Plating solution analysis system and dosing device

A technology of a dosing device and an analysis system, which is applied in the fields of analyzing materials, measuring devices, and material analysis by electromagnetic means, can solve the problems that the channels cannot be fully utilized, exceed the number of types, and the precision syringes are expensive. The effect of analyzing time, improving work efficiency, and high dosing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

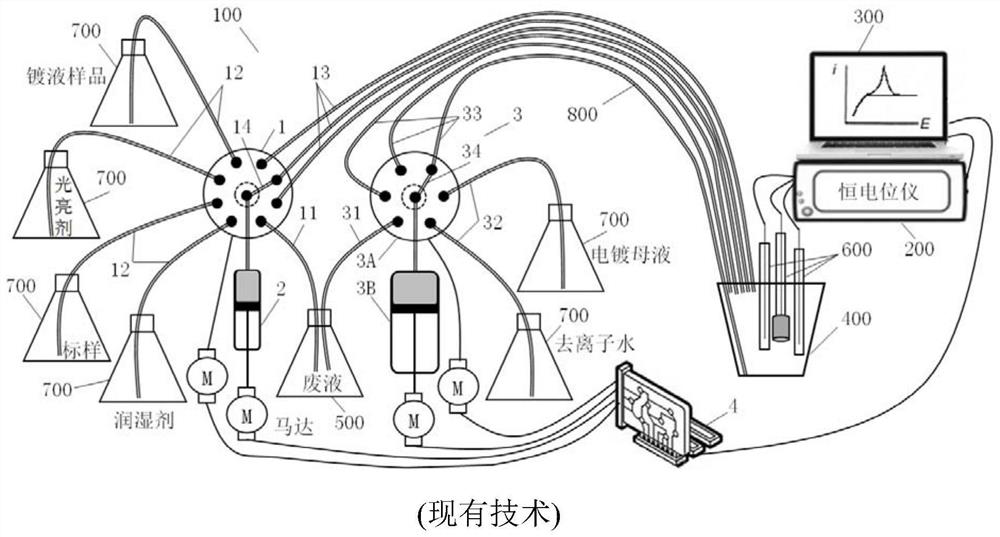

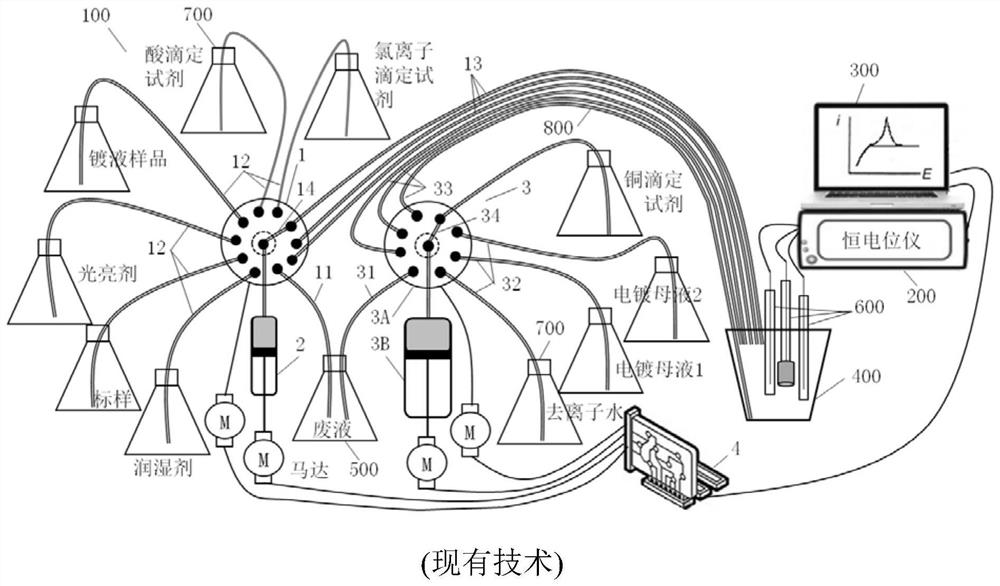

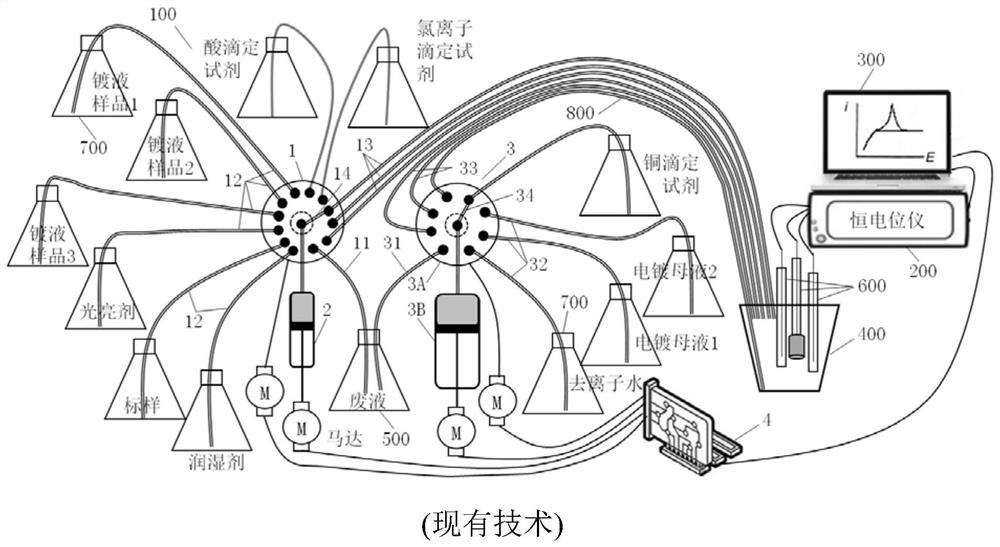

[0048] refer to figure 1 , this embodiment provides a plating solution analysis system. The plating solution analysis system includes a dosing device 100 , a potentiostat 200 , a computer 300 , an electrolyte analysis container 400 , a waste liquid container 500 , multiple electrodes 600 and multiple liquid containers 700 .

[0049] A plurality of electrodes 600 are located in the electrolyte analysis container 400 and can be connected to the potentiostat 200 . The computer 300 may specifically be a personal computer, and may process the data transmitted from the potentiostat 200 .

[0050] The waste liquid container 500 is used to accommodate waste liquid.

[0051] The liquid placed in each liquid container 700 includes one of plating solution sample, brightener, standard sample, electroplating mother solution, deionized water, chloride ion titration reagent, acid titration reagent, wetting agent and copper titration reagent.

[0052] refer to figure 1 , the dosing device...

no. 2 example

[0069] refer to Figure 4 The difference between this embodiment and the first embodiment is that: the large-capacity automatic controllable precision dosing unit 3 of the first embodiment includes a second automatic controllable multi-way valve 3A and a large-capacity automatic controllable precision syringe 3B; The large-capacity automatic controllable precision dosing unit 3 of the embodiment includes three peristaltic pumps. refer to Figure 4 , one side channel of a peristaltic pump is used as the second waste liquid discharge channel 31 , and the other side channel is used as the waste liquid suction channel 800 .

[0070] One side channel of the other two peristaltic pumps is used as the second liquid suction channel 32 , and the other side channel is used as the second liquid discharge channel 33 .

[0071] The controller 4 makes the three peristaltic pumps work respectively by controlling three driving mechanisms including motors, so as to realize suction and discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com