Pixel-misplaced indium gallium arsenic linear array detector, detection method and indium gallium arsenic photosensitive chip

An indium gallium arsenic and detector technology, which is applied in the direction of photometry and radiation control devices using electric radiation detectors, can solve the problems of high missed detection rate, achieve the effect of improving image resolution and reducing the probability of missed detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

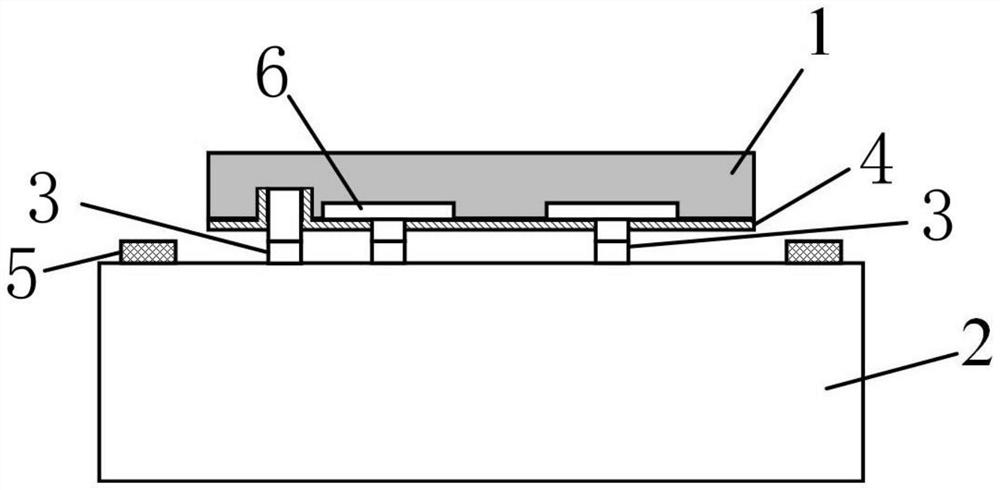

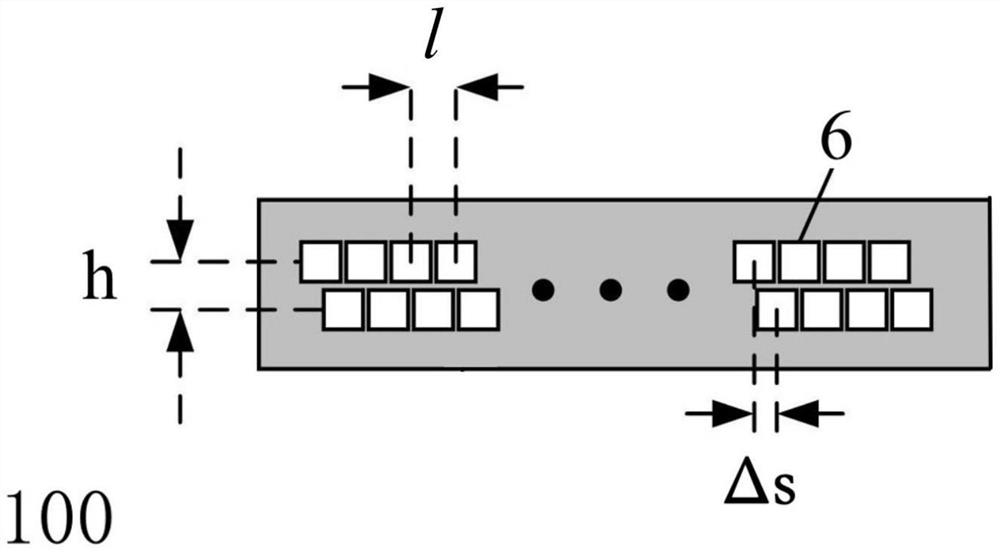

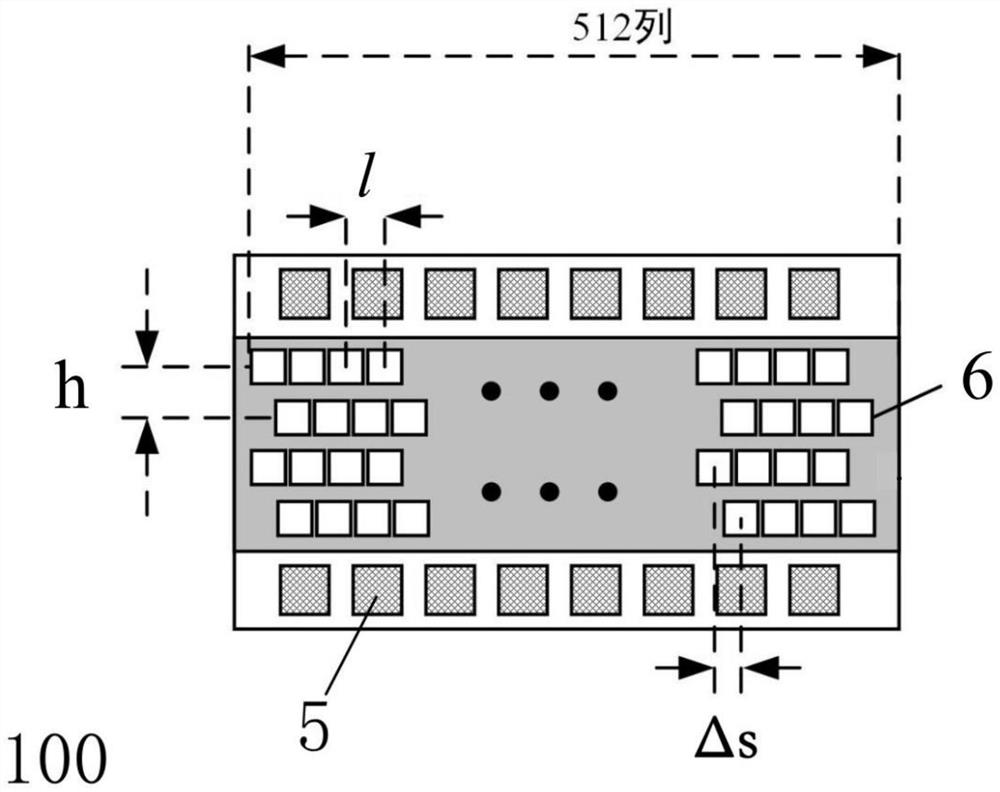

[0030] see figure 1 and 2 As shown, this embodiment specifically provides an InGaAs linear detector 100 with dislocated pixels. The InGaAs linear detector 100 includes an InGaAs photosensitive chip 1 . The InGaAs photosensitive chip 1 includes at least two rows of pixels of the same size arranged in parallel, and each pixel has a photosensitive area 6; the pixels in adjacent rows are staggered in the row direction. Since they are arranged in parallel, in the column direction, the projected length h of the center-to-center distance of any two pixels in different rows on the vertical plane is not less than the physical size of a single pixel in the column direction.

[0031] In this embodiment, an even-numbered pixel line column and an odd-numbered pixel line column are taken as an example for illustration. Since the pixels in these two lines and columns are misplaced along the row direction, the push-broom method In the process of detecting the same target in the imaging mode...

Embodiment 2

[0043] see Figure 5 As shown, this embodiment specifically provides a detection method based on an InGaAs linear detector, including steps:

