Detection device for escaping charged particle flow outside cutting area

A technology of charged particles and detection devices, applied in measurement devices, measurement of current/voltage, measurement of electrical variables, etc., can solve problems such as increasing measurement difficulty, affecting measurement accuracy, interfering with current, etc., to reduce the cost of detection equipment, suitable for The effect of wide range and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

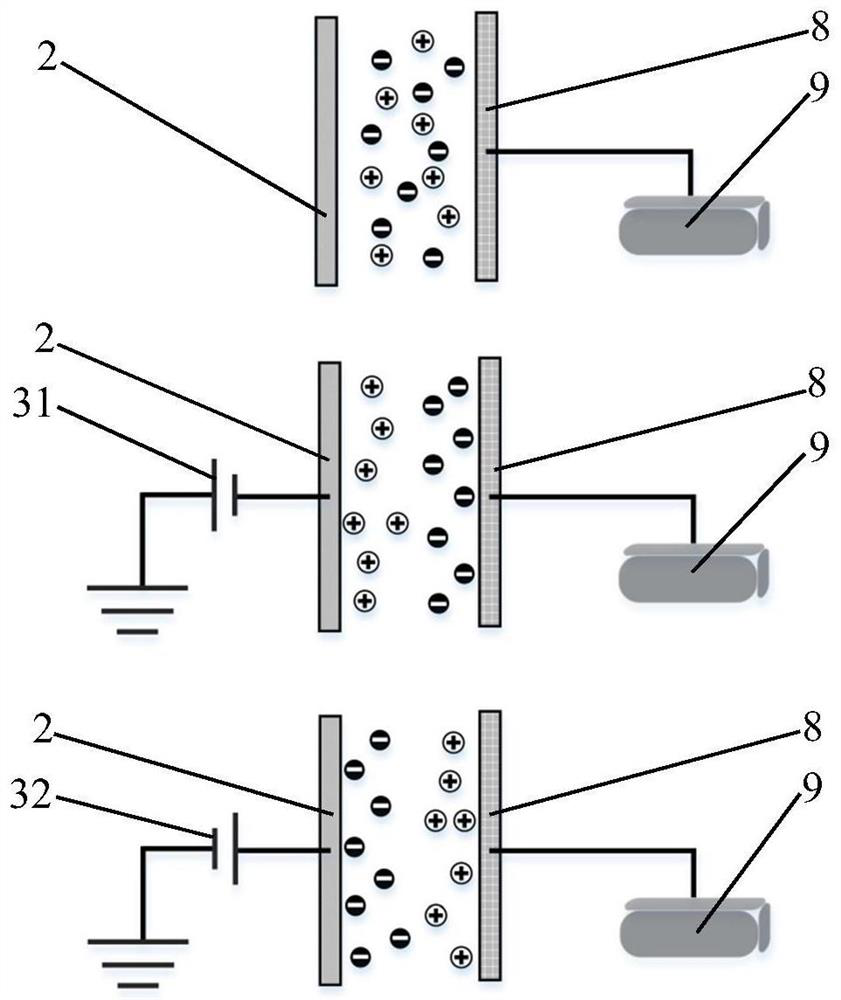

[0052] The bias electric field strength applied in the test is -700V / cm, at this time the polarity of the particles collected by the charged particle flow collection plate is negative. Figure 4 The cutting material shown in a and 4b is AISI 304 stainless steel, and the cutting depth is increased from 0.25mm in Fig. 4a to Figure 4 0.5mm of b; Figure 4 The cutting material shown in c and 4d is ABS, and the cutting depth is given by Figure 4 0.25mm of c increased to Figure 4 0.5mm of d.

[0053] It can be seen that as the cutting progresses, the current changes to the negative polarity more obviously, and the current intensity returns to zero after the cutting stops. The order of magnitude of the current intensity of the metal workpiece is 10 -9 A, while the magnitude of the current intensity of the ABS workpiece reaches 10 -8 a. When the cutting depth increases, the absolute value of the current intensity increases, and the current intensity for cutting AISI 304 chang...

Embodiment 1-2

[0055] The bias electric field strength applied in the test is +700V / cm, at this time the polarity of the particles collected by the charged particle flow collection plate is positive. Figure 5 The cutting material shown in a and 5b is AISI 304 stainless steel, and the cutting depth is increased from 0.25mm in Fig. 5a to Figure 5 0.5mm of b; Figure 5 The cutting material shown in c and 5d is ABS, and the cutting depth is given by Figure 5 0.25mm of c increased to Figure 5 0.5mm of d.

[0056] It can be seen that as the cutting progresses, the current changes to the positive polarity more obviously, and the current intensity returns to zero after the cutting stops. Compared with the negative polarity current, the overall positive polarity current intensity is smaller. When the cutting depth increases, the current intensity increases, and the current intensity for cutting AISI 304 is changed from 2.11×10 -9 A increased to 2.3×10 -9 A; The current intensity of cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com