External-rotating permanent magnet motor

A permanent magnet motor, external rotation technology, applied in synchronous motors with static armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of insufficient strength, permanent magnet sticking With problems such as unreliable positioning, it can achieve the effect of improving braking efficiency, stable strength and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

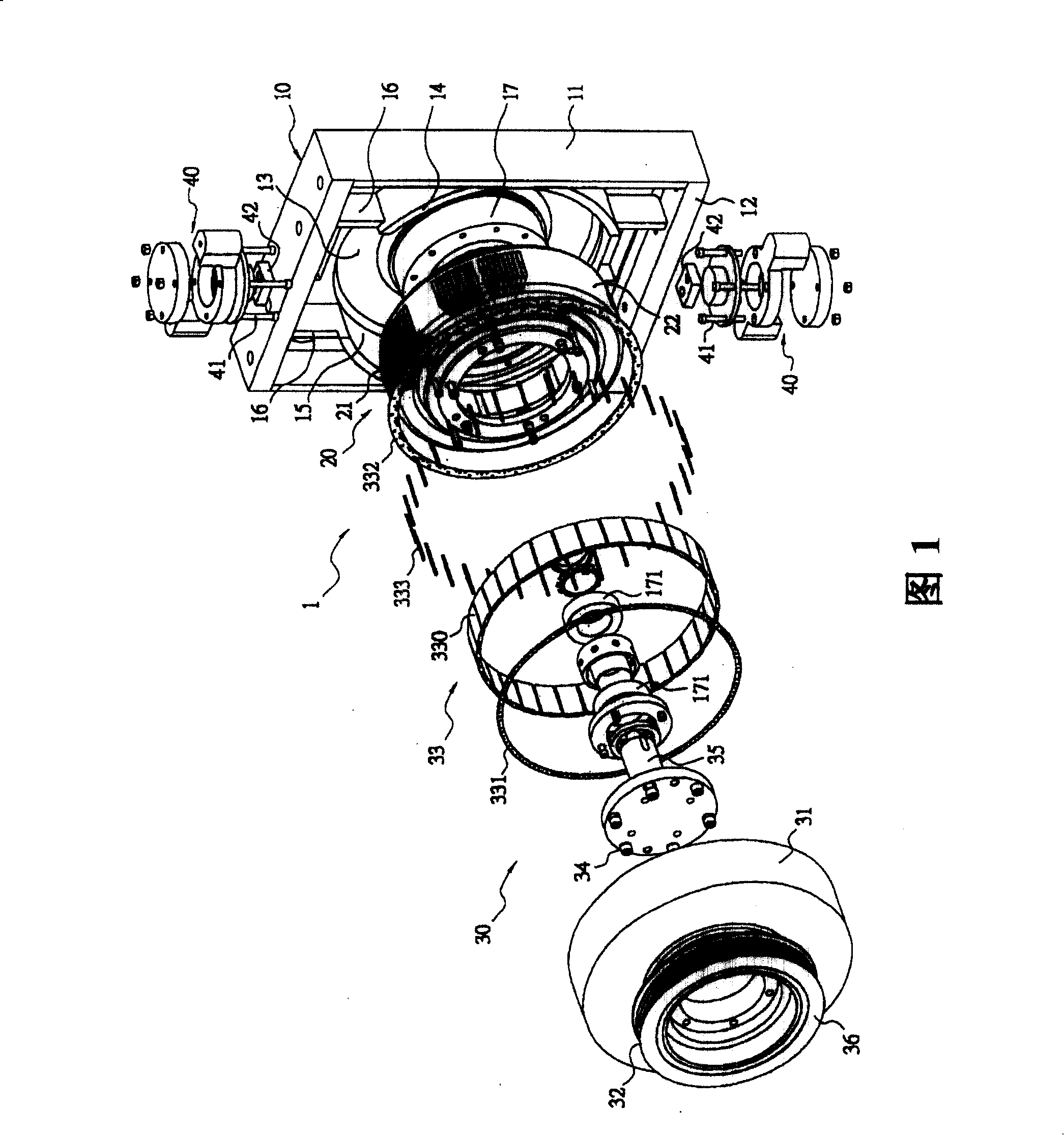

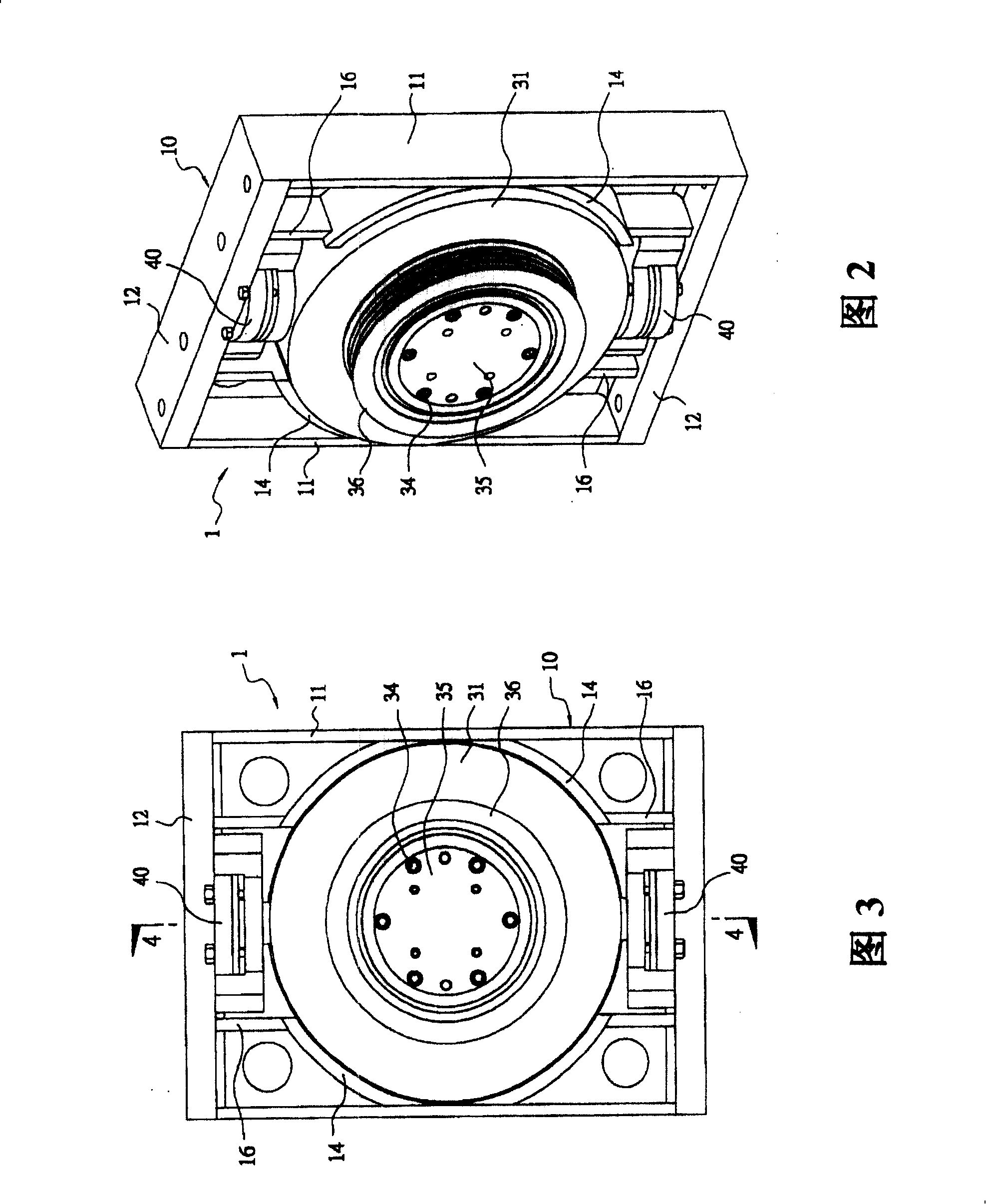

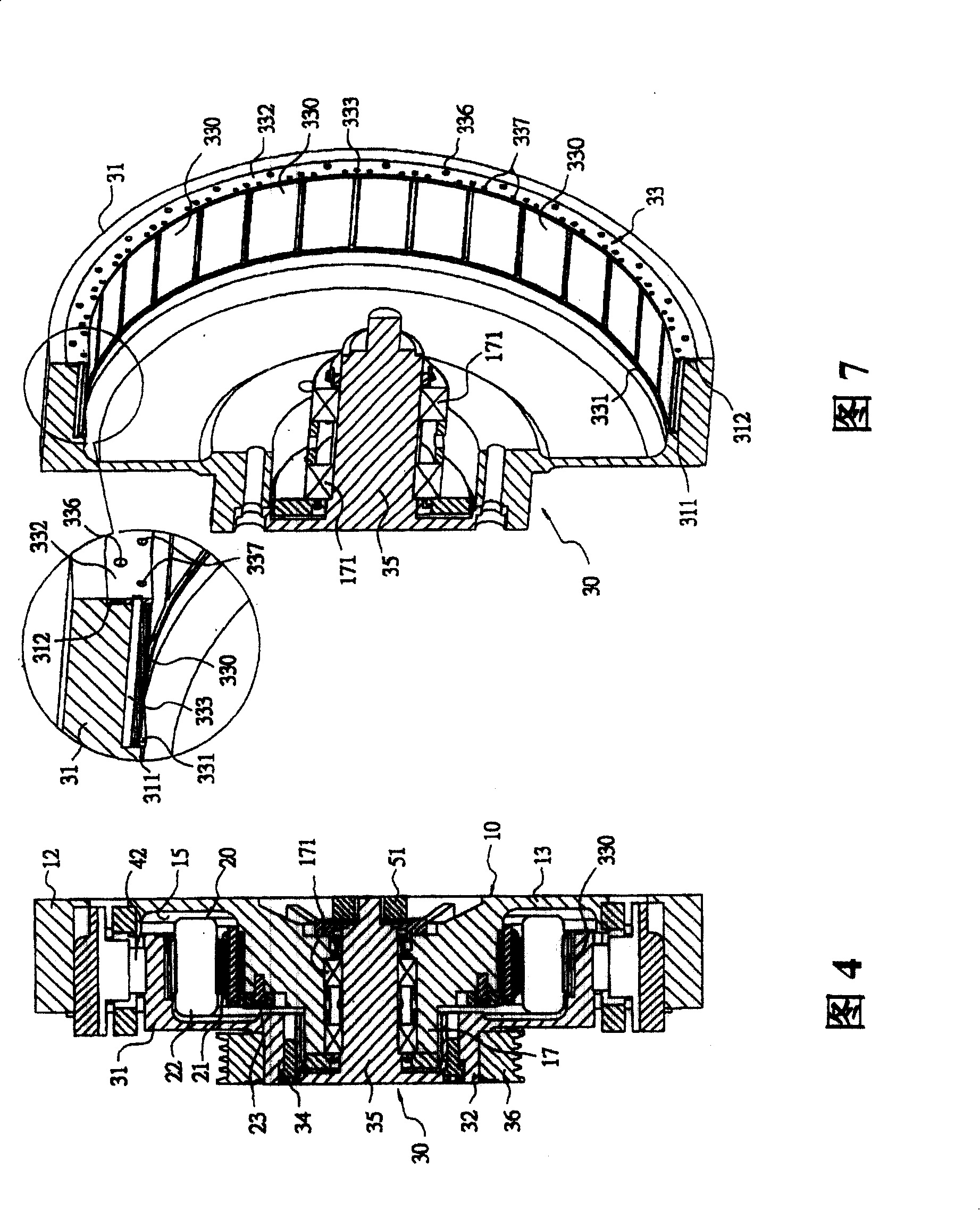

[0076] First of all, please refer to Fig. 1 and compare Fig. 2 to Fig. 4, the external rotation permanent magnet motor 1 of the present invention mainly includes: a base body 10, the outer frame of which includes two side structures 11 in the direction of the long axis, and two short The side structure 12 in the axial direction, the base 10 has a bottom 13 on one side, and the other side is open, and contains a pair of semi-annular reinforcing ribs 14 in the direction of the long axis to form a storage chamber 15, and two pairs of reinforcement ribs in the direction of the long axis. The reinforcing ribs 16 are respectively connected between the two ends of the two halves of the annular reinforcing ribs 14 and the side structure 12 in the direction of the minor axis and become one; the center of the base 10 extends from the bottom 13 toward the storage chamber 15 with a hollow bearing Cover 17, and is provided with a plurality of bearings 171 in its central shaft hole.

[0077...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com