Metal processing protection mechanism

A protection mechanism and metal processing technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as potential safety hazards, vibration of operating parts, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

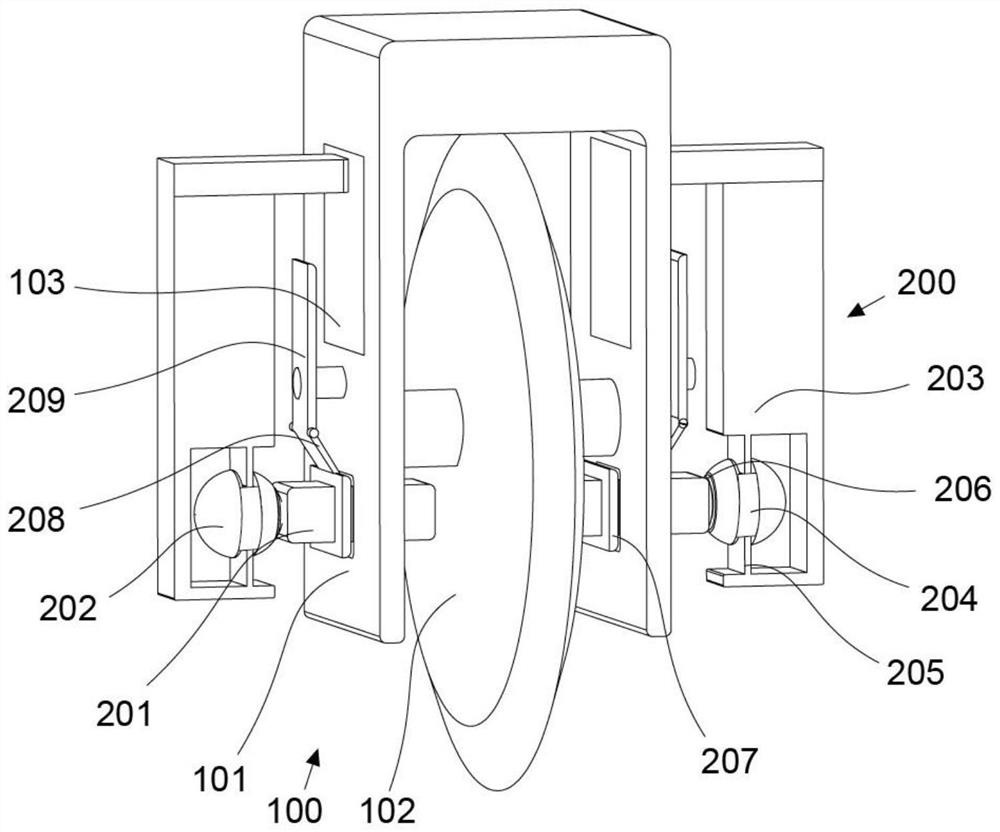

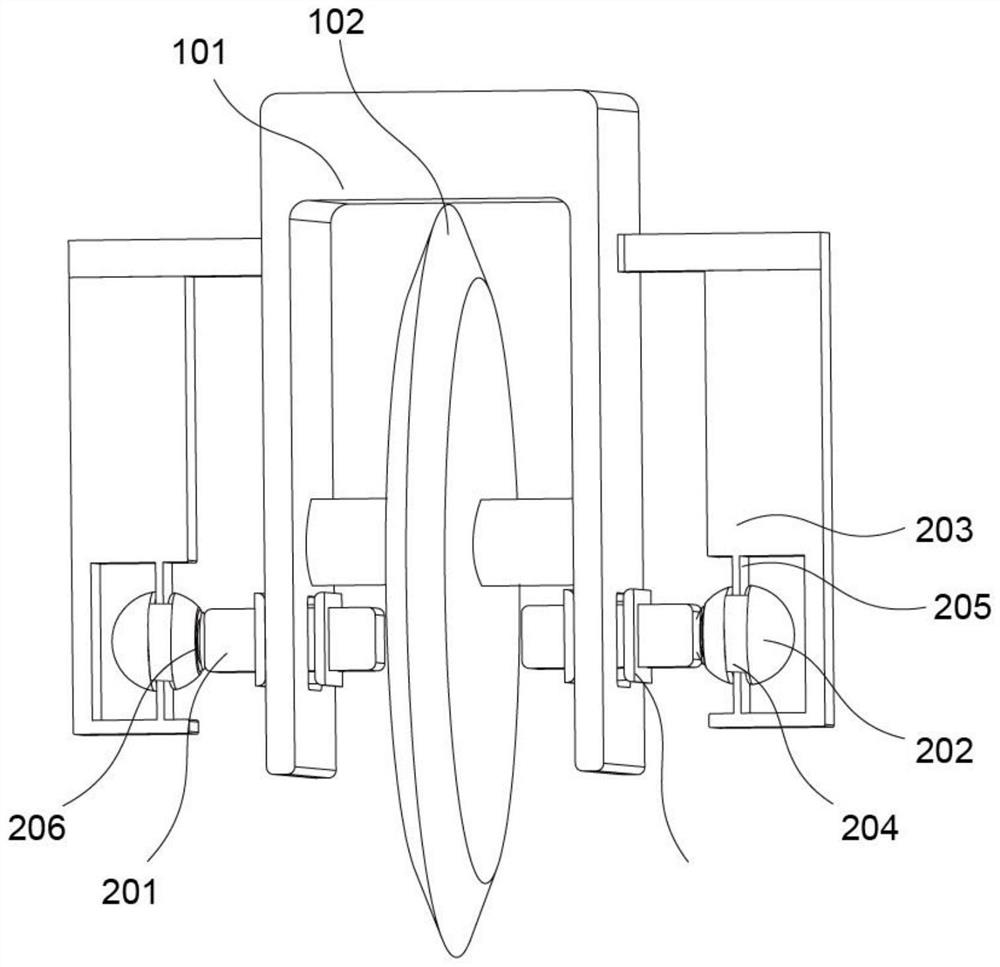

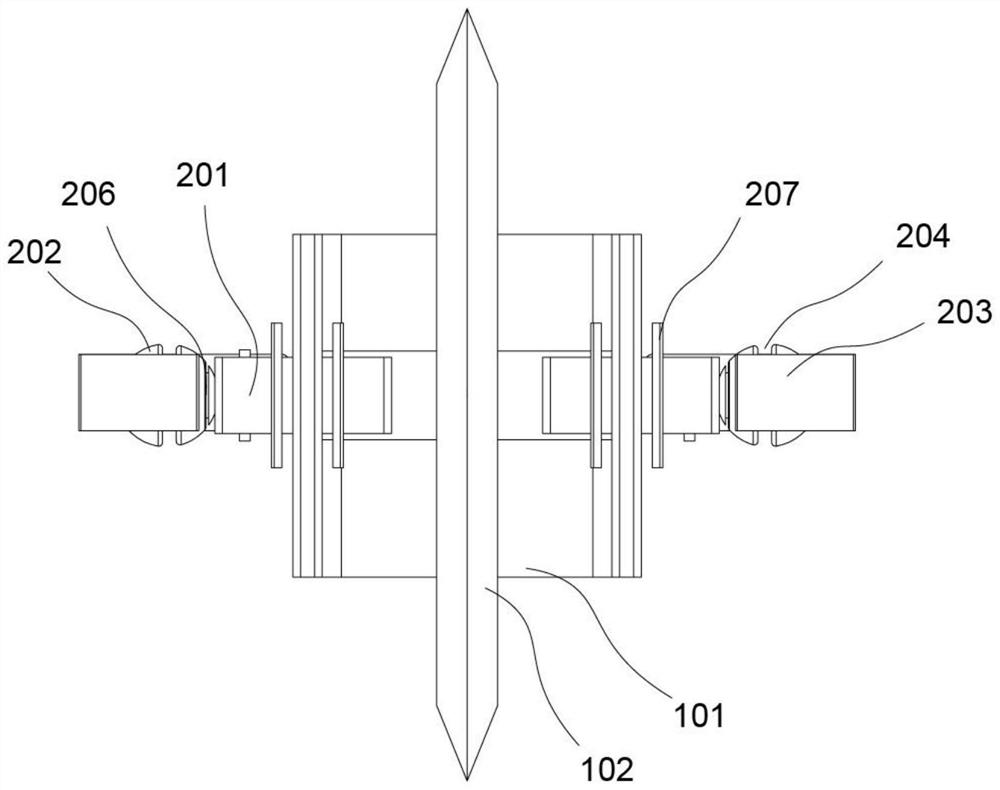

[0025] refer to Figure 1-3 , provides a schematic diagram of the overall structure of a metal processing protection mechanism, a metal processing protection mechanism includes a frame assembly 100, including a main frame 101 and a processing disc 102 arranged on the main frame 101; and, a protection assembly 200, including a set The trigger bar 201 on both sides of the main frame 101 , the limit ball 202 arranged at one end of the trigger bar 201 , and the protection plate 203 matched with the limit ball 202 .

[0026] Specifically, a metal processing protection mechanism includes a frame assembly 100, including a main frame 101 and a processing disc 102 arranged on the main frame 101, the main frame 101 is a U-shaped frame, and the processing disc 102 is placed in it; and, the protection The assembly 200 includes trigger bars 201 arranged on both sides of the main frame 101, and a limit ball 202 arranged at one end of the trigger bar 201. The trigger bars 201 are arranged cl...

Embodiment 2

[0029] refer to Figure 1-3 , this embodiment is different from the first embodiment in that: the limit ball 202 is provided with a card slot 204, and the protective plate 203 is provided with a limit elastic piece 205 that cooperates with the card slot 204, and the limit elastic piece 205 is placed in the card slot 204; the