Intelligent internet-of-things high-explosive switch

A technology of smart things and the Internet of Things, applied in the direction of switchgear, pull-out switchgear, grounding device of switchgear, etc., can solve problems such as accidents, increased electric field strength, intelligent analysis and diagnosis of high-explosive switches, and achieve high safety , The effect of troubleshooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

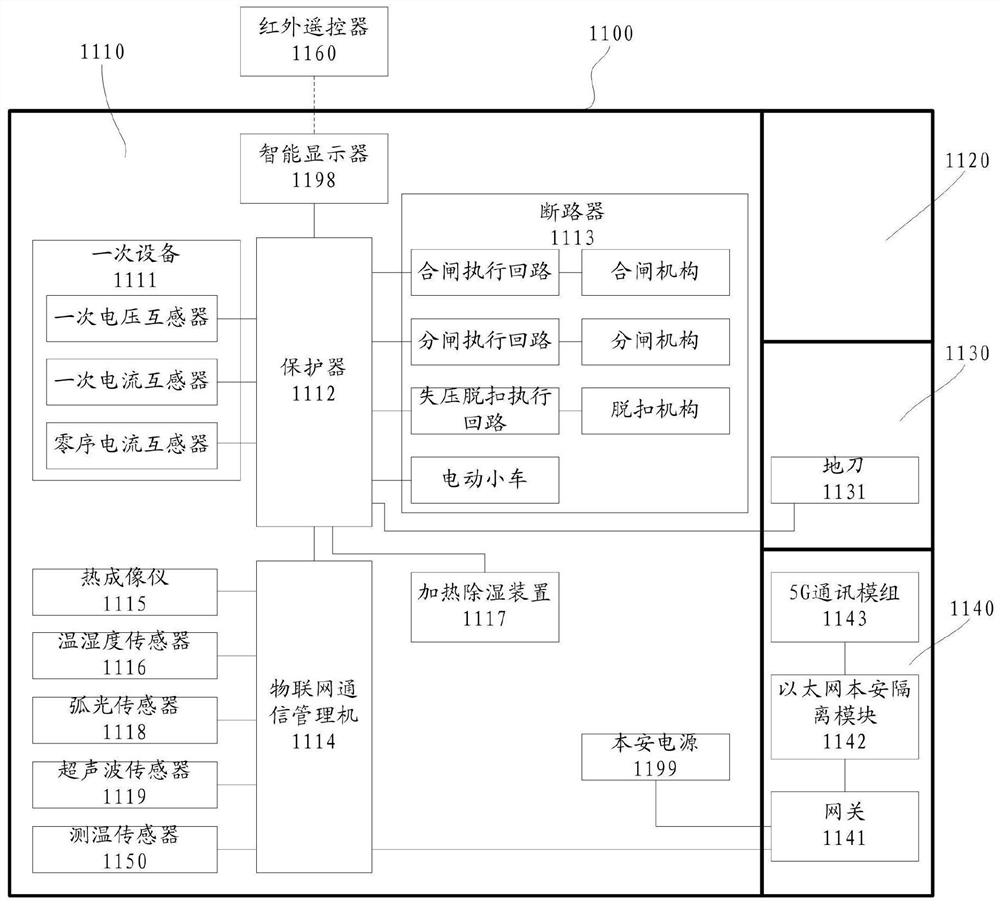

[0026] Such as figure 1 As shown, the embodiment of this specification provides a smart high-explosion switch for the Internet of Things, including an explosion-proof housing 1100 arranged on a base.

[0027] The explosion-proof housing 1100 has a front cavity 1110 and a rear cavity, and the rear cavity includes a wiring cavity 1120 , a ground knife cavity 1130 and an intrinsically safe cavity 1140 .

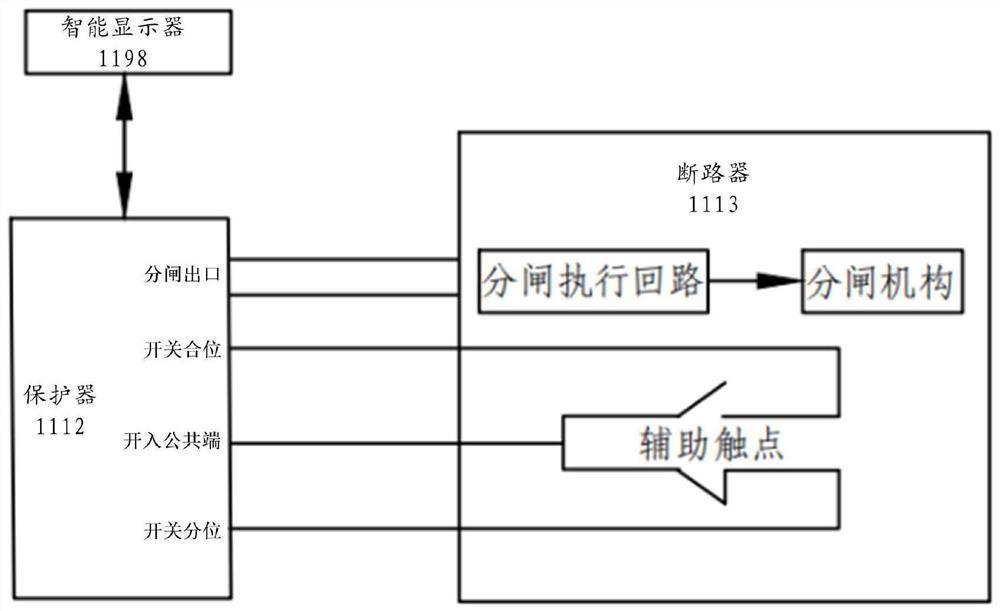

[0028] The front cavity 1110 is equipped with primary equipment 1111, protector 1112, circuit breaker 1113, IoT communication management machine 1114, thermal imager 1115, temperature and humidity sensor 1116, heating and dehumidification device 1117, arc sensor 1118, ultrasonic sensor 1119, and smart display 1198 and intrinsically safe power supply 1199.

[0029] The wiring chamber 1120 is provided with cable connectors, the ground knife chamber 1130 is provided with a ground knife 1131 , and the intrinsically safe chamber 1140 is provided with a gateway 1141 for accessing ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com