Cab assembly with high torsional rigidity

A technology of torsional stiffness and cab, applied in the field of cab, can solve the problems of difficult manual activities, inconvenient fire extinguishing, loss, etc., and achieve the effects of good deformation resistance, strength improvement, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

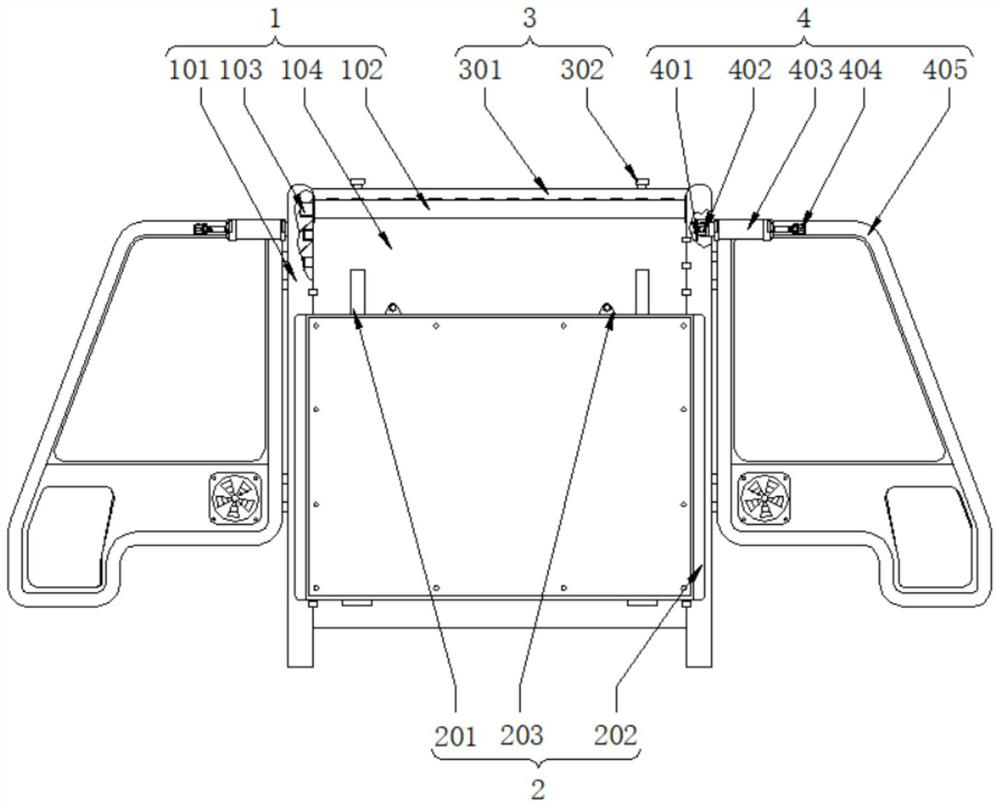

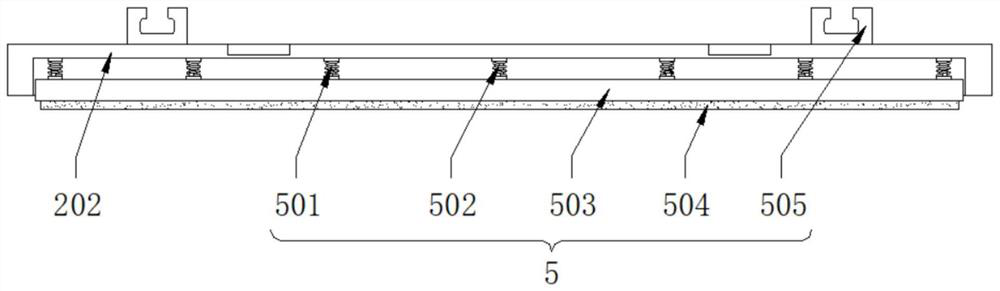

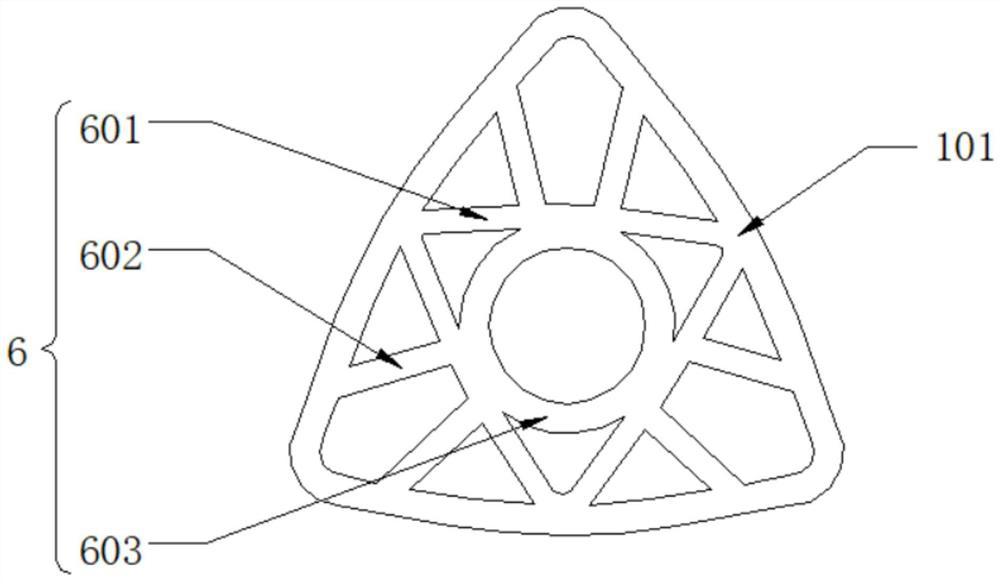

[0027] Such as Figure 1-3 As shown, a cab assembly with strong torsional rigidity includes a combination mechanism 1 and an exchange mechanism 3. A placement mechanism 2 is installed in the rear middle of the combination mechanism 1. The exchange mechanism 3 is fixed on the top of the combination mechanism 1, and the combination mechanism 1 An opening and closing mechanism 4 is installed on both sides of the upper side, a protective mechanism 5 is installed inside the placement mechanism 2, and a strengthening mechanism 6 is fixed inside the combination mechanism 1. Cover plate 104, crossbeam 102 is fixed on the upper side of frame beam 101, and the middle part of both sides of crossbeam 102 is fixed with plug-in end 103, and the rear surface of frame beam 101 is fixed with rear cover plate 104, through plug-in end 103, can During processing, the crossbeam 102 and the frame beam 101 are plugged together, and then welded at the joint. Similarly, the fixing method of the rear c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com