Three-axis linkage gluing machine with anti-blocking structure

A three-axis linkage and gluing machine technology, applied in the field of gluing machines, can solve problems such as poor gluing effect uniformity, and achieve the effect of ensuring cleanliness and reducing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

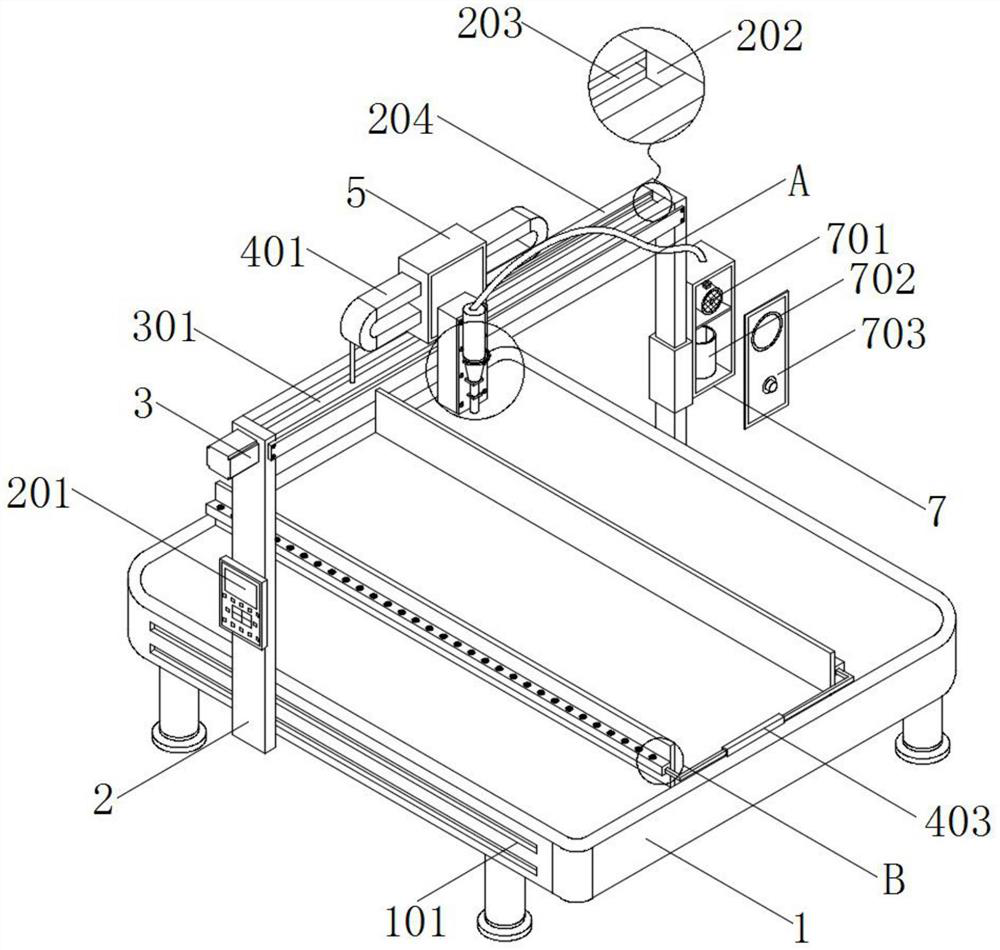

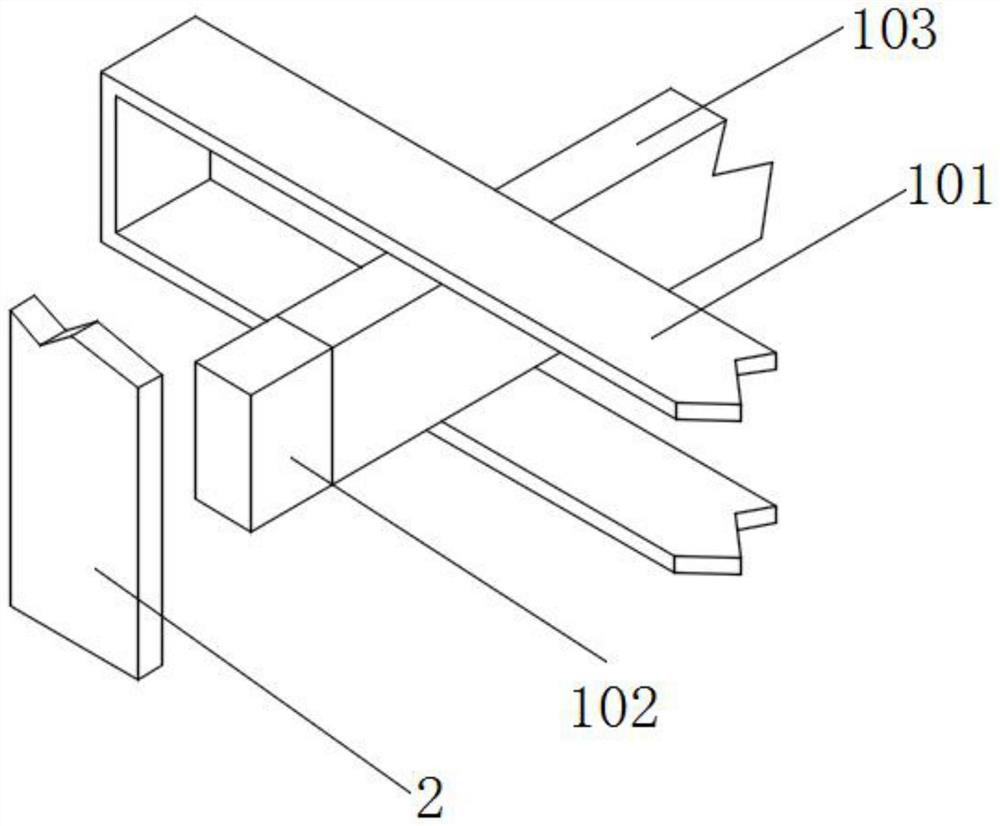

[0046] see figure 1 , image 3 and Figure 8 , an embodiment provided by the present invention: a three-axis linkage gluing machine with an anti-clogging structure, including a gluing machine base 1, the front and back of the gluing machine base 1 are provided with a chute 101, the chute The inside of 101 is slidingly installed with slider 102, and the surfaces of two sets of sliders 102 away from each other are equipped with bracket 2, and the top of bracket 2 is equipped with top plate 204, and the top of top plate 204 is equipped with lifting cylinder 5, and the surface of one side of lifting cylinder 5 is A lifting seat 502 is installed, and a collar 501 is installed on one side surface of the lifting seat 502;

[0047] A limit hoop 503 is installed on the surface of the lifting base 502 , and the limit hoop 503 is located below the collar 501 .

[0048] Specifically, the chute 101 is fitted and slidably connected with the slider 102, which can facilitate the magnetic s...

Embodiment 2

[0056] see figure 1 , Figure 5 and Figure 6 , an embodiment provided by the present invention: a three-axis linkage glue applicator with an anti-clogging structure, including a limit plate 4, and two sets of limit plates 4 arranged front and back are installed on the top of the base 1 of the glue spreader. Side plates 405 are installed