Online chromaticity detection device in naphtha heat exchange process

A detection device and naphtha technology, applied in the direction of color/spectral characteristic measurement, application of light to test fluid tightness, etc., can solve problems such as inaccurate measurement results, long result cycle, unstable light intensity change, etc., to achieve measurement Accurate results, improved measurement accuracy, and convenient inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further clarified below with reference to the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and not to limit the scope of the present invention.

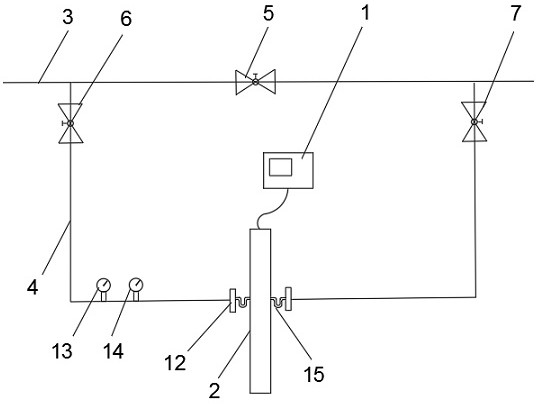

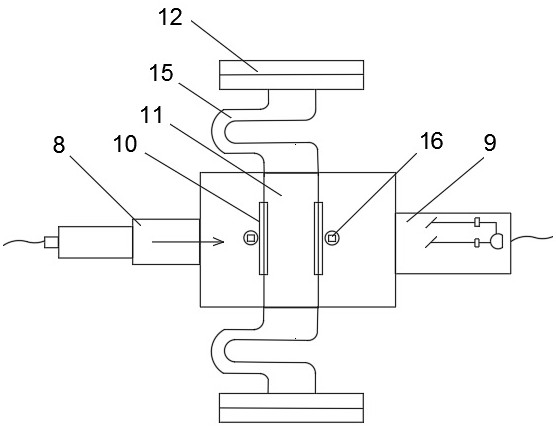

[0035] As shown in the figure, the on-line chromaticity detection device in the process of naphtha heat exchange according to the present invention includes a controller 1, an analyzer sensor 2, a main pipeline 3, a branch pipeline 4, a regulating valve 5, and a control valve 1 6. Control valve 2 7, the main pipeline 3 and the branch pipeline 4 are in a parallel structure, the analyzer sensor 2 is provided with a light source transmitter 8 and a receiver 9, and the light source transmitter 8 and the receiver 9 are arranged between A square medium channel 11 flows through the window 10. The outer ends of the medium channel 11 are provided with flanges 12 to connect with the branch pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com