Multi-channel discharging device of coffee packaging machine

A packaging machine, multi-channel technology, applied in the field of coffee packaging, can solve the problems of low packaging efficiency, unable to meet the needs of multi-channel blanking, etc., to achieve improved production efficiency, accurate and controllable blanking amount, and large stirring area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The structure of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments. It should be noted that this embodiment is illustrative rather than limiting.

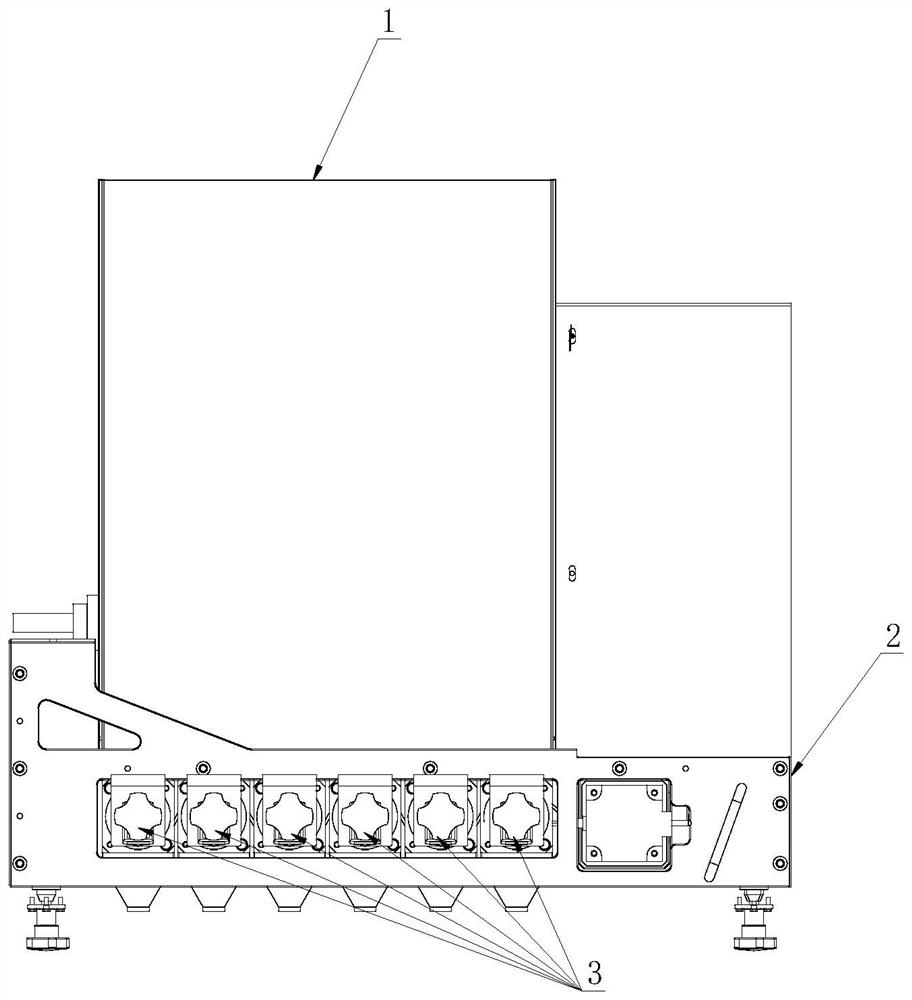

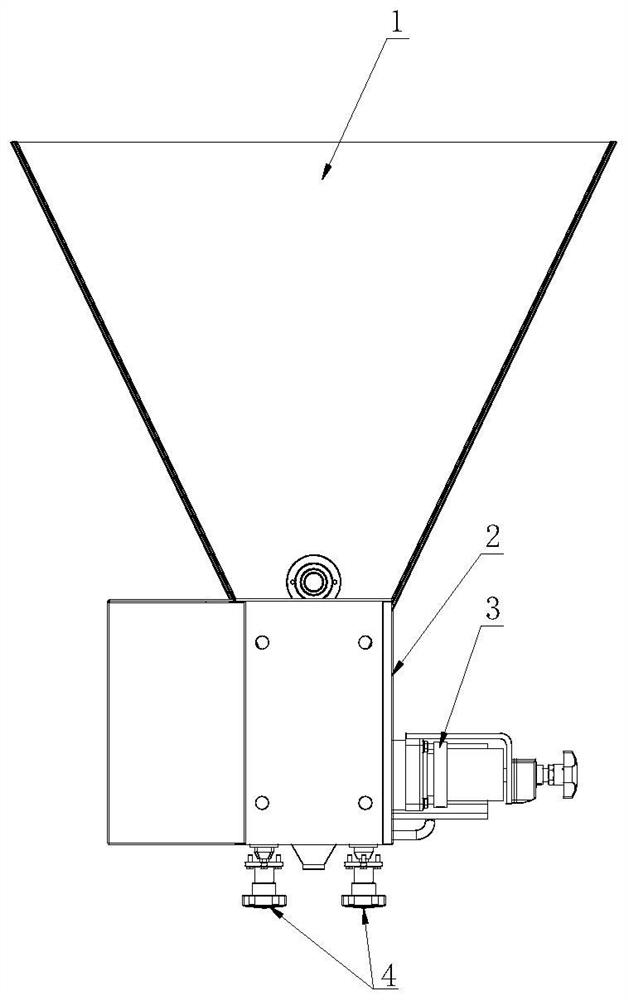

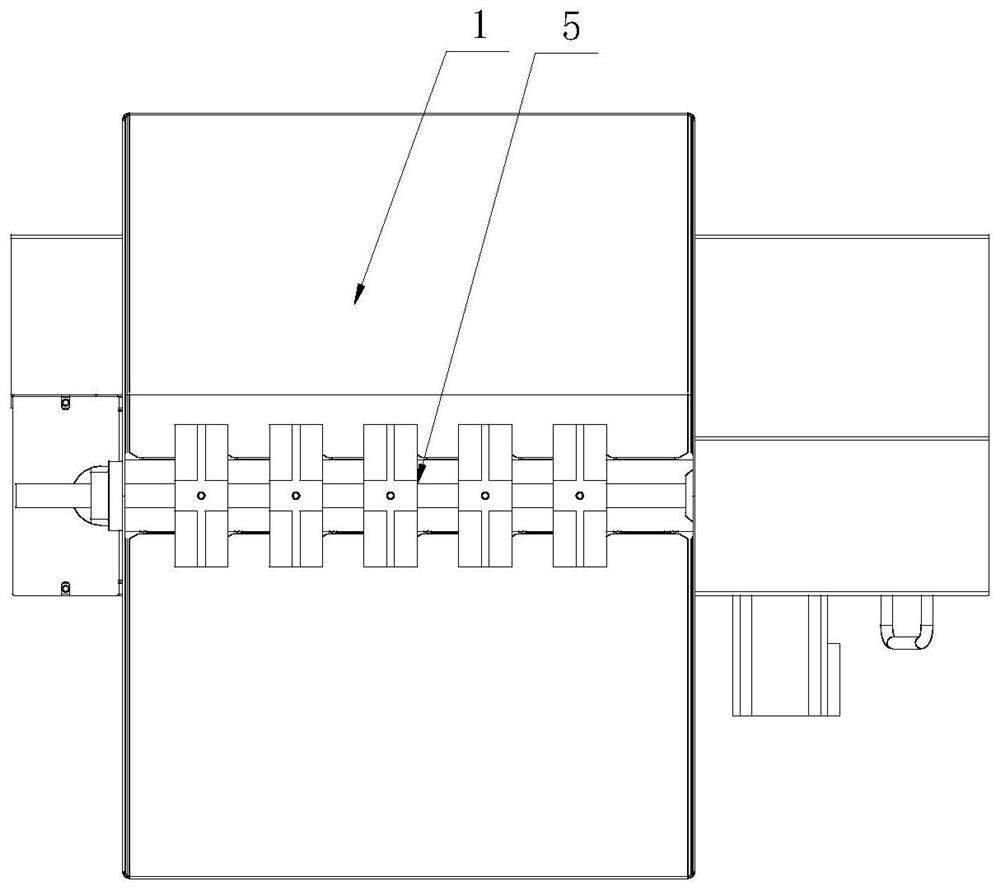

[0034] A multi-channel unloading mechanism on a coffee packaging machine, please refer to Figure 1-9 , Its invention points are: mainly comprise unloading bin 1, unloading platform 2, unloading mixing mechanism 5, multi-group unloading unit 3 and unloading drive mechanism 9 with adjustable feed volume.

[0035] The lower silo is a funnel-shaped square silo, the upper end of which is the feed end, and adopts an open end structure; the lower end is the discharge end, and the discharge bottom plate 1.1 is welded below the discharge end, corresponding to the bottom of the discharge bottom plate. A plurality of rectangular discharge through-holes 1.2 are evenly distributed along the left and right directions of the silo, and the size of the discharge thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com