on the surfaces of the group of limiting plates 4 that are far away from each other, and laser lights 404 equidistantly arranged are installed on the top of the side plates 405, and telescopic sleeve rods 403 are installed on one side surface of one group of side boards 405, and the telescopic sleeve rods The tail end of 403 is connected with one side surface of another group of side plates 405, and the front and back sides of lifting cylinder 5 are equipped with U-shaped induction bracket 401, and the bottom of induction bracket 401 is equipped with photosensitive sensor 402.

[0057] Specifically, adjust the effective telescopic length of ...

Embodiment 3

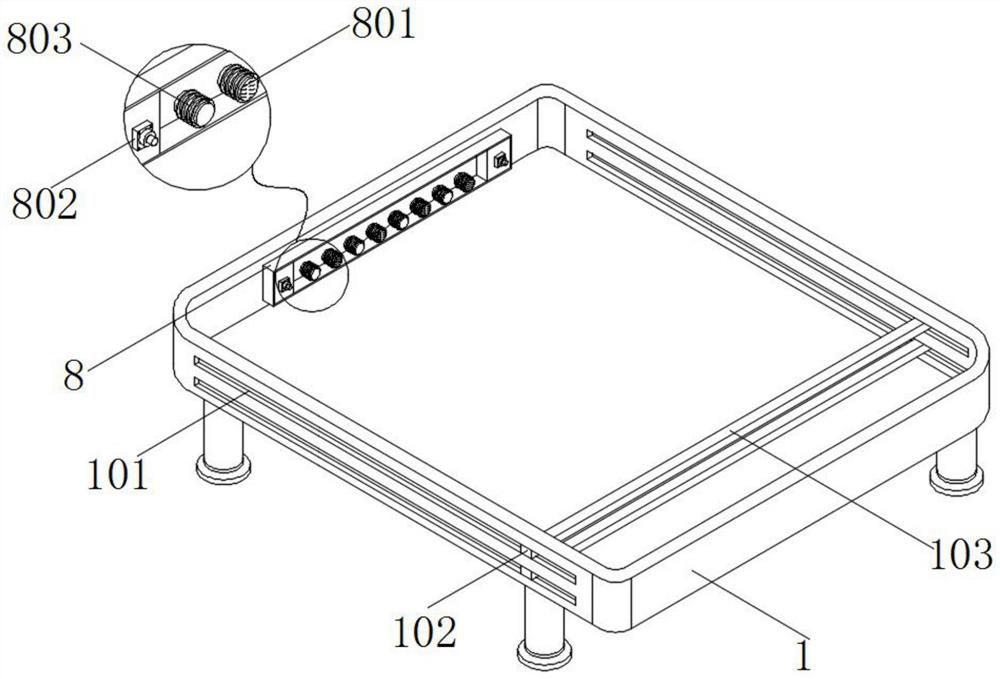

[0060] see figure 2 , an embodiment provided by the present invention: a three-axis linkage glue applicator with an anti-clogging structure, including a suction box 8, a suction box 8 is installed on one side of the base 1 of the glue applicator, and the suction box 8 Two groups of infrared range finders 803 arranged front and back are installed on one side surface of the body, No. 1 electromagnet 801 and No. 2 electromagnet 802 are installed on the side inner wall of the attraction box 8, and No. 1 electromagnet 801 and No. 2 electromagnet 802 are arranged equidistantly. The second electromagnet 802 is arranged at intervals, the magnetic poles of the first electromagnet 801 and the second electromagnet 802 are opposite, and both the first electromagnet 801 and the second electromagnet 802 are electrically connected to the infrared range finder 803 .

[0061] Magnetic strips 103 are installed on the surfaces of two groups of slide blocks 102 that are close to each other. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com