[0044] S1. Push-broom imaging is performed on the detection object to obtain imaging data, and the imaging data is converted from pixel signals respectively obtained by the pixel elements of the InGaAs line detector.

[0045] S2. Determine abnormal values in the pixel signal according to the threshold range.

[0046] S3. According to the abnormal value, it is determined that the position corresponding to the detection object and the pixel is an abnormal position.

[0047] For step S1 , the InGaAs linear detector 100 in Embodiment 1 may be used to perform push-broom scanning on the test object to obtain imaging data and comprehensively obtain relevant optical features of the test object. In a preferred manner, the pixel elements of each row and column of the InGaAs linear column detector 100 are arranged equidistantly along the row d...

Embodiment 3

[0052] This embodiment specifically provides an InGaAs photosensitive chip, which includes at least two rows of pixels of the same size arranged in parallel; and the pixels in adjacent rows are dislocated along the row direction.

[0053] As a preferred implementation manner, it may be the InGaAs photosensitive chip 1 in Example 1.

[0054] The InGaAs photosensitive chip of this embodiment forms a reasonable dislocation structure by setting pixels in two adjacent rows, and can effectively use the pixels in adjacent rows to achieve complementary imaging of the detection object, avoiding the The imaging gap does not respond to incident light, which significantly reduces the detection system's failure to detect abnormalities in the scene, and can improve the image resolution through image fusion processing, thereby improving the detection accuracy and expanding the application range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com