end of the limit ball 202 away from the protective plate 203 is provided with a chute 206 that cooperates with the limit shrapnel 205; the two sides of the main frame 101 are provided with openings, and the trigger bar 201 is placed in the opening, and the trigger bar 201 is provided with Clamping plates 207 located on both sides of the opening; the diameter of the clamping plate 207 is larger than the size of the opening, the material of the clamping plate 207 is rubber, and the other structures are the same as in Embodiment 1.

[0030] Specifically, the limit ball 202 is provided with a card slot 204, and the protective plate 203 is provided with a limit...

Embodiment 3

[0035] refer to Figure 1-3 What this embodiment is different from the above embodiments is: the top of the clamping plate 207 is fixedly connected with a push plate 208, the top of the push plate 208 is movably connected with a movable plate 209, and the movable plate 209 is rotatably connected with the main frame 101; the main frame 101 is provided with The stabilizing plate 103 that cooperates with the movable plate 209, the stabilizing plate 103 is movably connected with the main frame 101; the bottom of the protective plate 203 is provided with a cavity, and the limit ball 202 is placed therein, and the limit ball 202 is not in contact with the inner wall of the cavity. The position elastic pieces 205 are fixedly arranged on the top and bottom of the cavity; the trigger bar 201 is located on both sides of the processing disk 102, and the rest of the structure is the same as that of the second embodiment.

[0036]Specifically, the top of clamping plate 207 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com