Direct-current brushless motor rotor and forming method thereof

A brushless DC motor and rotor technology, which is used in the manufacture of motor generators, stator/rotor bodies, electromechanical devices, etc., can solve the problems of reducing the distribution density of permanent magnets, affecting the fixing of permanent magnets, reducing rotor speed, etc. The loss of small magnets, improving stability, and the effect of high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

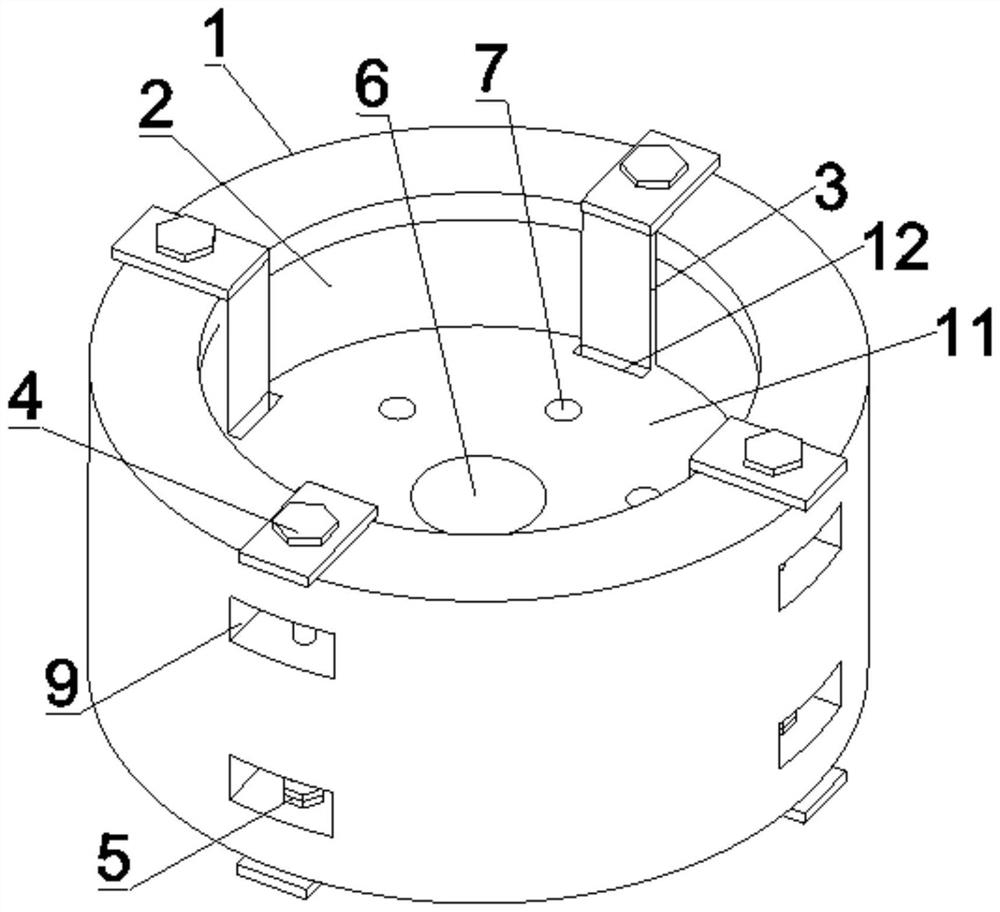

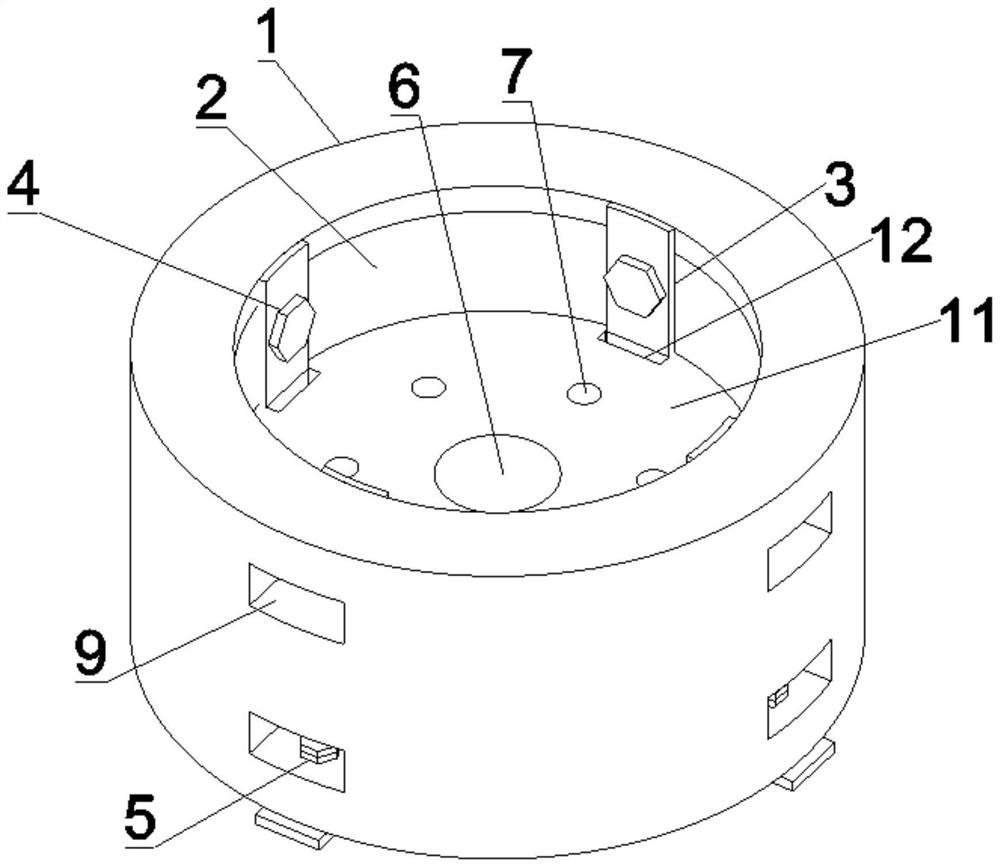

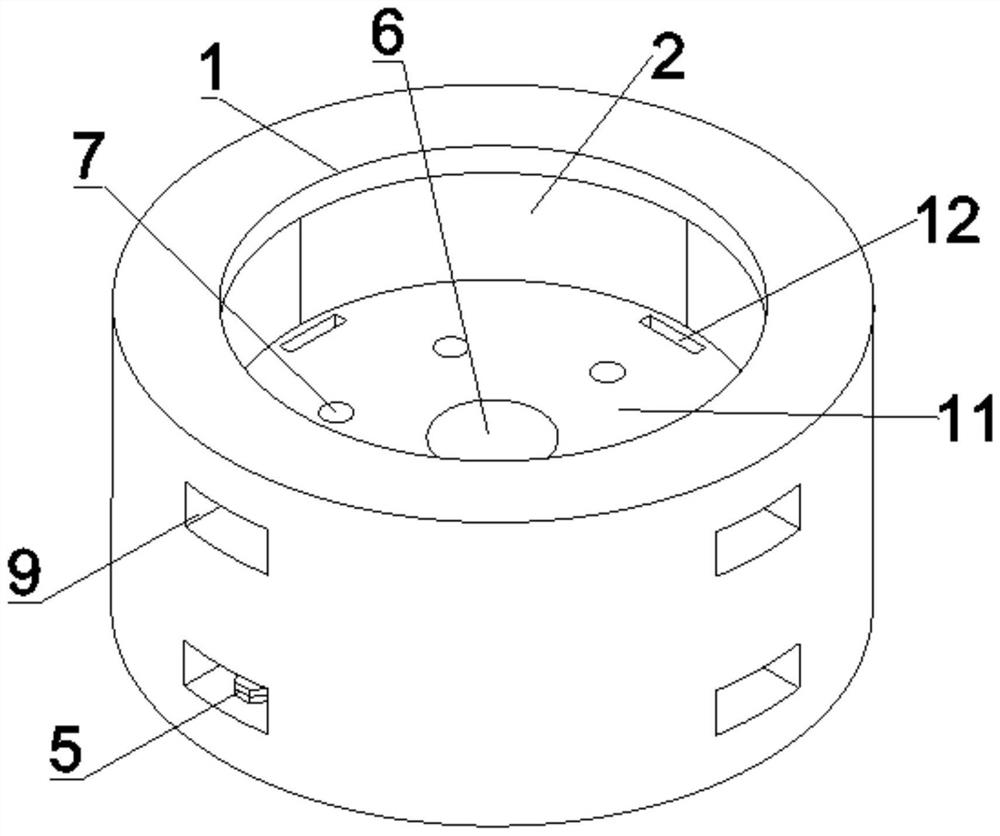

[0034] see Figure 1-7 As shown, the present embodiment is a brushless DC motor rotor, which includes a rotor housing 1 and a permanent magnet 2. The bottom end of the rotor housing 1 is provided with an end cover 6, and several permanent magnets 2 are annularly distributed on the inner wall of the rotor housing 1. There is a mortise and tenon structure between two adjacent permanent magnets 2, and it is fixed by a fixed frame 3. It should be noted that the fixed frame 3 is U-shaped, and the U-shaped fixed frame 3 is more convenient and quick to install, saving the cost of permanent magnets 2. fixed time.

[0035] The fixed frame 3 has the same shape as the position where two adjacent permanent magnets 1 abut against each other, which facilitates better fixing between the two permanent magnets 2 .

[0036] One side of the fixing frame 3 passes through the end cover 11 through the rectangular hole 12 between the end cover 11 and the rotor casing 1, and the upper and lower ends...

Embodiment 2

[0044] see Figure 1-7 As shown, the present embodiment is a brushless DC motor rotor, which includes a rotor housing 1 and a permanent magnet 2. The bottom end of the rotor housing 1 is provided with an end cover 6, and several permanent magnets 2 are annularly distributed on the inner wall of the rotor housing 1. There is a mortise and tenon structure between two adjacent permanent magnets 2, and it is fixed by a fixing frame 3. It should be noted that the fixing frame 3 is L-shaped, and the L-shaped fixing frame 3 makes the permanent magnet 2 be fixed more stably, and the The safety of the rotor during operation is ensured.

[0045] The fixed frame 3 has the same shape as the position where two adjacent permanent magnets 1 abut against each other, which facilitates better fixing between the two permanent magnets 2 .

[0046] One side of the fixing frame 3 passes through the end cover 11 through the rectangular hole 12 between the end cover 11 and the rotor casing 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com