Ampoule bottle opening scratching equipment

A technology for ampoule bottles and equipment, which is applied in the field of ampoule bottle mouth scratching equipment, which can solve the problems of low scratching efficiency of ampoule bottles, and achieve the effects of easy collection, good scratching, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

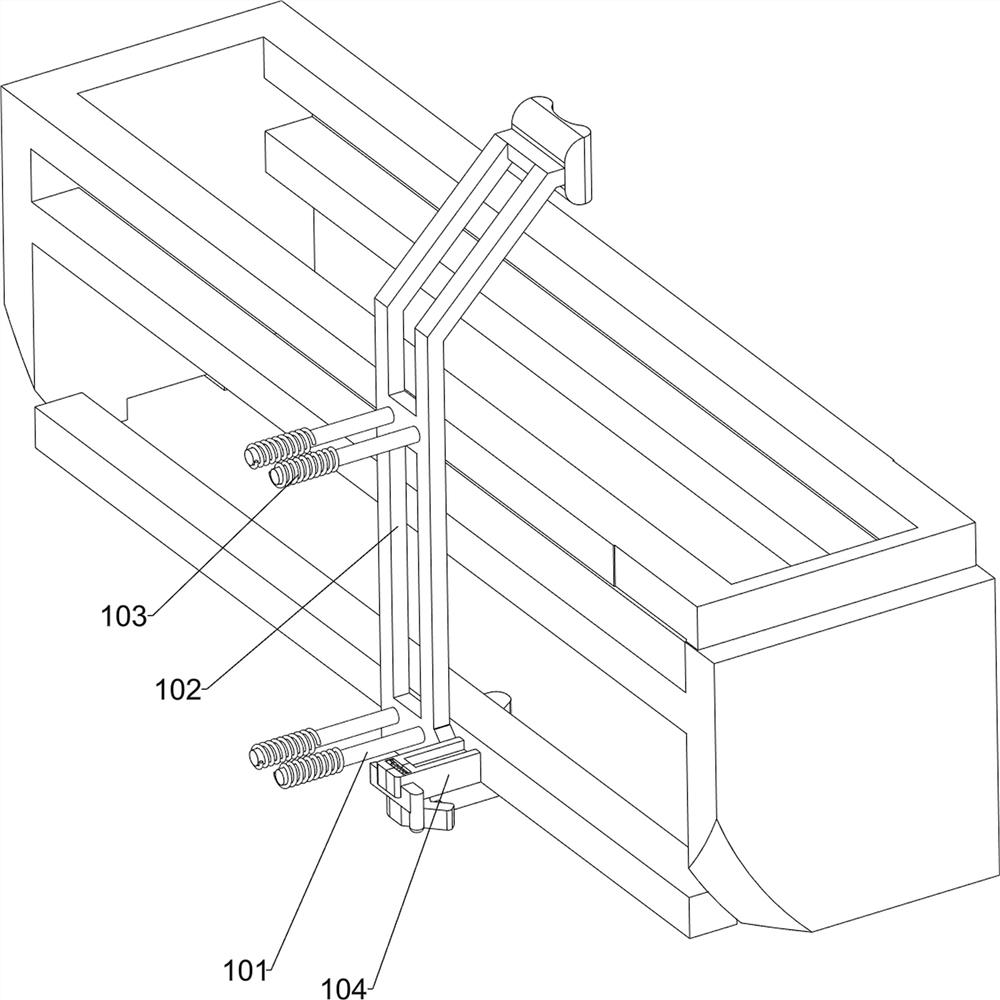

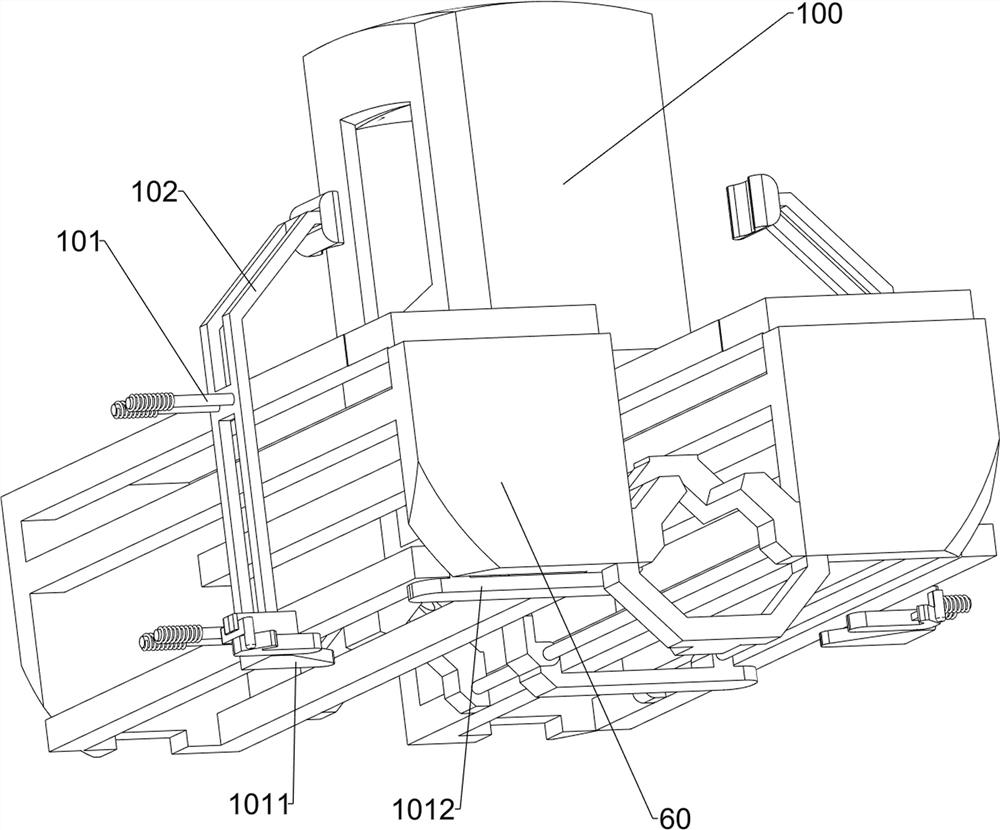

[0042] An ampoule bottle neck scratching device, such as Figure 1 to Figure 7 As shown, it includes a casing 1, a first support block 2, a scratch knife 3, a first guide rod 4, a first spring 5, a placement mechanism 6 and a power mechanism 7, and the left and right sides of the rear of the casing 1 are connected with first Support block 2, first support block 2 inner sides are all connected with the first guide rod 4, all sliding type is provided with sliding block on the first guide rod 4, all rotary type is provided with scratch knife 3 on the sliding block, sliding block and the first A first spring 5 is connected between the guide rods 4, and the first springs 5 are all sleeved on the first guide rod 4. The left and right sides of the housing 1 are provided with a placement mechanism 6, and the placement mechanism 6 is connected to the first spring on both sides. A block 2 is connected, and the lower part of the rear side of the placement mechanism 6 is provided with a...

