Method for efficiently and controllably chopping carbon nanotubes in gas phase

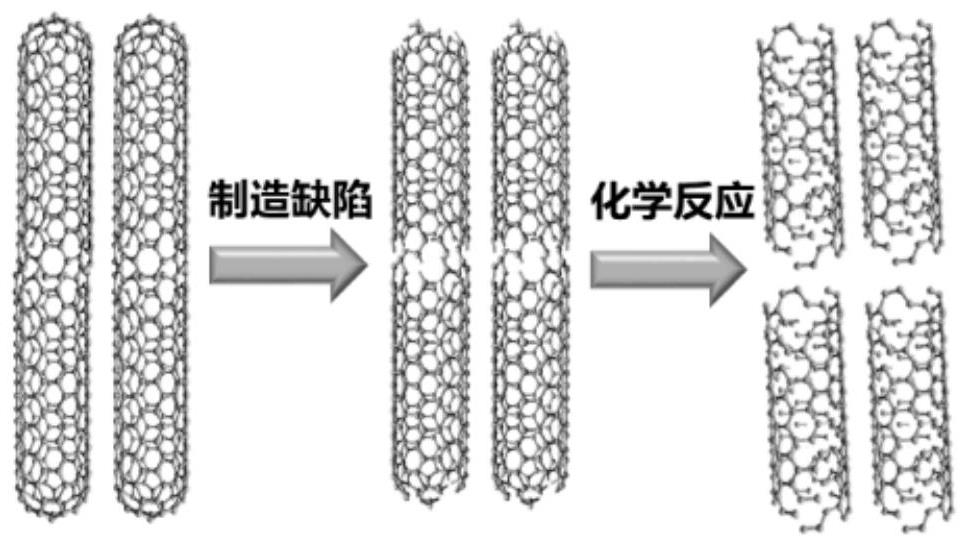

A technology of carbon nanotubes and chopping, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., and can solve the problem of intrinsic structure damage of chopped carbon nanotubes, poor controllability of chopped carbon nanotubes, and short-cut carbon nanotubes. Low yield of nanotubes and other problems, to achieve the effect of high efficiency, strong controllability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0038] Example 1.

[0039] In this embodiment, the method of high-efficiency controllable short-cut carbon nanotubes is as follows:

