Intelligent fluff raw material storage bin

A technology for storing silo and raw materials, which is applied in spray/jet textile material processing, textile and papermaking, fiber opening and cleaning machines, etc. To achieve the effect of saving the waiting time of humidification and soaking, changing the scattered pollution and increasing the dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

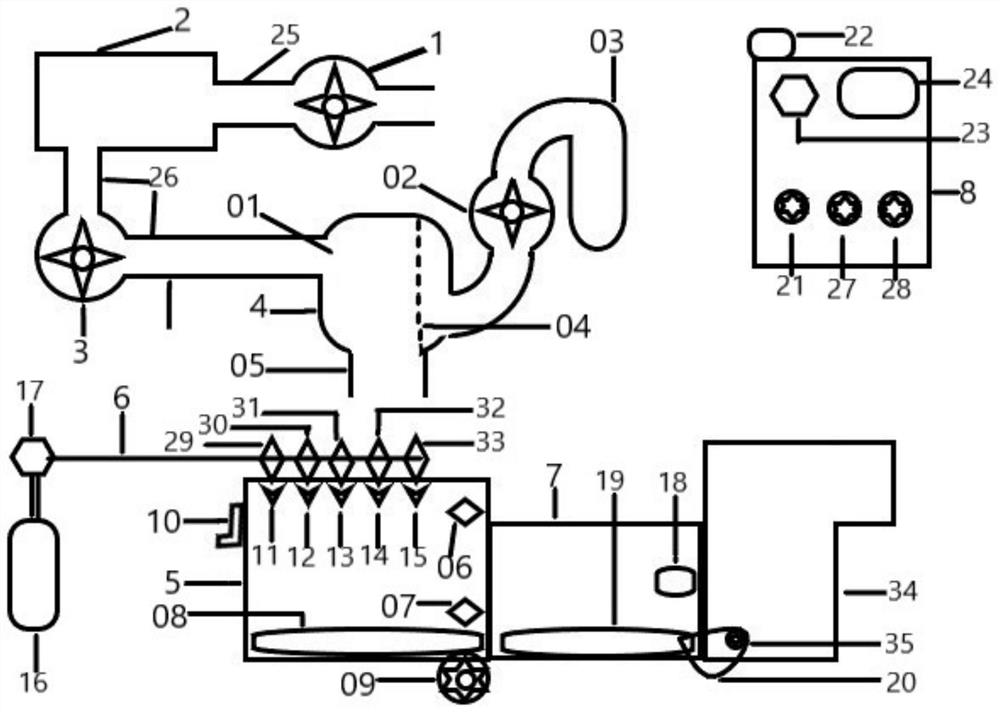

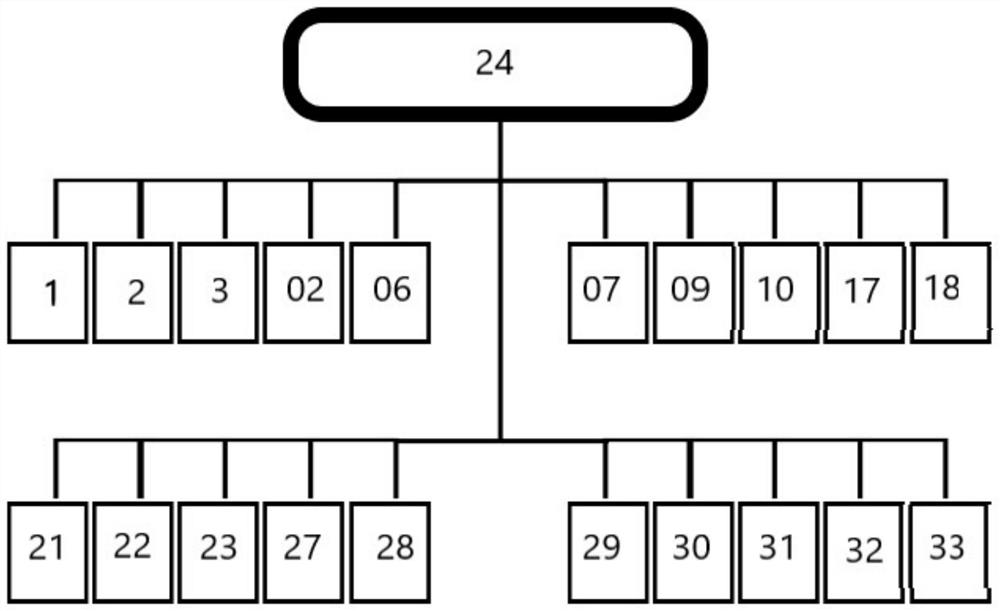

[0021]The intelligent storage bin of fluff raw materials uses 8-control box to control the operation of the total equipment. When the 07-lower sensor of the 5-storage bin fails to sense the raw material, it sends a signal to the 24-PLC controller on the 8-control box. The 24-PLC controller sends instructions to the 22-warning light to remind the user of the lack of raw materials. When the user presses the 27-working button on the 8-control box, each operating equipment runs in sequence, and the raw materials pass through the 1-feeding fan and the 25-feeding pipe. Transported to 2-opening machine, the raw materials after opening and dispersing are transported from 2-opening machine to 01-feed port on 4-dust collector through 3-feeding fan and 26-feeding pipe, 4-dust collector The 02-dust removal fan on the top sucks the dust raised by the 01-feed inlet into the raw material through the 04-isolation net to the 03-dust bag, and the raw material falls into the 5-storage bin below f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com