Pre-shutdown control method and device and refrigeration equipment

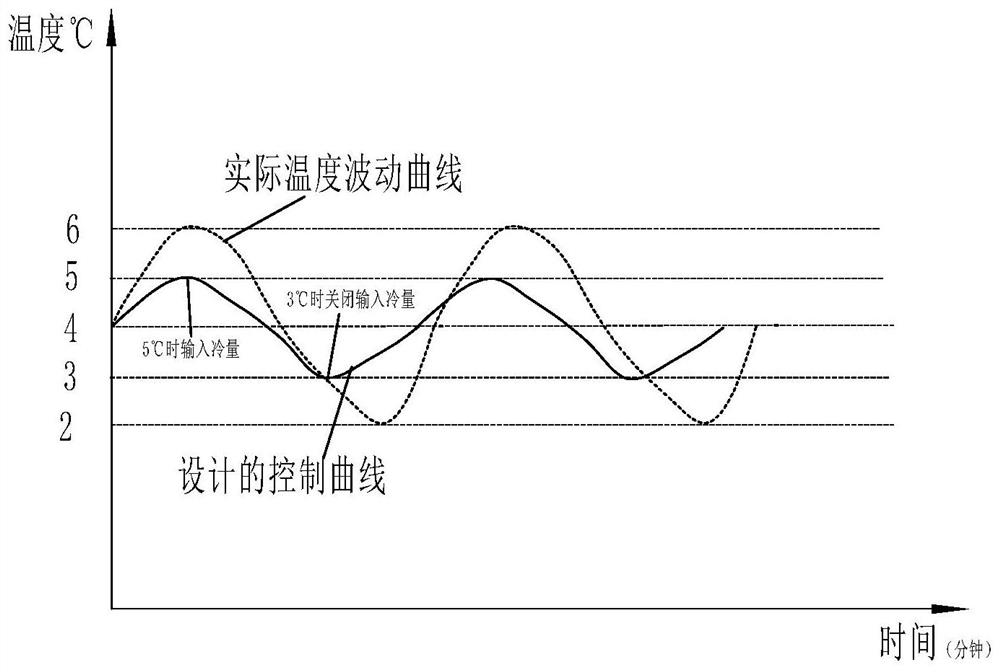

A technology for refrigeration equipment and shutdown, applied in the field of refrigeration equipment, pre-shutdown control methods, and devices, can solve problems such as precise control of cold storage rooms, achieve the effects of reducing costs, improving temperature uniformity, and helping to preserve freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

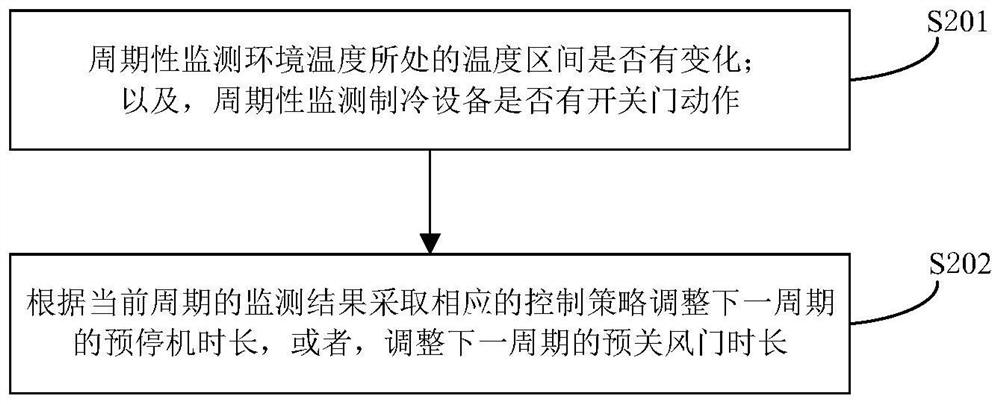

[0067] figure 2 is a flowchart of a pre-shutdown control method according to an embodiment of the present invention, such as figure 2 As shown, the method includes the following steps:

[0068] Step S201, periodically monitoring whether there is a change in the temperature range of the ambient temperature; and, periodically monitoring whether there is a door opening and closing action of the refrigeration equipment;

[0069] Wherein, the above-mentioned ambient temperature refers to the ambient temperature of the environment where the refrigeration equipment is located. If the refrigeration equipment is placed indoors, the above-mentioned ambient temperature can be understood as the indoor ambient temperature; if the refrigeration equipment is placed outdoors, the above-mentioned ambient temperature can be understood as The ambient temperature around the refrigeration equipment (eg, a preset range), such as the outdoor ambient temperature;

[0070] Step S202, adopting a co...

Embodiment 2

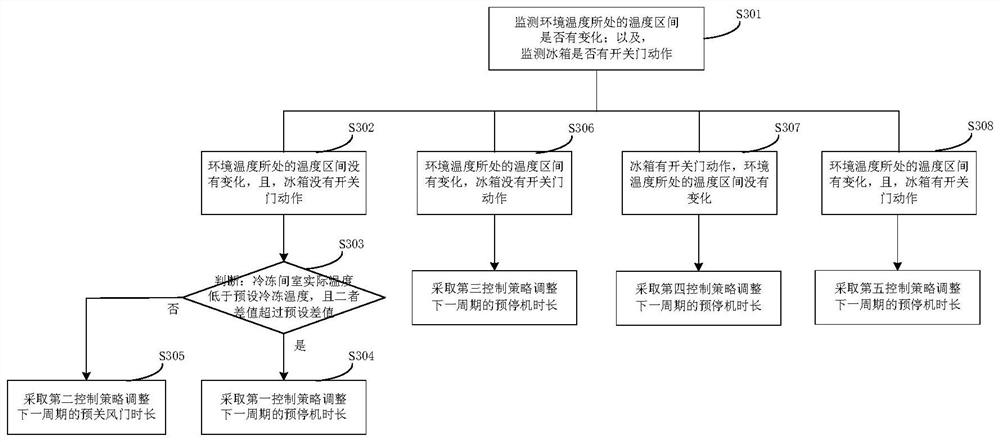

[0112] Taking a refrigerator as an example, the control logic of the present invention will be described in detail with reference to the accompanying drawings.

[0113] image 3 is a logic flow chart of refrigerator pre-stop control logic according to an embodiment of the present invention, such as image 3 As shown, the process includes:

[0114] Step S301 , in the current cycle, monitor whether the temperature range of the ambient temperature has changed; and monitor whether the door of the refrigerator is opened or closed.

[0115] In step S302, the temperature range of the ambient temperature does not change, and the refrigerator does not open or close the door.

[0116] Step S303, determine whether the actual temperature of the freezing compartment is lower than the preset freezing temperature, and the difference between the two exceeds the preset difference, for example, if the preset freezing temperature is -18°C, the actual temperature of the freezing compartment is ...

Embodiment 3

[0133] corresponds to figure 2 Introduced pre-shutdown control, this embodiment provides a kind of pre-shutdown control device, such as Figure 8 The structural block diagram of the pre-shutdown control device shown, the device includes:

[0134] The monitoring module 10 is used to periodically monitor whether there is a change in the temperature range of the ambient temperature; and, periodically monitor whether the refrigeration equipment has a door opening and closing action; wherein, the above-mentioned ambient temperature refers to the ambient temperature of the environment where the refrigeration equipment is located;

[0135] The adjustment module 20 is connected to the monitoring module 10, and is used to adopt a corresponding control strategy to adjust the pre-shutdown duration of the next cycle according to the monitoring results of the current cycle, or to adjust the pre-closing duration of the next cycle;

[0136] Among them, the pre-stop time is used to characte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com