Steel slag stockpiling site covering structure and application method

A technology of covering structure and steel slag, applied in the fields of landfill technology, solid waste removal, etc., can solve the problems of labor and labor in transportation, lagging development and utilization technology, and high cost, and achieve convenient application, low cost, and improve cement strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

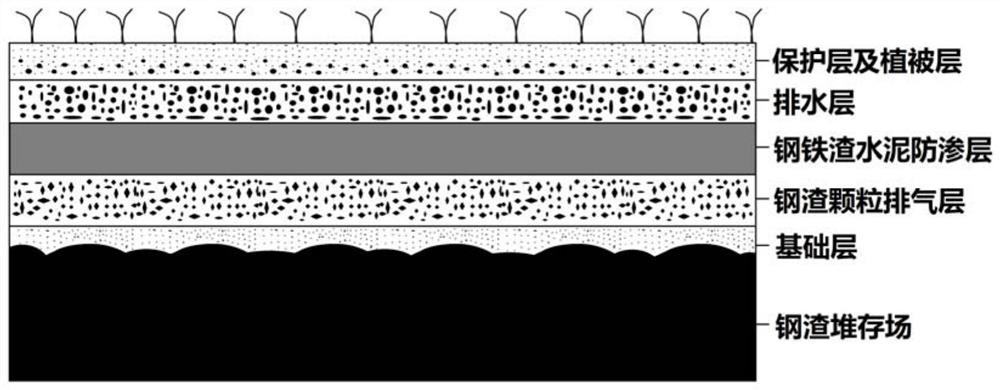

[0028] The cover structure of a steel slag stockpiling site described in this embodiment is a base layer, a steel slag particle exhaust layer, a steel slag cement anti-seepage layer, a drainage layer, a protective layer and a vegetation layer from bottom to top. The base layer in the covering structure of the steel slag storage site adopts the nearby soil materials; the steel slag particle exhaust layer in the covering structure of the steel slag storage site uses granular steel slag as the filling material, and the average particle size of the steel slag is 5mm; the steel slag storage site The composition of the iron and steel slag cement anti-seepage layer is calculated by weight percentage: steel slag (12%), slag (36%), pumice (0%), waste rock (0%), tuff (0%), diatomite (0%), Opal (0%), Sintered Soil (0%), Burnt Shale (0%), Cinder (0%), Fly Ash (0%), Gangue Ash (0%), Limestone (41%), modified bentonite (10%) and gypsum (1%), among which the modified bentonite is applied to ...

Embodiment 2

[0032] The covering structure of a steel slag stockpiling site described in the embodiment includes, from bottom to top, a base layer, a steel slag particle exhaust layer, a steel slag cement anti-seepage layer, a drainage layer, a protective layer and a vegetation layer. The base layer in the covering structure of the steel slag storage site adopts the nearby soil materials; the steel slag particle exhaust layer in the covering structure of the steel slag storage site uses granular steel slag as the filling material, and the particle size of the steel slag is 7mm; the steel slag storage site The composition of the steel slag cement anti-seepage layer is calculated by weight percentage: steel slag (8%), slag (32%), pumice (1%), waste rock (1%), tuff (1%), diatomite ( 1%), opal (1%), sintered soil (1%), burnt shale (1%), cinder (1%), fly ash (1%), gangue ash (1%), limestone ( 42%), modified bentonite (5%) and gypsum (3%), of which the modified bentonite is a polymer-modified al...

Embodiment 3

[0036] The covering structure of a steel slag stockpiling site described in the embodiment includes, from bottom to top, a base layer, a steel slag particle exhaust layer, a steel slag cement anti-seepage layer, a drainage layer, a protective layer and a vegetation layer. The base layer in the covering structure of the steel slag storage site adopts the nearby soil materials; the steel slag particle exhaust layer in the covering structure of the steel slag storage site uses granular steel slag as the filling material, and the particle size of the steel slag is 10mm; the steel slag storage site The composition of steel slag cement anti-seepage layer is calculated by weight percentage: steel slag (1%), slag (9%), pumice (4%), waste rock (4%), tuff (4%), diatomite ( 4%), opal (4%), sintered soil (4%), burnt shale (4%), cinder (4%), fly ash (4%), gangue ash (4%), limestone ( 44%), modified bentonite (1%) and gypsum (5%), of which the modified bentonite is a polymer-modified alkali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com