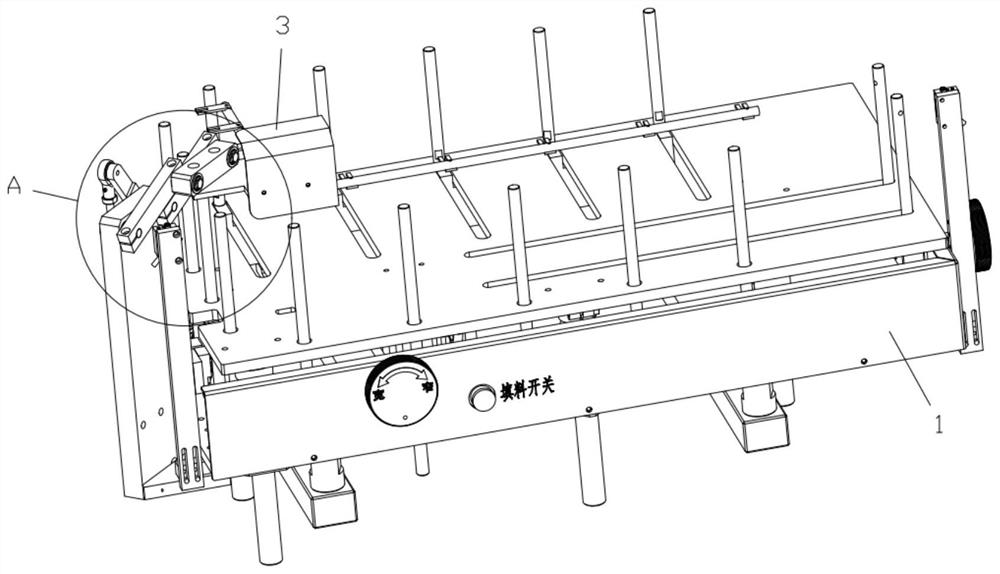

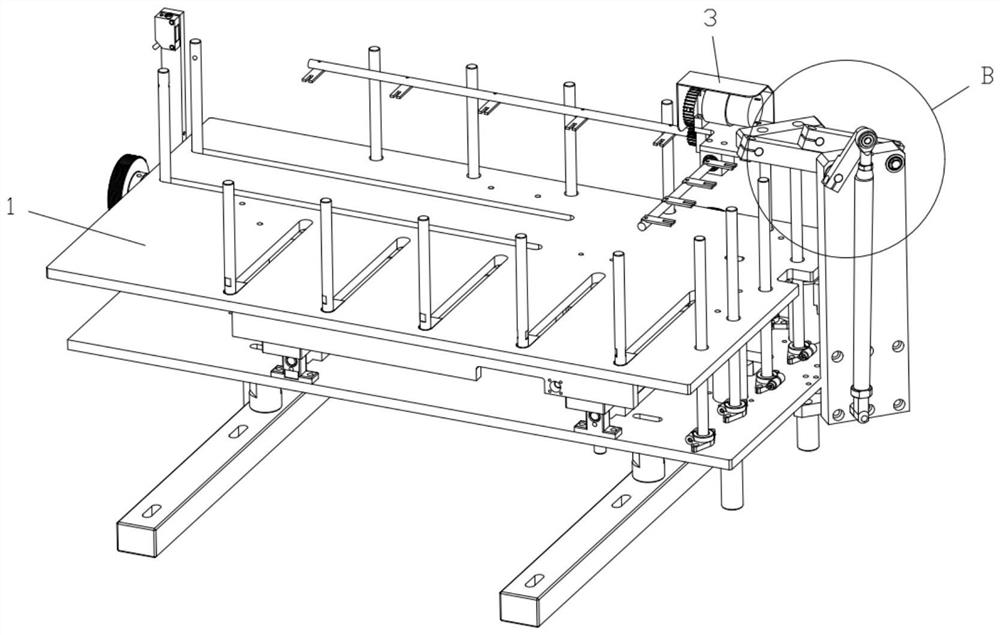

[0029] Please refer to Figure 1-Figure 6 , the present invention proposes a flexible circuit board placement station scraping mechanism, including a placement platform 1, a telescopic mechanism 2, and a scraping device 3. The telescopic mechanism 2 is fixedly connected to one side of the placement platform 1 and is close to the corner. The telescopic mechanism 2 A telescopic arm 21 is provided, and the scraping device 3 is fixedly connected to the telescopic arm 21 and is parallel to the horizontal plane. The scraping device 3 includes a support frame 31, a driving device 32, a first scraping rod 33, a second scraping rod 34, and a support frame 31 is fixedly connected to the telescopic arm 21, and the drive device 32 is fixedly connected to the surface of the support fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com