Embodiment 2

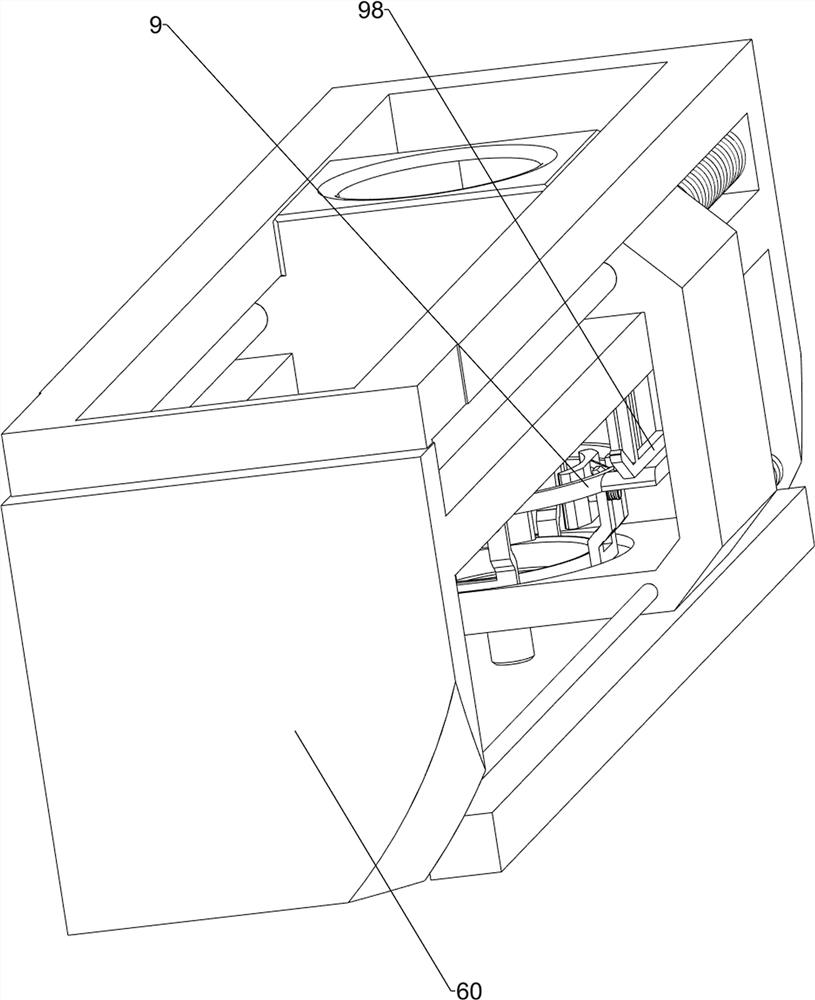

[0047] On the basis of Example 1, such as Figure 8 to Figure 20 As shown, it also includes a circulation assembly 8, and the circulation assembly 8 includes a third support block 80, a cylinder 81, a guide frame 82, a first rotating rod 83, a rack 84, a first gear 85, a fourth support block 86, a transmission Wheel 87, belt 88 and the second stop block 89, the front and rear sides between the second support block 60 are all connected with the 3rd support block 80, and cylinder 81 is installed between the 3rd support block 80, the expansion and contraction of cylinder 81 A rack 84 is connected to the bar, and a guide frame 82 is fixedly connected between the second support block 60 bottoms. Rotating rod 83, first rotating rod 83 upper bottom is all connected with first gear 85, and first gear 85 is meshed with rack 84, and the fourth supporting block 86 is all connected between the upper part of the front and rear sides of the second supporting block 60, the first The four su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com