Iron-based magnetic powder forming process and equipment

A molding process and molding equipment technology, applied in the direction of inductance/transformer/magnet manufacturing, electrical components, circuits, etc., can solve the problem of product magnetic performance decline and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

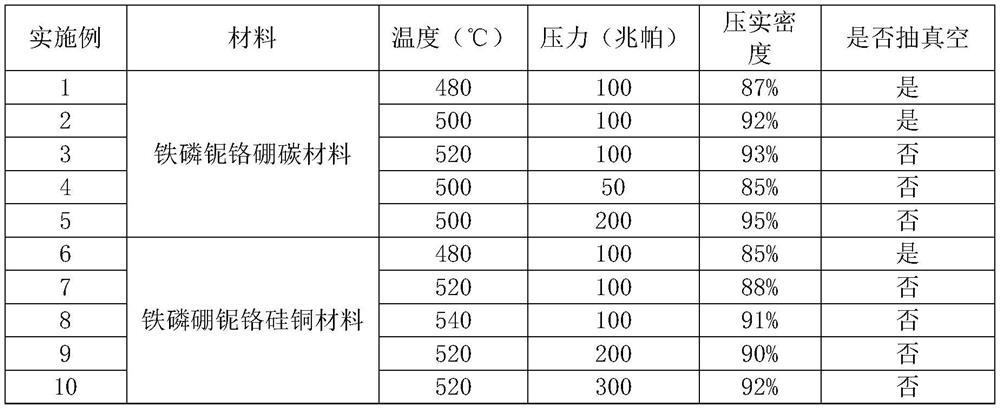

Embodiment 1

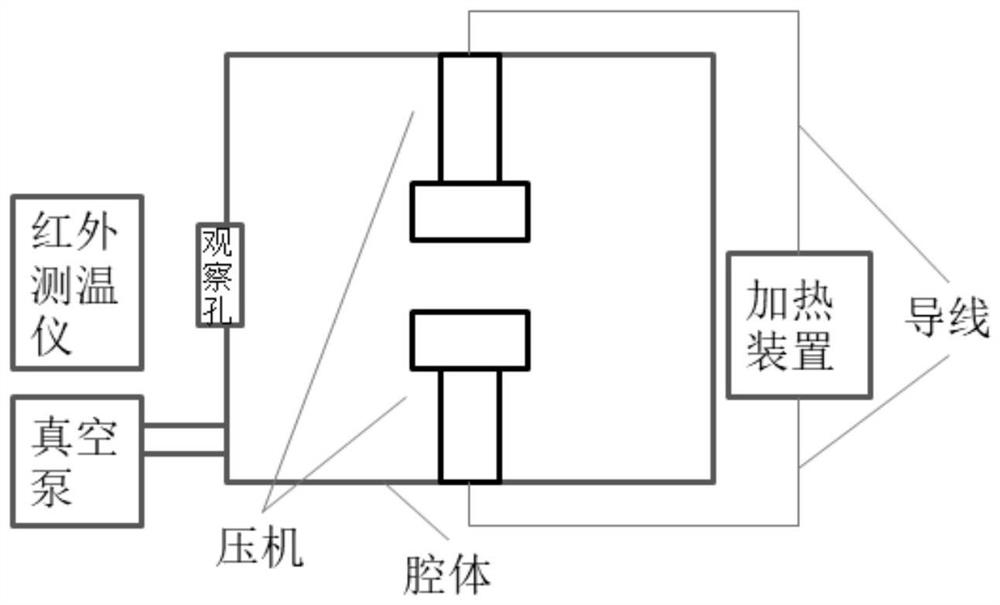

[0047] The iron-based magnetic powder molding process in this embodiment includes the following steps:

[0048] Take an appropriate amount of iron, phosphorus, niobium, chromium, and boron carbon materials, put the iron, phosphorus, niobium, chromium, and boron carbon materials into the mold, evacuate the cavity, pass current on the press, and conduct conductive heating on the iron, phosphorus, niobium, chromium, and boron carbon materials through the mold. When the heating temperature reaches 480°C, pressurize the iron-phosphorus-niobium-chromium-boron-carbon material through the press, and when the pressure reaches 100 MPa, pressurize the iron-phosphorus-niobium-chromium-boron-carbon material in the mold. After the phosphorus-niobium-chromium-boron-carbon material is formed, it is taken out, and the compaction density of the formed iron-phosphorus-niobium-chromium-boron-carbon material is measured to be 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com