Continuous beam hogging moment zone chlorine salt environment load holding experiment device and experiment method

A technology of negative bending moment zone and experimental device, applied in the field of engineering experiments, can solve the problems of inconstant load, heaviness, and high cost, and achieve the effects of convenient detection tools, accurate experimental results, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to achieve the above purpose and effects, the technical means and structures adopted in the present invention will be described in detail in terms of the features and functions of the preferred embodiments of the present invention in conjunction with the accompanying drawings.

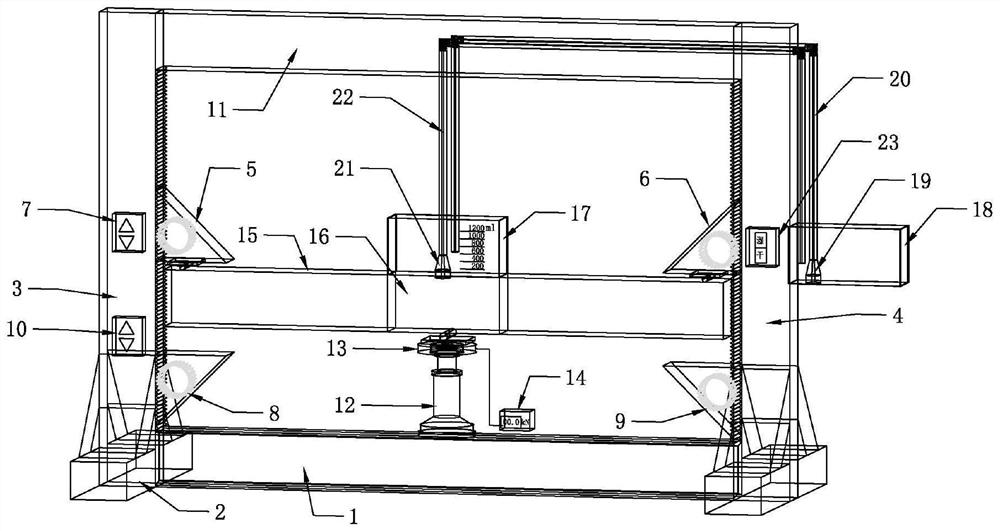

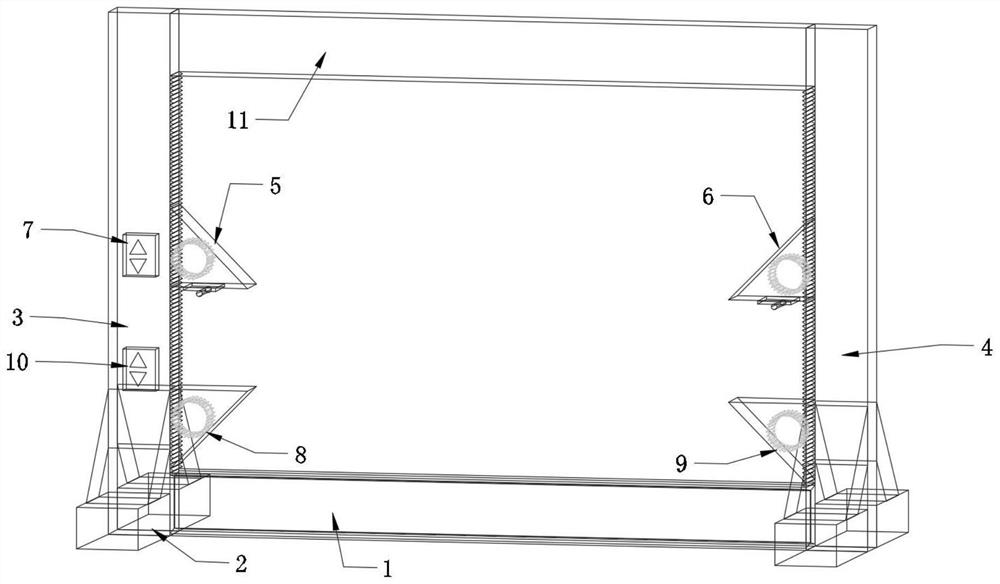

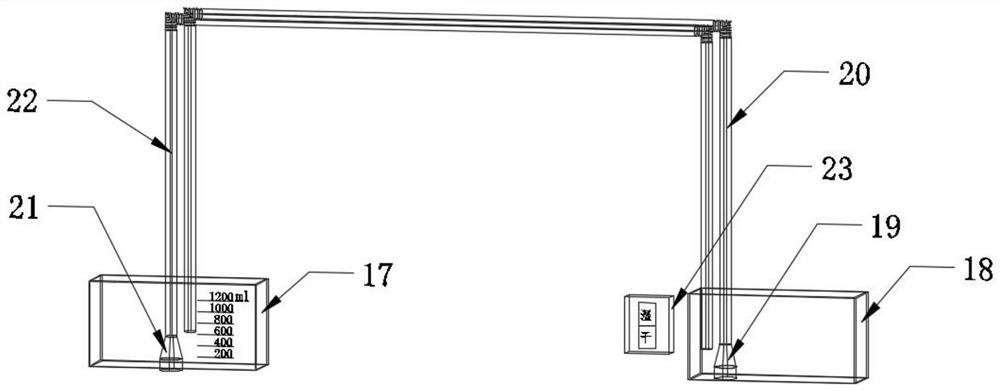

[0027] Such as Figure 1-4 As shown, the present invention provides a load-bearing experimental device in a continuous beam negative moment zone under a chloride-salt environment, including a high-rigidity main frame, a load system, an erosion system and a test beam 15, and the test beam 15 is detachably arranged on On the high-rigidity main frame; the load system is arranged on the high-rigidity main frame and below the test beam 15, and is used to apply a load to the test beam 15; the erosion system is arranged on the test beam 15 and has a built-in chlorine salt solution; The test beam 15 is a continuous beam meeting the design requirements.

[0028] Further, the high-rigidity main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com