Cantilever creeping formwork system

A climbing formwork and system technology, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and preparation of building components on site, which can solve the complex structure of assembly and use and reduce the construction progress , multiple components, etc., to achieve the effects of flexible use, prevention of slurry leakage and wrong platform, and high degree of standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

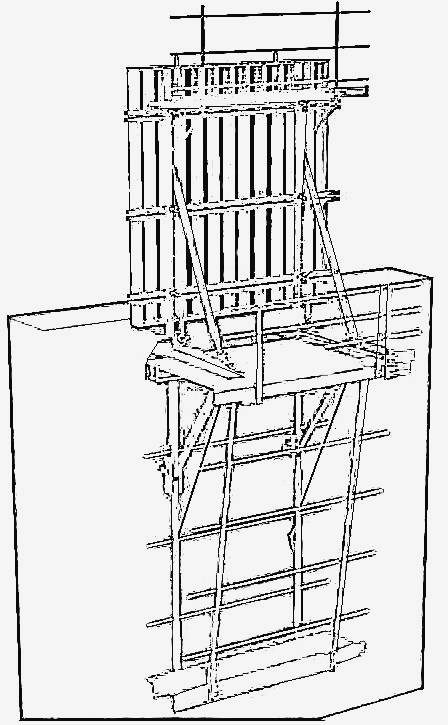

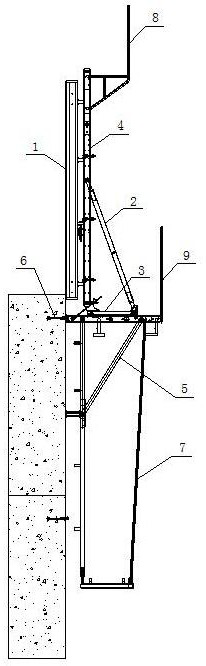

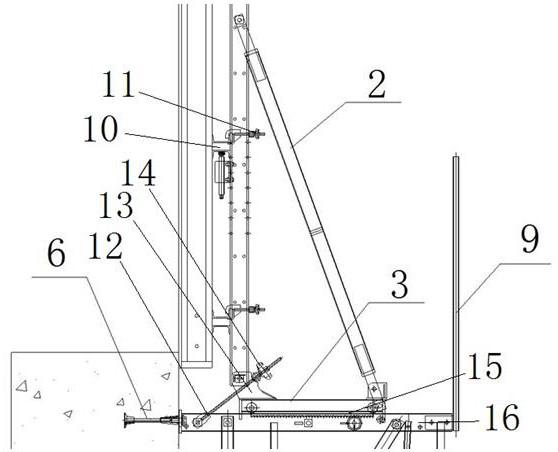

[0016] Such as figure 1 , figure 2 and image 3 The cantilever climbing formwork system shown includes formwork 1, diagonal bracing 2, rear moving device 3, vertical main back corrugation 4, load-bearing tripod 5, embedded part system 6 (cone system with anchor plate), hanging platform 7. Picking frame 8, platform pole 9, template regulator 10, back corrugated fastener 11 and frame plate 16; diagonal brace 2, backward moving device 3, vertical main back corrugated 4, load-bearing tripod 5, hanging platform 7 , cantilever frame 8, platform pole 9, template adjuster 10, back corrugated fastener 11 and frame plate 16 are assembled into a cantilever frame body, hung on the embedded system 6, and then the template 1 is passed through the back corrugated fastener 11 and the template The adjuster 10 is connected on the cantilever frame body for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com