Fabricated fully-prefabricated concrete frame structure system and construction method

A prefabricated concrete and frame structure technology, which is applied to building components, building structures, floor slabs, etc., can solve the problems of difficult construction, increased cost, and increased cost, and achieve simple construction methods, easy quality control, and fast construction progress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

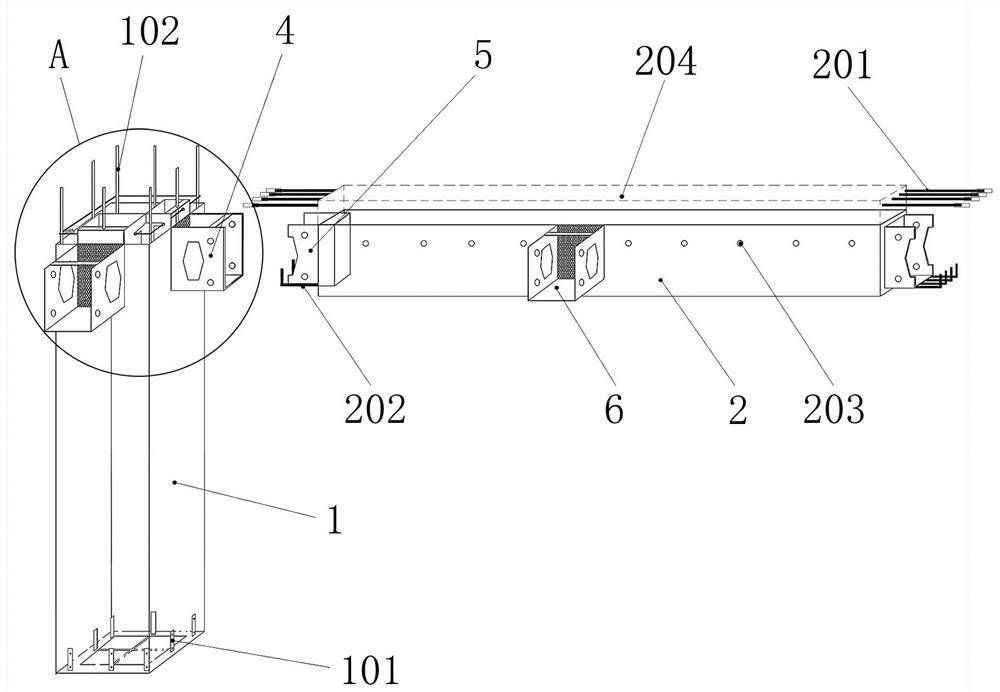

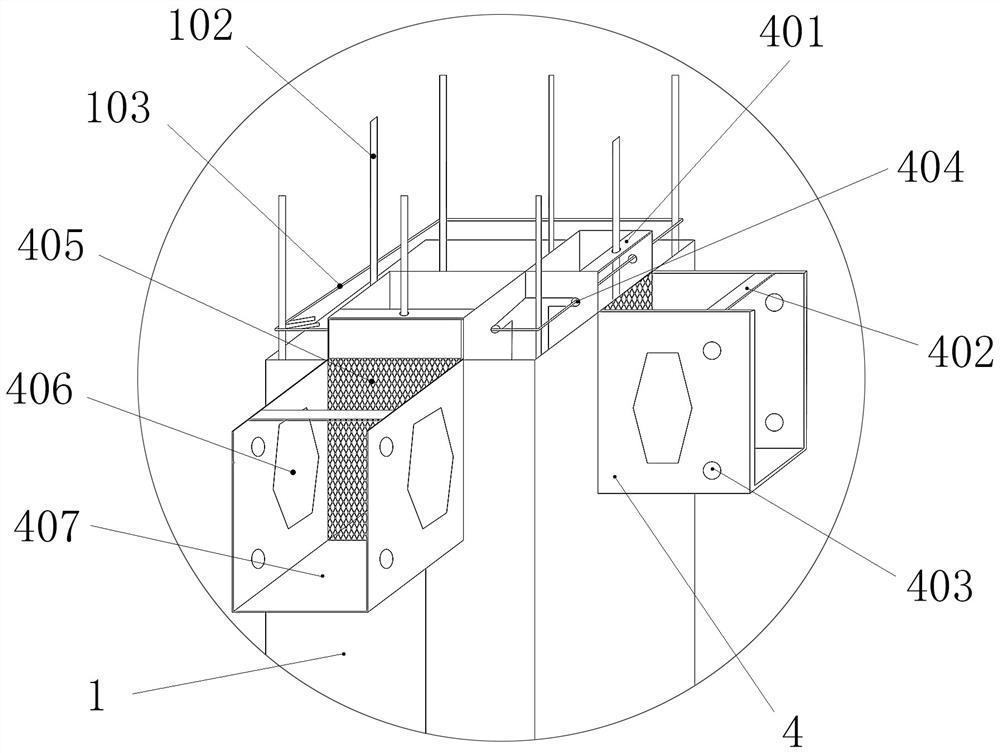

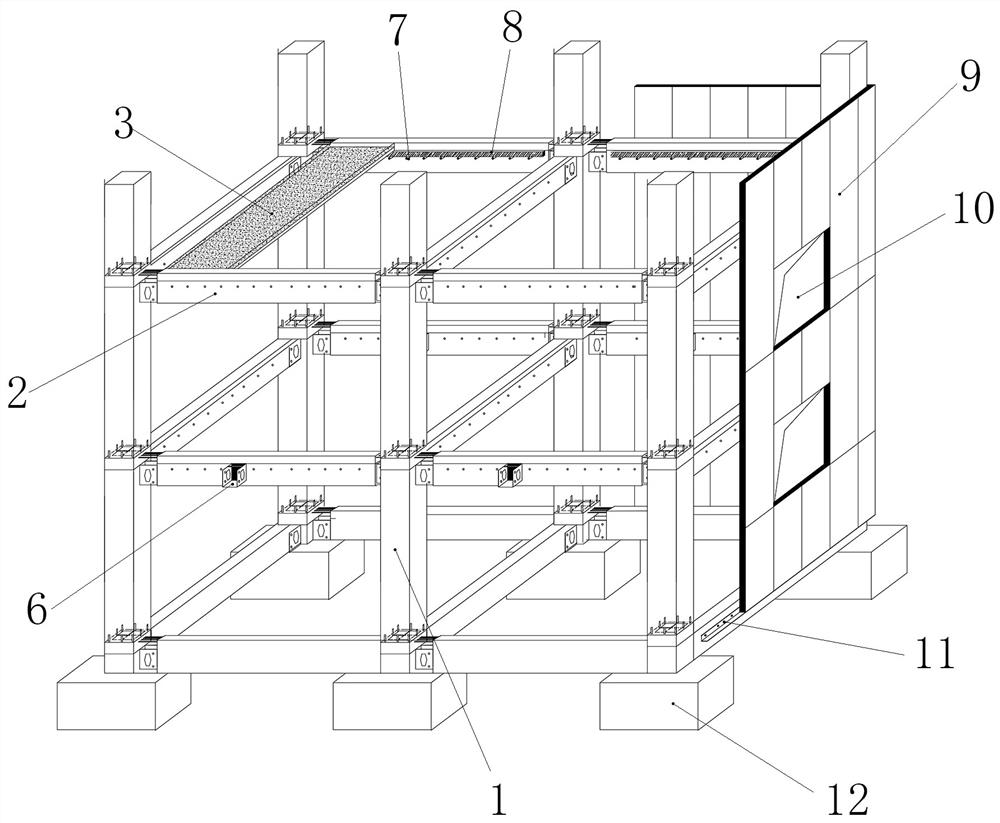

[0049] The assembled full-prefabricated concrete frame structure system, including prefabricated frame columns, prefabricated laminate, structural rectures, structural strokes, frame column grouting sleeve, prefabricated plate, prefabricated exterior wall thermos, wherein in the prefabricating frame column The upper portion of the upper is embedded having a laminated beam connection assembly, and the laminated beam connection assembly is composed of one to four U-shaped trusts 4 correspondingly set, and the number of prefabricated laminate 2 is connected to the prefabricated laminate 2 according to the prefabricated frame column. The number of type rejuvenation includes a "one word" type "L" type U-type Trust combination that connects two prefabricated laminated beams, and connects three "ding words" type U-type trust portions, connection of three prefabricated laminated beams. "Cross" type U-shaped bonding combination of four pre-laminated beams, etc .; the U-shaped tray includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com