Low-bubble release paper and preparation process thereof

A preparation process and technology of release paper, applied in special paper, paper, papermaking and other directions, can solve the problems of affecting the performance, uneven thickness of the backing paper, reducing the peeling force of the release paper, etc., to reduce the probability of air bubbles, improve The effect of using performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

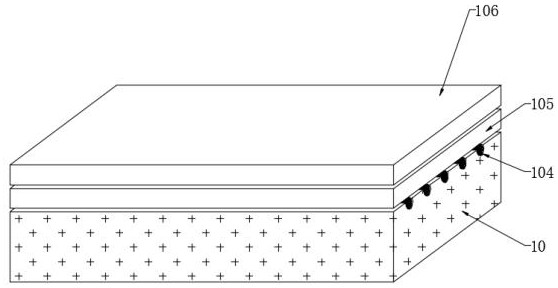

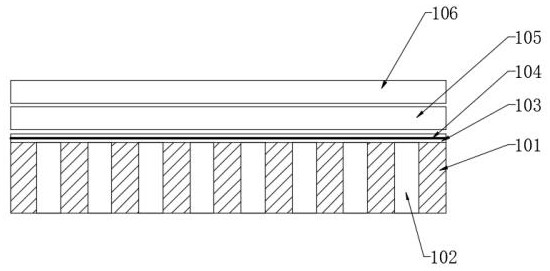

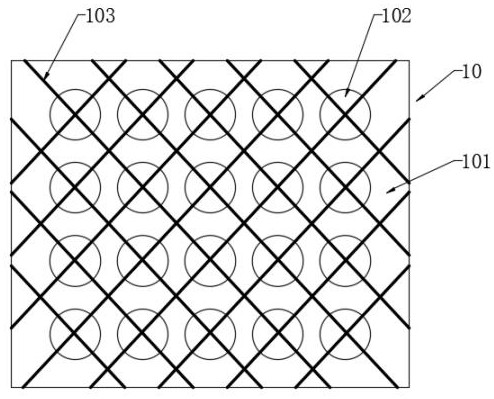

[0044] see Figure 1-3 , a low-bubble release paper, including a workbench 1, the release paper 10 includes a backing paper 101, the backing paper 101 is dug with a plurality of evenly distributed air vents 102, and the upper side wall of the backing paper 101 is dug with a plurality of cross The limiting cavity 103 is provided, the gas supply rope 104 is arranged inside the limiting cavity 103, the upper side wall of the backing paper 101 is provided with a coating layer 105, and the upper end of the coating layer 105 is coated with a silicone oil layer 106.

[0045] see Figure 5-9 , the pre-checking device includes a workbench 1, the upper side wall of the workbench 1 is fixedly connected with a plurality of connecting columns 11, the upper ends of the plurality of connecting columns 11 are fixedly connected with the same suspension board 12, and the lower side wall of the suspension board 12 is fixedly connected with multiple The drive tubes 2 are evenly distributed, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com