Full-automatic drop hammer impact testing machine for pipes

A drop-weight impact test, fully automatic technology, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of small diameter range, hidden dangers, and complicated operation, so as to ensure reliability, eliminate hidden dangers, and avoid two problems. secondary impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

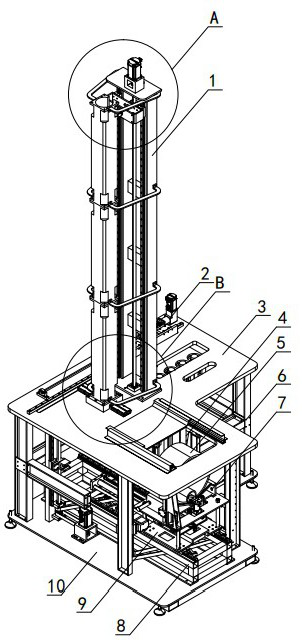

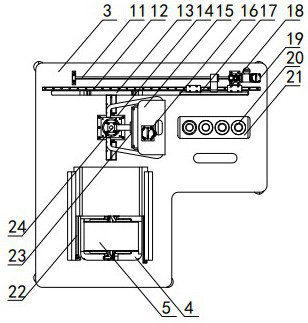

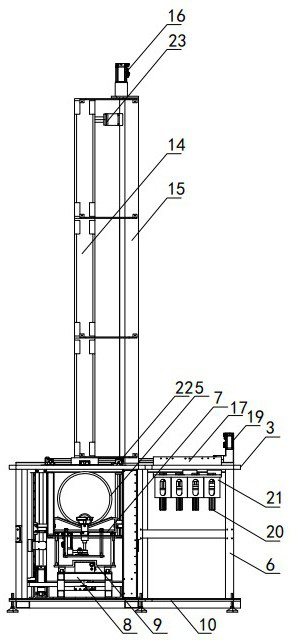

[0034] Figure 1~10 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~10 The present invention will be further described.

[0035] like figure 1 As shown, a fully automatic drop weight impact testing machine for pipes (hereinafter referred to as the testing machine) includes a top plate 3 and a bottom plate 10. Bar support column 6 is connected. On the front side of the surface of the top plate 3, there is a top plate opening 4 for putting in the pipe fittings 5 to be tested (two different thicknesses are provided in the figure), and on both sides of the top plate opening 4, there are mutually parallel baffle guide rails 22 (see figure 2 ), the baffle 30 used to block the roof opening 4 (see Image 6 ), the baffle plate 30 slides along the baffle guide rails 22 on both sides and is installed above the roof opening 4 through the baffle guide rails 22 on both sides.

[0036] A test port is also provided on the rear side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com