Modular crawler-type transfer machine and self-assembly method thereof

A crawler and transfer machine technology, applied to tracked vehicles, transportation and packaging, motor vehicles, etc., can solve problems such as difficult to handle, difficult to control, difficult to reach, etc., to achieve efficient assembly, ensure stability and applicability, and reduce equipment The effect of the model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

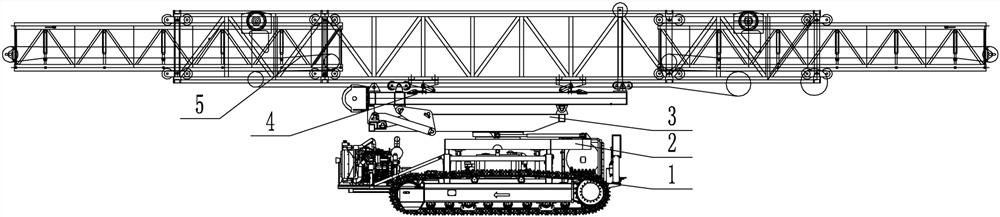

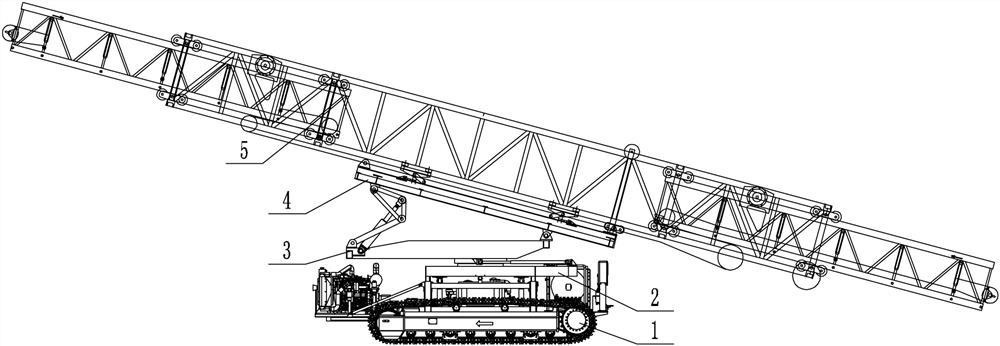

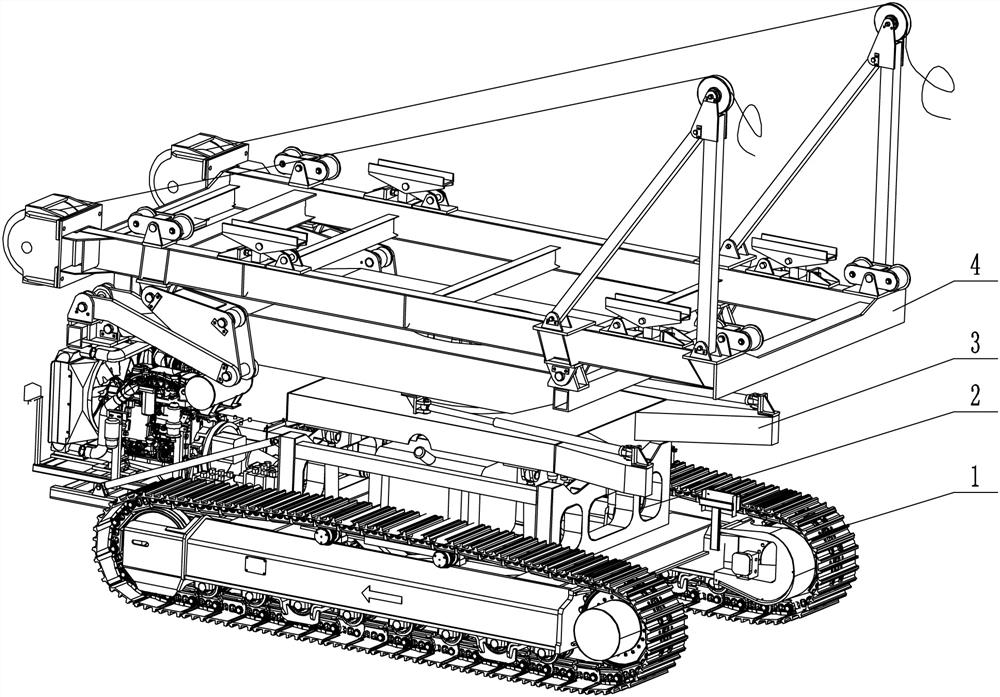

[0048] see Figure 1-14 , a modular crawler transfer machine, which includes a crawler chassis 1 for walking and carrying control devices, a leveling device 2 is mounted on the bottom beam of the crawler chassis 1; a leveling device 2 is mounted on the top of the leveling device 2 There is a turning device 3, and the top of the turning device 3 is equipped with a telescopic belt conveyor 5 through a lifting device 4; ° level adjustment and ±45° rotation adjustment; the lifting device 4 can realize the independent assembly of the telescopic belt conveyor 5 and the crawler chassis 1, and can realize the maximum variable one-way inclination angle of the telescopic belt conveyor 5 of 15° Work inclination adjustment. By adopting the above-mentioned transfer machine, which adopts a modular design, the whole machine is decomposed into two assembly modules: a crawler chassis and a telescopic belt conveyor, and the modules can be independently and efficiently assembled on the job site...

Embodiment 2

[0059] The self-assembly method of any one of the modular crawler-type transfer machines, the modular crawler-type transfer machine includes a crawler-type chassis 1 equipped with a leveling device 2, a turning device 3 and a lifting device 4, and a telescopic belt conveyor The two assembly modules of the machine 5 are installed through the cooperation of the lifting device 4 and the winch mechanism to realize the independent assembly of the crawler-type telescopic transfer machine. The specific installation method includes the following steps:

[0060] Step1: Place the crawler chassis 1 with the leveling device 2, the slewing device 3 and the lifting device 4 and the telescopic belt conveyor 5 on a relatively flat site, and adjust the crawler chassis by using a helicopter or lifting equipment 1. Align with the telescopic belt conveyor 5 in the longitudinal direction;

[0061] Step2: Start the crawler chassis 1 and gradually approach the telescopic belt conveyor 5, the jacking...

Embodiment 3

[0066] In order to ensure that the belt of the telescopic belt conveyor 5 is always in a horizontal state when working on uneven roads, the leveling device can be used to perform the action to realize the horizontal adjustment of the telescopic belt conveyor 5 at ±5° in the horizontal direction. The leveling device includes Fix the lower bracket 201 , the first deflection oil cylinder 202 , the second deflection oil cylinder 203 , the swing upper bracket 204 , the first hinge seat 205 , and the second hinge seat 206 .

[0067] Further, the small cavity of the first deflection cylinder 202 is connected in series with the large cavity of the second deflection cylinder 203, the large cavity of the first deflection cylinder 202 is connected in series with the small cavity of the second deflection cylinder 203, and the large and small cavities of the cylinders are connected in series to ensure that the two Side thrust speeds are equal.

[0068] Further, when the left side of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com