Embedded exposed steel bar rust removal equipment for constructional engineering

A kind of construction engineering and pre-embedded technology, which is applied in the direction of metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of unguaranteed personal safety, high labor intensity, and low safety of derusting workers, and achieve Prevention of impact on human health, high safety, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

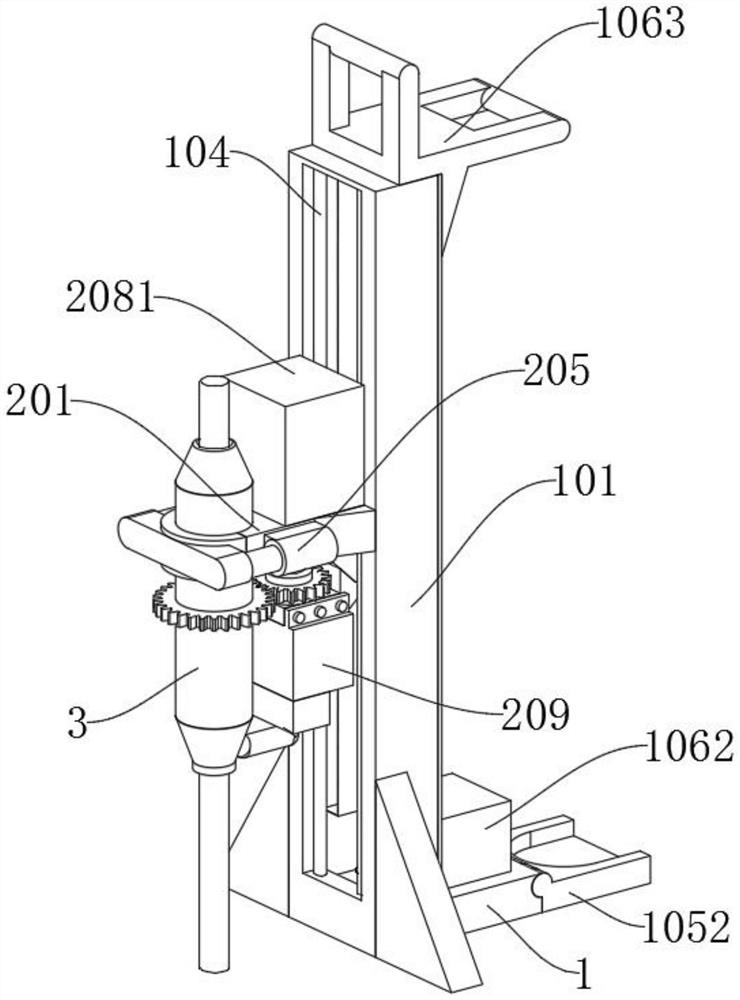

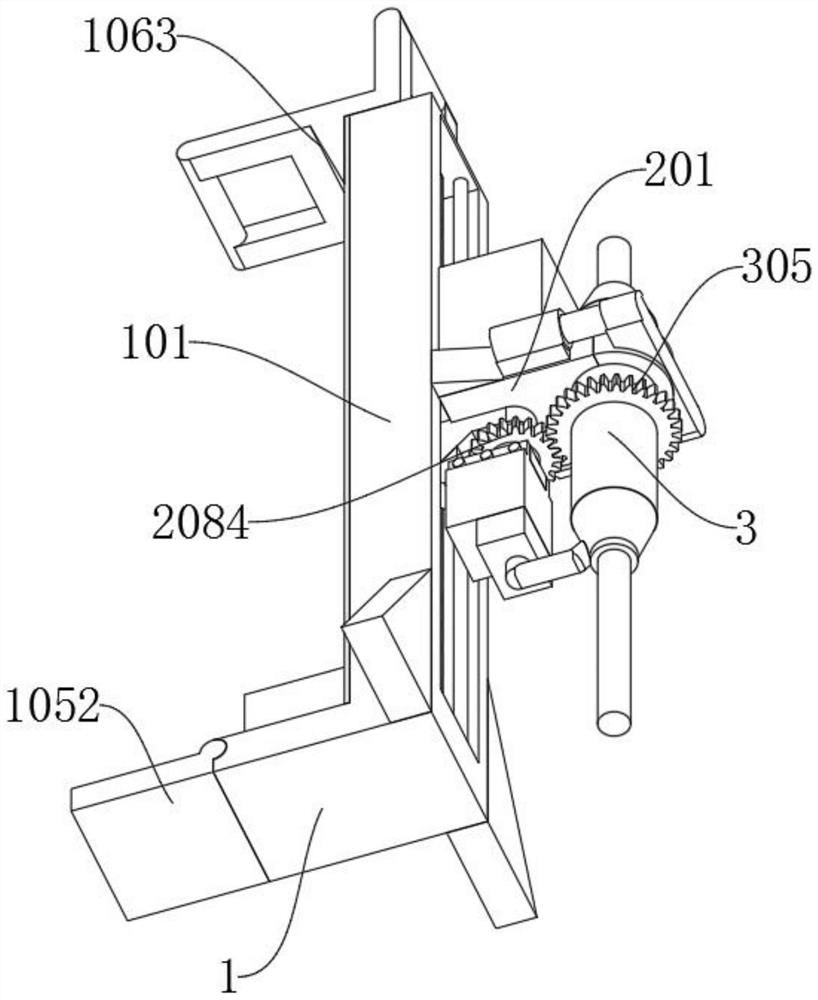

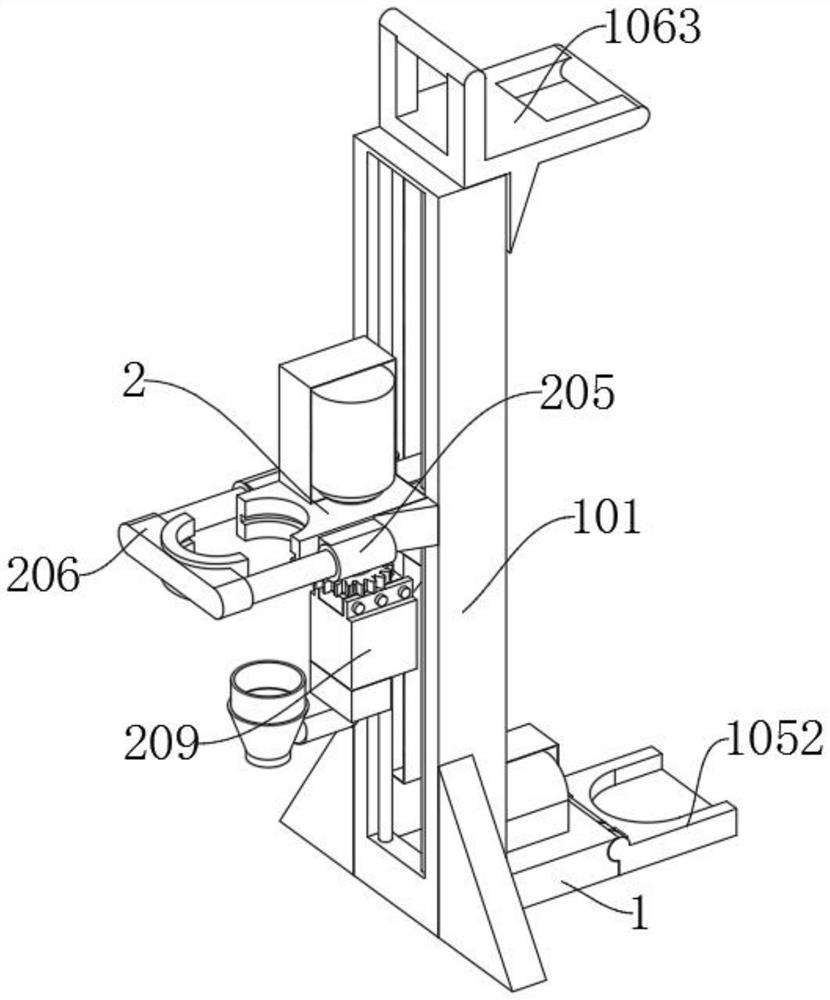

[0045] Example: Please refer to Figure 1 to Figure 9 :

[0046] The present invention proposes a pre-buried exposed steel bar derusting equipment for construction engineering, comprising: a bearing base 1;

[0047] One end of the top of the bearing base 1 is integrally provided with an assembly pillar 101, one side of the assembly pillar 101 is provided with a protective structure, and one side of the bearing base 1 is provided with a bearing positioning structure; the adjustment carrier 2 is installed on the side of the assembly pillar 101 , an assembly carrier 201 is installed on one side of the adjustment carrier 2, a driving structure is installed on the top of the assembly carrier 201, and a collection structure is arranged at the bottom of the assembly carrier 201; the cleaning carrier 3, the cleaning carrier 3 is installed on the assembly carrier 201- side.

[0048] Such as Figure 4 to Figure 6 As shown, the adjustment carrier 2 includes:

[0049]The load bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com