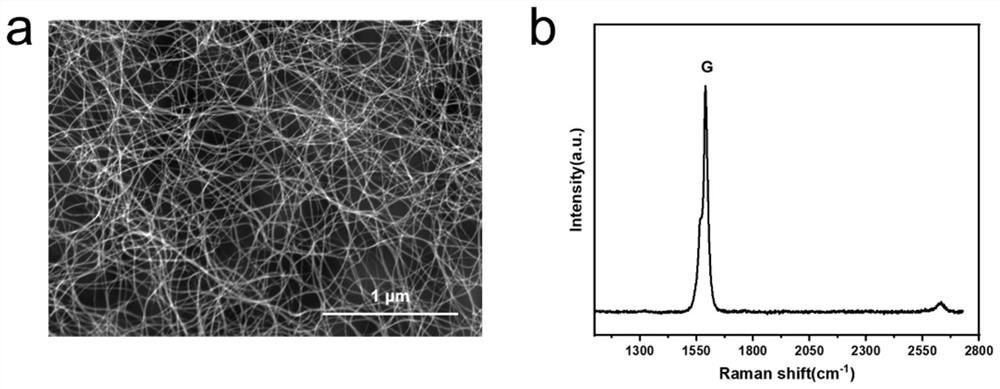

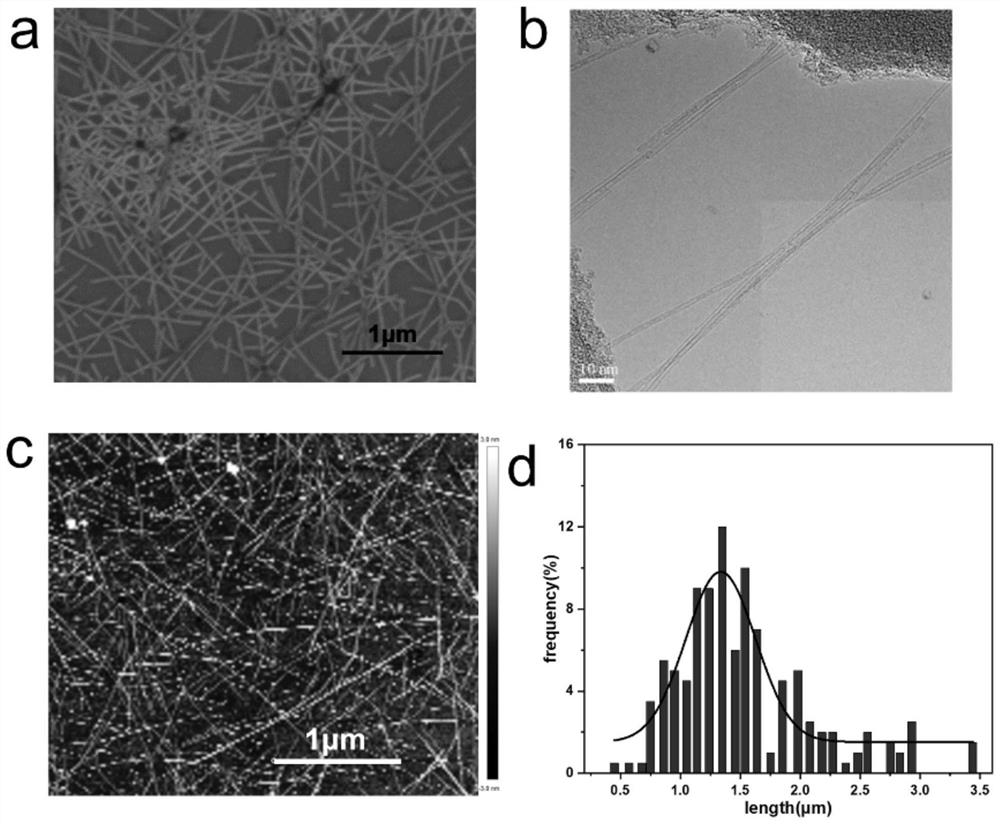

[0040] (1) Dispersion of carbon nanotubes

[0041] Weigh 4.5mg surfactant (poly (3-dodecylthiophene-2,5-di)), 3 mg carbon nanotube ( figure 2 And 15 ml of toluene and mixed in the reagent bottle, and the ultrasonic dispersion was performed at a power of 200 W for 30 min to give a carbon nanotube dispersion. Well 10 min in a water bath at 60 ° C to obtain a carbon nanotube dispersed in a silicon substrate surface ( image 3 . Among them, the carbon nanotubes are single-walled carbon nanotubes having a length of 50 μm and a diameter of 2 nm.

[0042] (2) High temperature heat treatment carbon nanotubes

[0043] The resulting dispersed carbon nanotube silicon-based silicon nanotubes were placed in the quartz boat in the quartz boat, and the quartz boat was placed in the constant temperature zone of the tube furnace. Under the protection of argon (volume...

Example Embodiment

[0048] Example 2 Changes the aspigenic homoperative condition to regulate the short cut length of carbon nanotubes.

[0049] In this embodiment, the method of high-efficiency controllable short-cut carbon nanotubes is as follows:

[0050] (1) Dispersion of carbon nanotubes. Similarly to step (1) in Example 1.

[0051] (2) The heat treatment of carbon nanotubes. As in step (2) in Example 1.

[0052] (3) Air plasma treatment of carbon nanotubes. The air plasmon processing time of 3 W is 10s, and other steps (3) in Example 1 are the same.

[0053] (4) The gas phase cut treatment of carbon nanotubes. As in step (4) in Example 1. The morphology and length distribution of the carbon nanotubes after the short cut Image 6 Indicated. From Image 6 A carbon tube can be seen in a few paragraphs, and the length distribution statistics ( Image 6 b), the average length is 121 nm and the length ranges from 75 to 200 nm. Comparative Example 1, the average length was shortened by 54 nm. It has prov...

Example Embodiment

[0054] Example 3 Regulating gas phase reaction kinetics control the length of the short cut carbon nanotubes.

[0055] In this embodiment, the method of high-efficiency controllable short-cut carbon nanotubes is as follows:

[0056] (1) Dispersion of carbon nanotubes. Similarly to step (1) in Example 1.

[0057] (2) The heat treatment of carbon nanotubes. As in step (2) in Example 1.

[0058] (3) Hydrogen plasma treatment of carbon nanotubes. As in step (3) in Example 1.

[0059] (4) The gas phase cut treatment of carbon nanotubes. Unlike Example 1, the reaction temperature was 780 ° C, the concentration of water vapor was 5000 ppm, and the treatment time was 15 min.

[0060] This embodiment achieves a short cut length regulation by regulating the reaction temperature, etch gas concentration and reaction time, etc. Figure 7 Indicated. From Figure 7 A carbon nanotube is known as a short cut, the atomic force microscope statistics and calculates its average length of 91 nm. Figure 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap