Bubble film and bubble bag

A technology of bubble film and bubble bag, applied in the direction of container, container, transportation and packaging to prevent mechanical damage, can solve the problem of poor buffering capacity of bubble film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

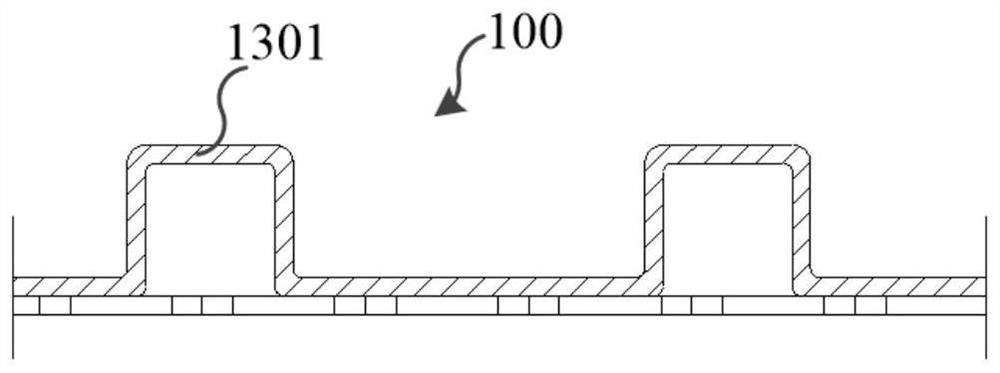

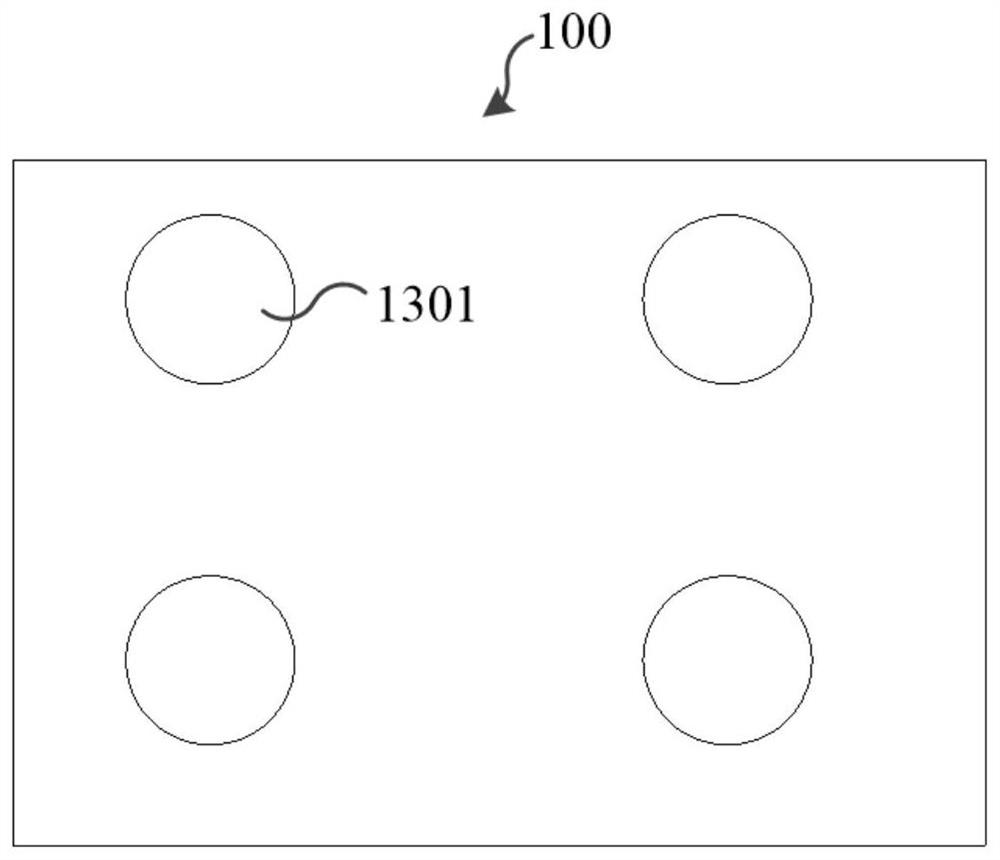

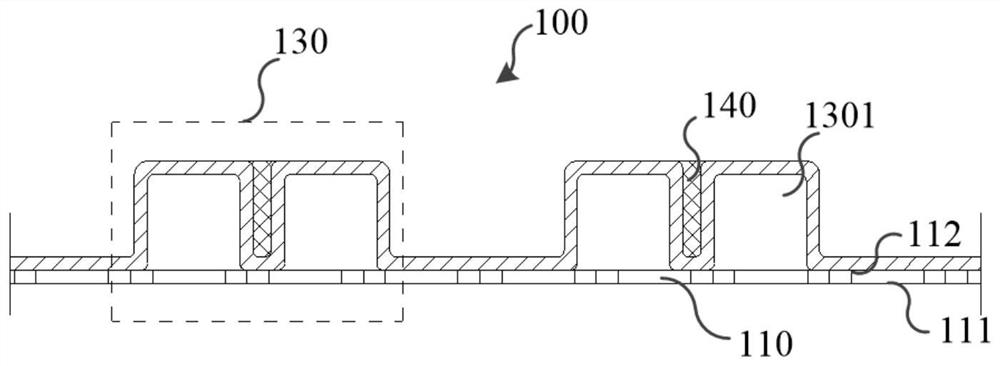

[0101] In a first alternative embodiment, refer to Figure 7-Figure 12 As shown, in the thickness direction of the air bubble film 100 , the first air bubbles 131 and the second air bubbles 132 are dislocated, and the adjacent side walls of the first air bubbles 131 and the second air bubbles 132 are connected to each other.

[0102] Such arrangement can also improve the cushioning capacity of the air bubble film 100 and the air bubble bag including the air bubble film 100 . The adjacent side walls of the first bubble 131 and the second bubble 132 are connected to each other, so as to improve the transmission reliability of the gas pressure force of the adjacent bubbles 1301 along the direction perpendicular to the thickness of the bubble film 100 .

[0103] Specifically, the connection of adjacent side walls of the first air bubbles 131 and the second air bubbles 132 close to each other may include the following two feasible implementation manners:

[0104] As a first possib...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap